Open Access

Open Access

ARTICLE

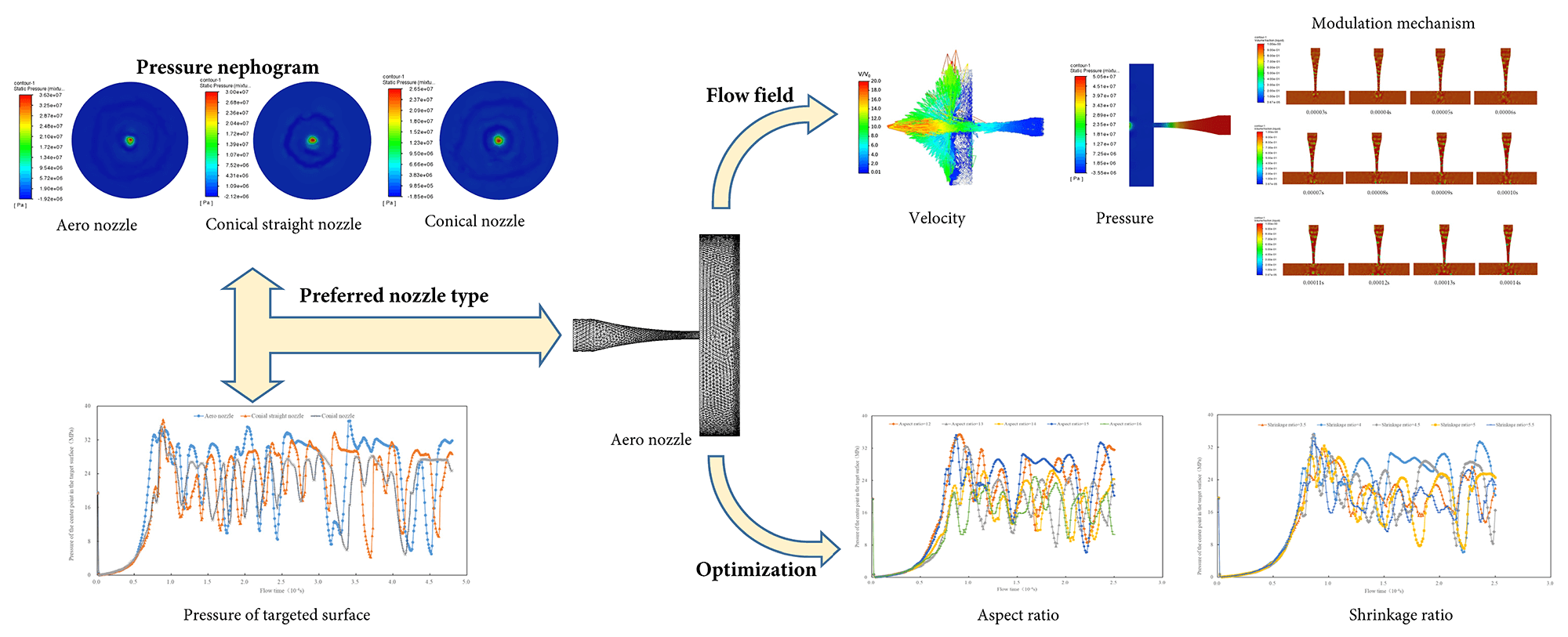

Structural Optimization of Nozzles for Gas-Liquid Two-Phase Jets

1 School of Petroleum Engineering, Shandong Institute of Petroleum and Chemical Technology, Dongying, 257061, China

2 School of Petroleum Engineering, China University of Petroleum (East China), Qingdao, 266580, China

3 Dongying Academy of Science and Technology, China University of Petroleum (East China), Dongying, 257061, China

4 CNOOC (Tianjin) Oilfield Chemical Co., Ltd., Tianjin, 300451, China

* Corresponding Author: Jian Zhao. Email:

Fluid Dynamics & Materials Processing 2025, 21(12), 2963-2980. https://doi.org/10.32604/fdmp.2025.073836

Received 26 September 2025; Accepted 21 November 2025; Issue published 31 December 2025

Abstract

Gas–liquid two-phase jets exhibit markedly enhanced impact performance due to the violent collapse of entrained bubbles, which generates transient microjets and shock waves. The geometry of the nozzle is a decisive factor in controlling jet formation, flow modulation, and impact efficiency. In this work, the structural optimization of gas–liquid two-phase nozzles was investigated numerically using the Volume of Fluid (VOF). Simulation results show that the aero-shaped nozzle delivers a significantly stronger impact on the target surface than conventional geometries. Specifically, its impact pressure is 21% higher than that of a conical straight nozzle and 37% higher than that of a conical nozzle. The aero nozzle not only increases peak impact pressure but also sustains it over a longer duration, leading to an overall improvement in energy transfer efficiency. Parametric analyses further reveal the key geometric conditions governing performance. When the nozzle curvature is set to 0.01, the jet achieves a higher and more stable surface pressure profile, maintaining elevated impact for a prolonged period. At an aspect ratio of 15, the jet exhibits pronounced pulsation under high pressure, thereby enhancing impact intensity. The contraction ratio exerts a non-monotonic influence: as it increases, impact pressure initially rises and subsequently declines, with an optimal value of 4 yielding the highest and most persistent impact pressure. Likewise, when the ratio of inlet length to outlet diameter is 2.5, the jet demonstrates the strongest impact on the target surface.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools