Open Access

Open Access

REVIEW

Research Progress of Nanotechnology on Efficient and Green Technologies for Wood Preservation: A Review

1 College of Chemistry and Chemical Engineering, Zhongkai University of Agriculture and Engineering, Guangzhou, 510225, China

2 Guangdong Provincial Key Laboratory of Silviculture, Protection and Utilization, Guangdong Academy of Forestry, Guangzhou, 510520, China

* Corresponding Authors: Wenqing Xiao. Email: ; Guijun Xie. Email:

# Authors have contributed equally

(This article belongs to the Special Issue: Modification and Functionalization of Wood)

Journal of Renewable Materials 2025, 13(4), 699-718. https://doi.org/10.32604/jrm.2025.058349

Received 10 September 2024; Accepted 03 January 2025; Issue published 21 April 2025

Abstract

Wood, recognized as a renewable and environmentally sustainable material, plays a crucial role as an alternative energy resource within the construction industry. However, it is highly susceptible to mold and decay fungi, which can lead to surface discoloration and potentially compromise the structural integrity of wood. The advancement of nanotechnology has introduced innovative strategies for wood protection, enhancing its performance while imparting additional properties. Various approaches including nanosized metals, polymer nanocomposite and coating treatments are actively being explored in this field. Furthermore, integrating bio-based materials with nanotechnology offers a green and sustainable method for wood preservation. This paper provides an analysis, discussion, and synthesis of the applications of nanotechnology in wood protection along with its antifungal mechanisms, thereby contributing novel insights into the research landscape surrounding this topic.Keywords

Wood, as a structural material, is easily processed and sourced from renewable resources [1,2]. It is an environmentally sustainable material, characterized by its abundant availability and biodegradable properties [3–5]. As one of the most widely used forest products worldwide, wood is employed in a broad spectrum of construction projects [6].

Zhang et al. [7] emphasize that manufacturing and construction are significant sources of CO2 emissions, as both industries are resource-intensive and emissions-heavy. In contrast to energy-intensive building materials, wood offers a viable solution for reducing carbon emissions in the construction sector [8]. To ensure its effectiveness as a building material, it is crucial to prevent mold growth on wood surfaces and to select nontoxic compounds for indoor protection against degradation [9].

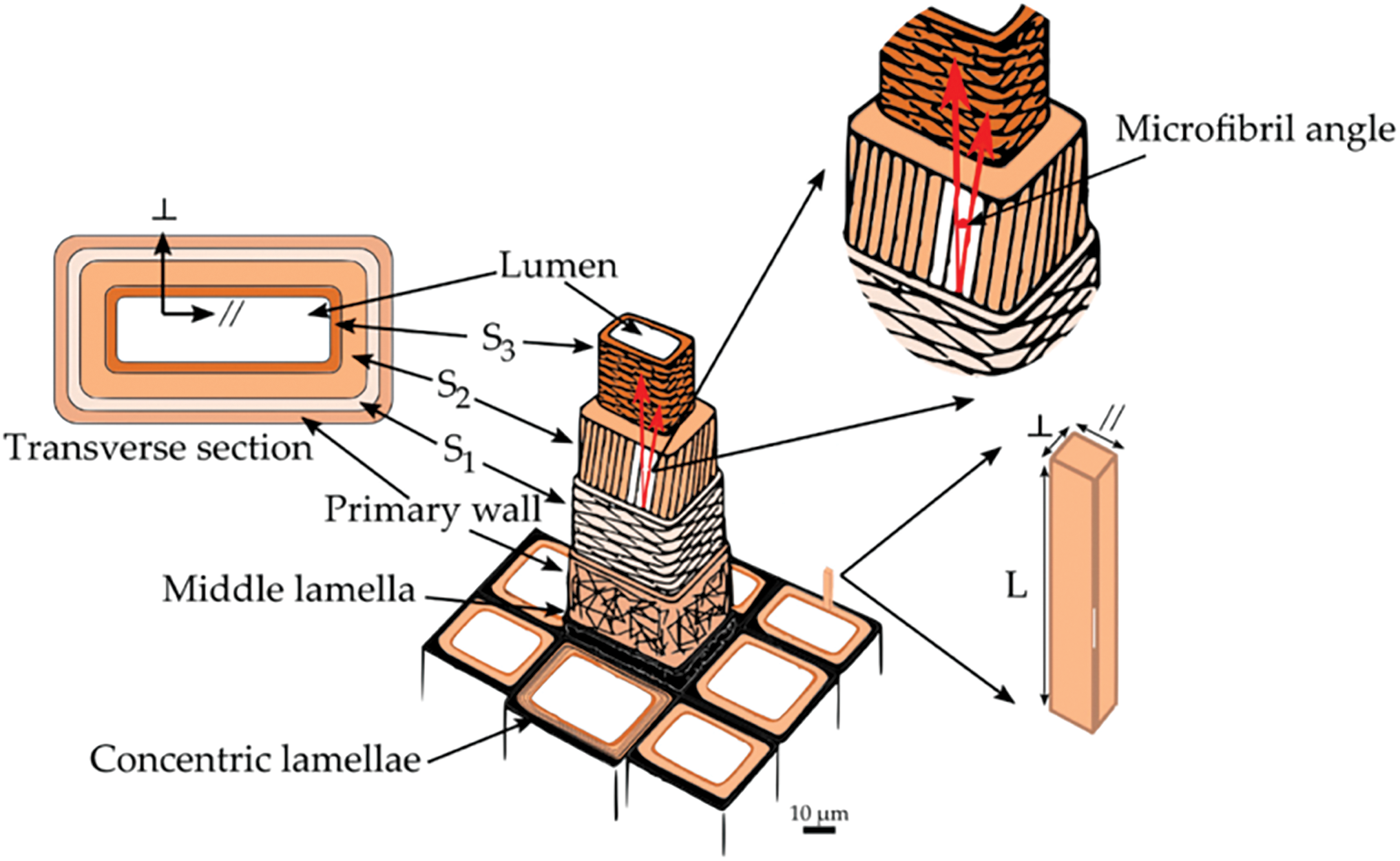

The primary constituents of wood cell walls are three main substances: cellulose, hemicellulose, and lignin [10]. Fig. 1 illustrates the structure of wood cells, with each individual cell conceptualized as a hollow tube with walls composed of several layers whose main component is cellulose. The adhesion between cells is facilitated by the outermost layer, which is primarily composed of lignin, along with some hemicellulose. At the center of each wood cell is a void known as the lumen, typically filled with water or air [11]. The high hydroxyl (-OH) content in both cellulose and hemicellulose imparts excellent hygroscopic and hydrophilic properties to wood [12]. Mold growth poses a significant challenge in wooden structures, especially in conditions of excessive humidity [13]. Johansson et al. [9] investigated the critical moisture content for mold contamination across ten building materials, finding that pine sapwood was the most susceptible to mold contamination, with a moisture content range of 75%–80% at 22°C and 85%–90% at 10°C.

Figure 1: Schematic of wood cell wall layers. The patterns in the primary, S1, S2, and S3 cell walls represent cellulose microfibril orientations. The parallel (//) and perpendicular (⊥) directions in the cell wall are defined in the transverse plane relative to the lumen surface. The cell wall longitudinal (L) direction is defined along the longitudinal axis of the cell. Adapted with permission from Reference [11]. Copyright ©2019, MDPI publishing

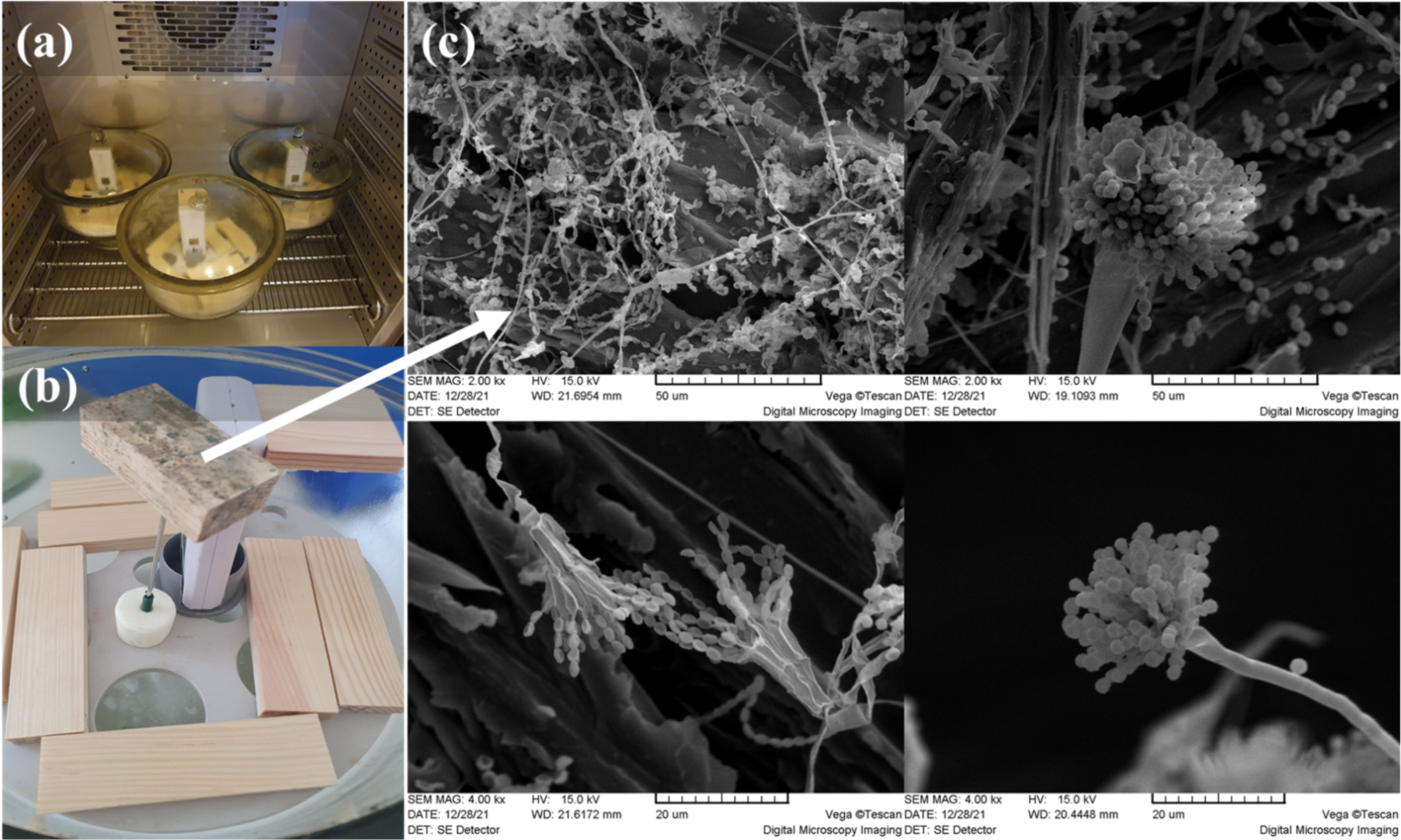

The growth of mold on wood indoors can lead to the contamination of air with toxigenic fungal spores, fragments, mycelium, and metabolic products, all of which can cause allergic reactions and, in some cases, serious illness [14,15]. As shown in Fig. 2, Kuka et al. [15] simulated constant environmental conditions to investigate the impact of initial moisture content in wood and spore contamination on indoor mold development. The results indicated that pre-wetting wood specimens significantly accelerated mold growth at a temperature of 10°C. Under SEM, the mycelium and spores of contaminated wood were clearly visible, with a detrimental effect on indoor air quality. Another serious consequence is the discoloration of wooden structures due to mold growth [16]. Mold growing on wood surfaces typically damages its appearance by producing pigments and colored spores without compromising the structural integrity of the wood [17].

Figure 2: An experiment simulating wood infestation by mould under specific climatic conditions: (a) test containers in a climate chamber; (b) setup of the test with mould-infected wood; (c) SEM images of the mould-infected wood specimen. Adapted with permission from Reference [15]. Copyright ©2022, MDPI publishing

Fungi that decompose wood are capable of breaking down the lignin barrier, leading to decay and often resulting in the complete mineralization of the lignified wood cell walls. Fungi that actively break down the structure of wood can be classified into several groups, including white rot fungi, brown rot fungi, and soft rot fungi [18]. These fungi produce specialized enzyme systems that degrade the cell walls of wood [19,20].

Various protective coatings and biocides are chemical strategies used to protect wood from microbial degradation [21]. Chromated copper arsenate (CCA) is a well-known example of traditional commercial preservatives, which have been widely used in the past [22]. However, the use of conventional wood preservatives is increasingly restricted due to their heavy metal content, which poses risks to human health and ecosystems [23]. Consequently, there is an urgent need to develop new wood preservatives that are highly toxic to microorganisms while being safe for humans and animals [21,24].

Chromated copper arsenate (CCA) is a typical copper-based preservative that has largely been replaced by copper azole (CA) and alkaline copper quaternary (ACQ) due to concerns about toxicity [25]. Studies have indicated that copper leaching from ACQ-treated wood exceeds that from CCA-treated wood, potentially contributing to water and soil pollution [26–28]. Lin et al. [29] investigated the copper leaching rates of softwood specimens vacuum-treated with ACQ and CA, revealing that the leaching rate for CA-treated wood was higher than that for ACQ-treated wood. Micronized copper (MC), based on nanoparticle formulations, consists of particles ranging in size from 10 to 700 nm and the copper leaching from MC-treated wood is lower than that from CCA-treated wood [30–32]. The use of nanoscale wood preservatives offers a promising alternative to traditional preservatives.

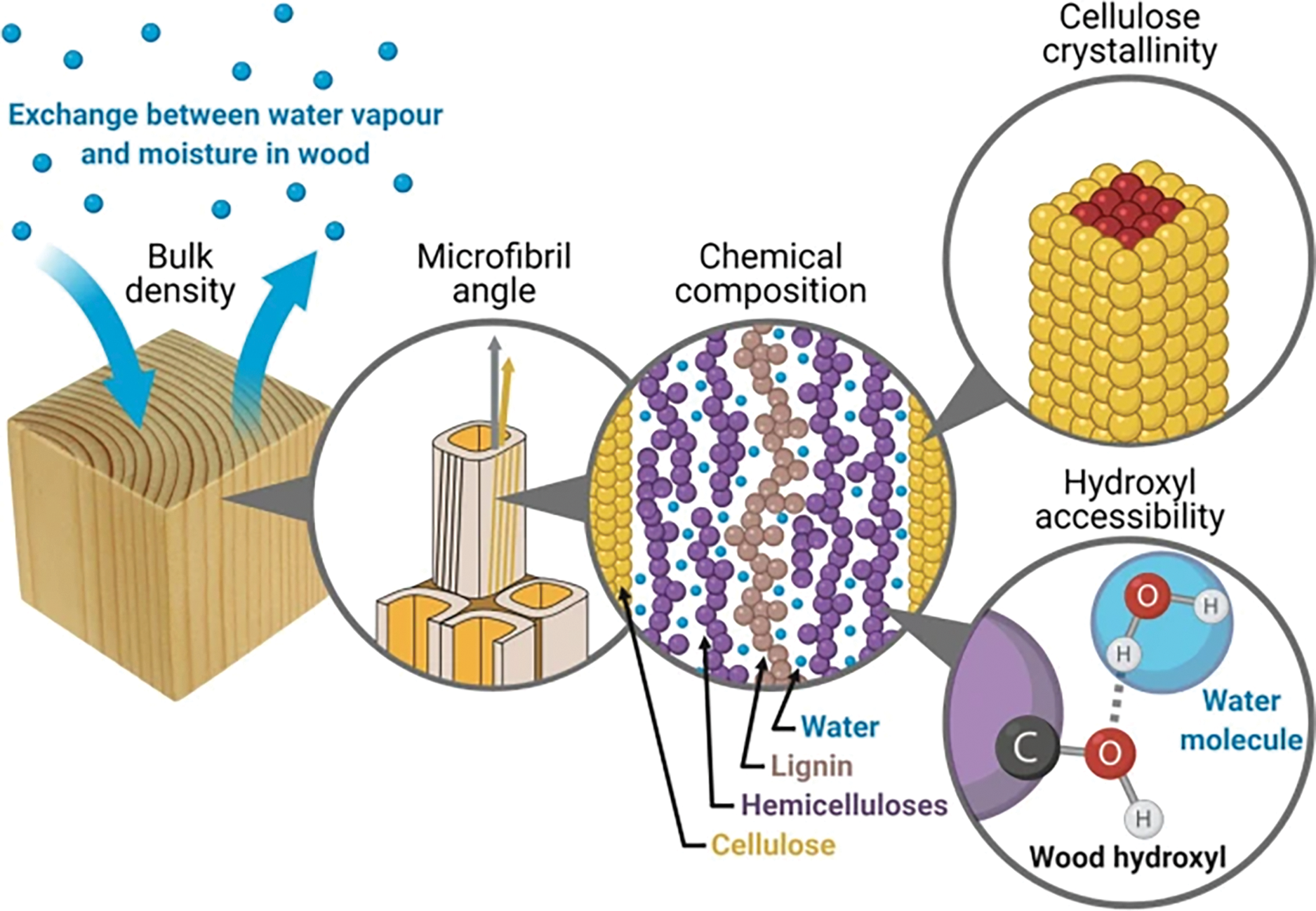

Wood is hygroscopic due to the presence of hydroxyl groups. Various hydrophobic treatments have proven effective in enhancing its durability and producing hydrophobic wood [21]. As illustrated in Fig. 3, water sorption within the cell walls of wood is attributed to these hydroxyl groups, which significantly influence its physicochemical properties [33]. A widely used chemical method for preparing hydrophobic wood is acetylation, in which hydroxyl groups react with acetic anhydride or isopropyl acetate to form acetates with hydrophobic characteristics [34,35]. Additionally, thermal modification can reduce the hygroscopic behavior of wood [36]. During the heating process, the degradation of hemicellulose and the amorphous regions of cellulose, along with condensation reactions involving lignin, lead to a reduction in the number of hydroxyl groups in wood [37–40]. Lukawski et al. [41] applied carbon nanotubes (CNTs) as a surface treatment to enhance the water repellency of wood and suggested that recent advancements in nanotechnology could address challenges related to wood hydrophobicity.

Figure 3: Schematic overview of investigated characteristics from the tissue-scale (left) to the nano-scale (right). Adapted with permission from Reference [33]. Copyright ©2022, Springer Nature publishing

Nanotechnology is a multifaceted field that integrates various scientific and technological disciplines, aiming to develop novel and enhanced materials with significant functionalities and unique chemical and physical properties [42]. The application of nanotechnology has provided innovative solutions to overcome the limitations of wood, wood-based composites, and other lignocellulosic materials. Due to their diminutive size and high surface area-to-volume ratio, nanoparticles (NPs) can easily penetrate wood pores, thereby enhancing the properties of the material and yielding high-performance superior quality products [43]. It is essential to emphasize that wood modification should adhere to the principles of green chemistry, utilizing bio-based polymers in combination with nanoparticle technology to minimize the overall environmental impact [44].

Whether through the application of antiseptic agents or the enhancement of hydrophobic properties, reducing the water content of wood via pretreatment is a crucial step. These methods are not only highly effective in lowering moisture levels, but also play a key role in preserving the volume and strength of the wood [45].

The relationship between wood and chemistry is fundamentally important for protecting wood in an environmentally friendly manner, extending its lifespan, conserving natural resources, and enhancing its overall value [12]. This study focuses on the primary components of wood cell walls while evaluating the strengths and weaknesses of various techniques for preventing mold formation. The review comprehensively analyzes, discusses, and synthesizes technical research related to wood preservation mechanisms. Its objective is to inform strategies for wood protection and offer innovative approaches for researchers working to mitigate mold issues.

2 Bio-Based Materials for Wood Protection

Biobased materials are derived from renewable biomass sources, including grains, legumes, straw, bamboo, wood powder, and animal fur waste. These materials represent a novel category that can be produced through biological, chemical, physical, and other processes. They primarily include bioplastics, biobased platform compounds, biomass functional polymers, and other products characterized by their environmentally friendly properties and biodegradability [46].

Plant polyphenols can serve as raw materials for constructing functional material coatings. Liu et al. [47] described the development of a rough hierarchical structure on the wood surface through the application of wood polyphenols. Rutin was used to create metal-polyphenol networks (MPNs) incorporating various metal ions such as Fe(III), Fe(II), Al(III), and Cu(II). The resulting materials exhibited excellent self-cleaning capabilities, anti-fouling properties, and remarkable resistance to both acids and alkalis, as well as impregnation by organic solutions.

Organic acids are biological derivatives of plant-based biomass, primarily derived from cellulose [48]. Citric acid (CA) can act as a cross-linker and bulking agent in wood treatment. To achieve a more flexible cross-linked network, low molecular weight polyols need to be added [49]. Marc-Andre Berube et al. [50] employed citric acid and glycerin to impregnate and modify lodgepole pine and white pine. The polymer was effectively incorporated into the wood structure, enhancing its dimensional stability. The carboxyl group of citric acid esterifies the hydroxyl groups in the wood components, along with internal rearrangements of lignin, resulting in improved physical properties [51]. The vegetable oils offer a wide range of possibilities for chemical transformations. After epoxidation, the epoxy groups in vegetable oils can react with acids, acid anhydrides, amines, polyols, and similar compounds [52]. Liu et al. [53] studied the use of furfuryl alcohol (FA) and epoxidized soybean oil (ESO) to modify radiata pine wood, achieving exceptional chemical structural performance and mechanical properties. This enhancement is attributed to the high molecular weight of ESO, its excellent hydrophobicity, and favorable intermolecular interactions between ESO and FA resin chains. The hydrophobic FA resin, along with FA-ESO thermosets, effectively filled the cell walls and lumens of the wood to improve its dimensional stability. When wood is used outdoors or as a structural component with exceptional strength properties, its mechanical properties and dimensional stability are crucial factors for performance improvement [54].

Wood used in the built environment requires special attention to its flame retardancy, as the combustion of wood can lead to fires that pose significant risks [55]. Sangregorio et al. [56] introduced an innovative wood modification process using humins, which are polydisperse furanic macromolecules formed during sugar dehydration. The humin modified wood exhibited enhanced hydrophobicity, with a lower mass increase and similar dimensional stability when immersed in water compared to furfurylated wood. Additionally, humin treated wood demonstrated longer ignition times, a slower heat release rate (−13%), and lower CO formation than furfurylated wood. Liu et al. [57] reported the preparation of flame-retardant wood using a novel biomass-based flame retardant via ultrasonic impregnation. This material shows excellent flame retardancy due to the release of non-combustible gases and the formation of a dense crosslinked carbon layer containing N=C, N-C/P-N, N-H, and C-O-P bonds.

Untreated or inadequately treated wood is susceptible to mold, fungal issues, and insect infestations, necessitating the use of economical biocides for interior applications. These biocides must be non-toxic, non-volatile, environmentally acceptable, safe for handling, and exhibit low solubility [58]. Pizzi et al. [59,60] have proposed that copper soaps derived from carboxylic acid groups in unsaturated fatty acids of edible vegetable oils which are non-toxic, resin acids from rosin, and even synthetic unsaturated polyester resins can serve as effective and durable groundcontact wood preservatives. Copper salts of unsaturated fatty acids based on sunflower oil and PCP esters of rosin have undergone field tests for fungal and termite resistance for 25 and 40 years, respectively, demonstrating high efficacy in wood preservation. Additionally, Conradie et al. [61] noted that in wood protection against fungi and termites, a waterborne dual treatment of DNBP (2-sec-butyl-4,6-dinitrobutylphenol) [dinitrobutylphenol] + NH3 on Pinus patula specimens is of commercial interest. This treatment involves a simple dip-diffusion method, followed by acetic acid or CuSO4, although the economic benefits are limited. A more economical approach is a single treatment with emulsified waterborne DNBP.

Additionally, a novel type of polyamide resin was developed by modifying microcrystalline cellulose. This resin features a hyperbranched crosslinked network structure, which imparts exceptional properties to the resultant plywood [62]. In a separate study, wood samples were coated with a hybrid nanocomposite consisting of polydopamine, hydroxyapatite, and chitosan, and their biodegradability in a marine environment was assessed. The chitosan used was derived from shrimp waste. Both control and treated wood samples were submerged in seawater for six months. The results indicated that the control wood exhibited more pronounced color changes, increased swelling, and a higher degree of barnacle infestation compared to the treated wood. Furthermore, analyses using FT-IR and XRD revealed that the structural integrity of lignin, cellulose, and hemicelluloses in the control wood was more significantly compromised than in the treated wood after immersion in seawater [63].

3 Nanotechnology for Wood Protection

Nanotechnology plays a pivotal role in the wood industry [64]. The integration of nanomaterials into wood enhances various properties while providing protection against fire, degradation, and biological decay [65]. According to Papadopoulos et al. [66], there are three primary methodologies for applying nanomaterials to wood: (i) immersing nanosized materials directly into the wood (e.g., nanosized metals), (ii) regulating the release of nanomaterials that are embedded within polymer nanomaterials, and (iii) applying a coating treatment.

Over the past decade, the application of metallic nanocompounds for the protection of wooden structures has concentrated on mitigating biodegradation and enhancing the durability of surface treatments [67]. Various forms of metal nanoparticles, including silver nanoparticles (Ag NPs) and copper nanoparticles (Cu NPs), as well as nanometal oxides such as zinc oxide nanoparticles (ZnO NPs) and aluminum oxide nanoparticles (Al2O3 NPs), along with nano metal fluorides like magnesium fluoride nanoparticles (MgF2 NPs) and calcium fluoride nanoparticles (CaF2 NPs), have gained prominence in wood preservation efforts [68–72].

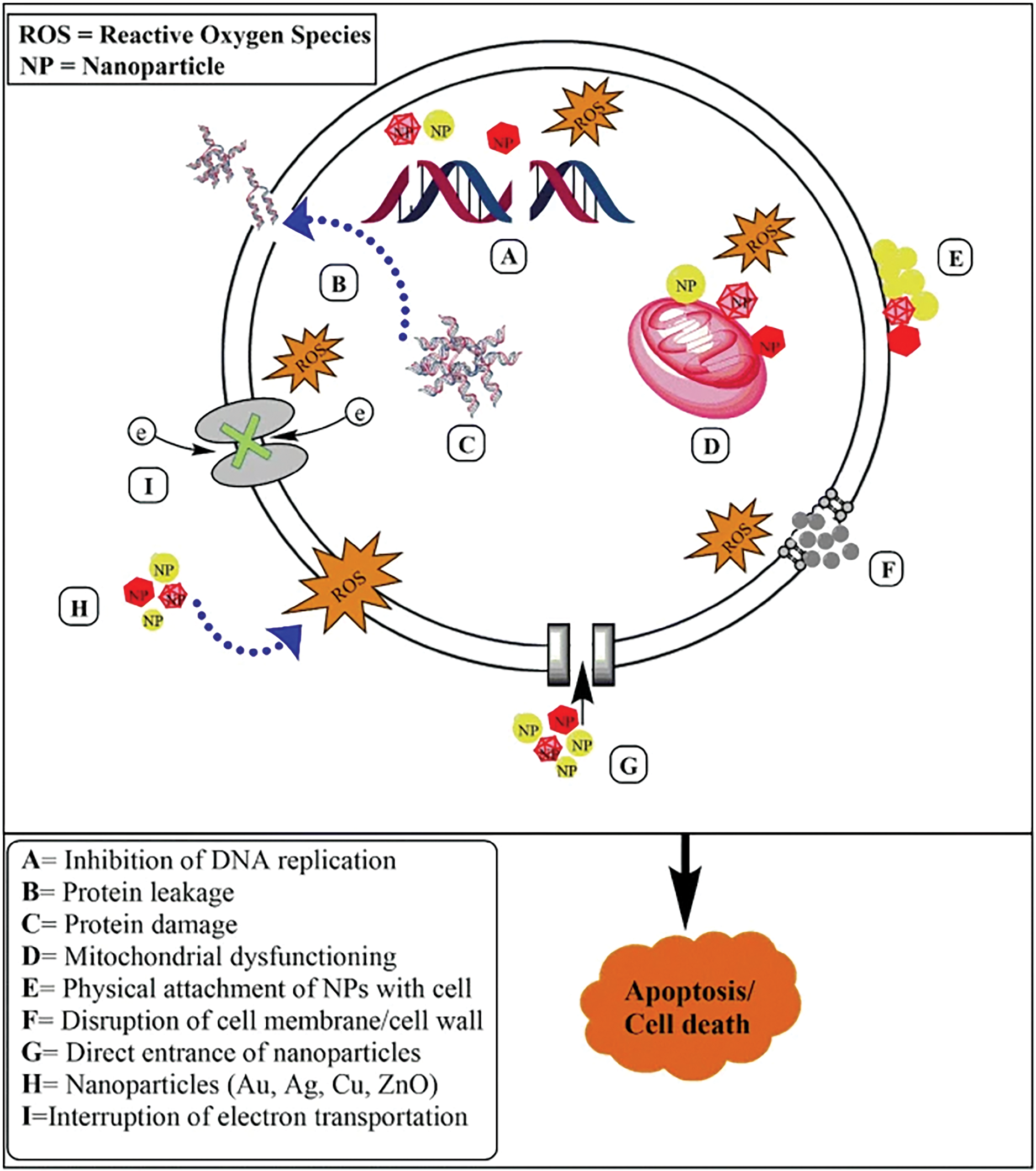

The potential mechanisms by which these metal-containing nanoparticles inhibit microbial growth are illustrated in Fig. 4: (a) excessive generation of reactive oxygen species (ROS) within microorganisms; (b) interference with critical enzymes in the respiratory chain due to disruption of the microbial plasma membrane; (c) accumulation of metal ions within microbial membranes; (d) electrostatic attraction to microbial cells, impairing metabolic functions; and (e) inhibition of microbial proteins and enzymes through enhanced production of H2O2 [73].

Figure 4: Illustration of possible antibacterial mechanism of action of biosynthesized metal nanoparticles. Adapted with permission from Reference [73]. Copyright ©2019, Springer Nature publishing

Numerous investigations have been conducted on the application of metal nanoparticles in wood treatments. Casado-Sanz et al. [74] employed a vacuum-pressure method within an autoclave to impregnate wood blocks with silver nanoparticles. Their results demonstrated that treatment with silver nanoparticles at concentrations ranging from 5 to 20 ppm exhibited significant antifungal properties, effectively protecting wood against fungal infestations.

Nano metal oxides are frequently applied to wood in conjunction with other materials, often using vacuum or pressure techniques. Reinprecht et al. [75] implemented an immersion method to introduce biologically active nano-ZnO into beech wood within a water system, at concentrations ranging from 0.1 to 3.3 wt.%. This treatment significantly enhanced decay resistance against the brown-rot fungus Rhodonia placenta and the white-rot fungus Trametes versicolor. The corrosion resistance of beech wood was further improved by additional thermal modification at 190°C for two hours. Nano-alumina is commonly used to create hydrophobic surfaces on wood.

Considerable research has been conducted on the application of nano-metal fluorides in wood preservation. Usmani et al. [72] synthesized MgF2 and CaF2 nanoparticles using the sol-gel method, followed by drying the samples under pressure and immersing them in a vacuum chamber after diluting the sol with ethanol. The results indicated that wood treated with nano-metal fluorides exhibited significant inhibitory effects against the brown rot fungi Coniophora puteana (Cp) and Rhodonia placenta (Rp). Currently, nano-metal fluorides (e.g., NaF) is used in wood preservation, however, sodium fluoride and magnesium fluoride demonstrate significantly lower sensitivity to leaching compared to NaF, making them more environmentally friendly and sustainable alternatives for wood preservation [76].

Polymer nanocomposites are increasingly utilized in the wood preservation sector to enhance the efficacy of conventional preservatives [66]. These composites consist of a polymer (as a matrix) and nanomaterials (as nano fillers), offering a range of functionalities due to the synergistic combination of their distinct components [77,78]. The two constituents retain their unique properties within the composite structure, the substrate secures the nanofillers in place, providing structural support, while the nanofillers impart new chemical and physical properties to the substrate [79].

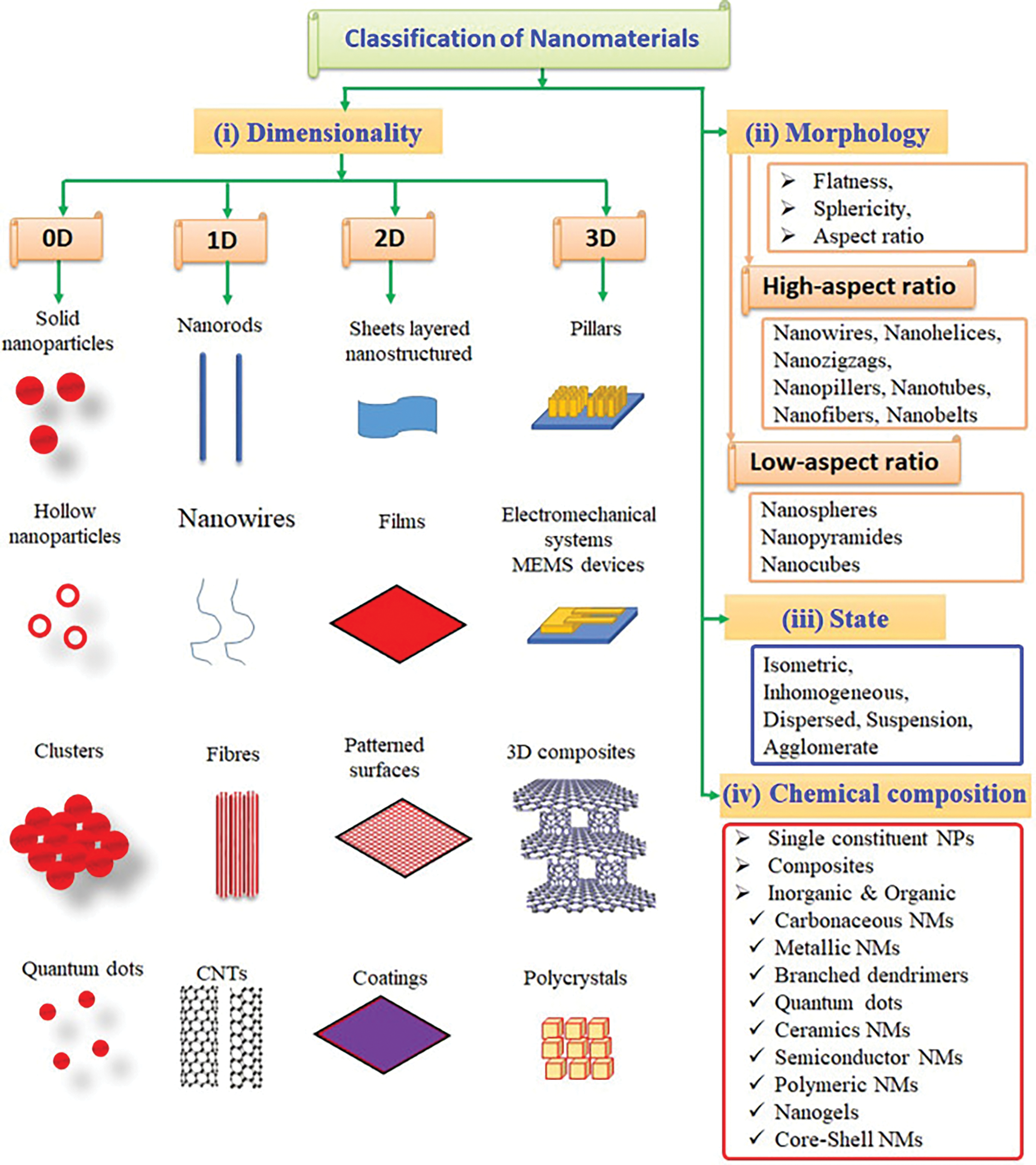

Nanomaterials (NMs) can be systematically classified into various categories based on several criteria. Typically, NMs are categorized according to their dimensionality, morphology, state, and chemical composition. Their size, which ranging from 1 to 100 nm in at least one dimension (Fig. 5) [80], is a key factor influencing the classification. NMs can be delineated as zero-dimensional (0D), one-dimensional (1D), two-dimensional (2D), and three-dimensional (3D) based on their dimensional characteristics [81]. 0D nanomaterials include spherical nanoparticles composed of metals, metal oxides, and quantum dots. 1D nanomaterials consist of carbon nanofibers, carbon nanotubes, and nanowhiskers, among others. Nanoclays and graphene-based materials are the most extensively researched 2D nanomaterials [82–85]. A notable feature of 3D nanomaterials is their porous structure, which imparts high electrical conductivity [86]. However, there is a lack of reports concerning the application of polymers incorporating 3D nanomaterials for wood mildew prevention.

Figure 5: Schematic illustration of the classification of nanomaterials based on different criteria. Adapted with permission from Reference [80]. Copyright ©2020, Elsevie Ltd. publishing

Four prevalent techniques for synthesizing polymer nanocomposites include: (i) extrusion or melt blending, (ii) solution pouring, (iii) in-situ polymerization, and (iv) layer-by-layer (LbL) deposition [87]. These techniques typically involve assembling the nanocomposites onto the wood surface in a layer-by-layer manner for thin-film deposition [88].

Zero-dimensional polymer nanomaterials are frequently employed in wood treatment applications. Harandi et al. [89] evaluated the antifungal properties of TiO2 and ZnO nanoparticles against the white rot fungus (Trametes versicolor) within a polyvinyl butyral (PVB). Poplar wood was treated with a nanocomposite under vacuum conditions as the raw material. The results indicated that samples treated with 1% nano-TiO2 and nano-ZnO dispersed in 5% PVB exhibited significant antifungal activity under light exposure. Moreover, samples containing 2% nanoparticles demonstrated antifungal effects even in the dark, with enhanced performance when exposed to light.

The utilization of 1D and 2D polymer nanomaterials in wood conservation is comparatively less explored than that of 0D polymer nanomaterials. Žigon et al. [90] proposed an innovative composite of poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP)/polyvinylpyrrolidone (PVP), incorporating MoO3 nanowires, which are capable of forming protective coatings on wood surfaces. The inclusion of MoO3 in the coating enhances the hydrophobicity of the wood and plays a crucial role in its resistance to blue-stain fungi and mold development. Hazarika et al. [91] developed a wood polymer nanocomposite (WPNC) consisting of multiwalled carbon nanotubes (MWCNTs) and nanoclay, which was impregnated using melamine formaldehyde furfuryl alcohol copolymer and 1,3-dimethylol-4,5-dihydroxy ethylene urea as a crosslinking agent. The resulting WPNC exhibited significant improvements in tensile, flexural, hardness, and water-resistant properties.

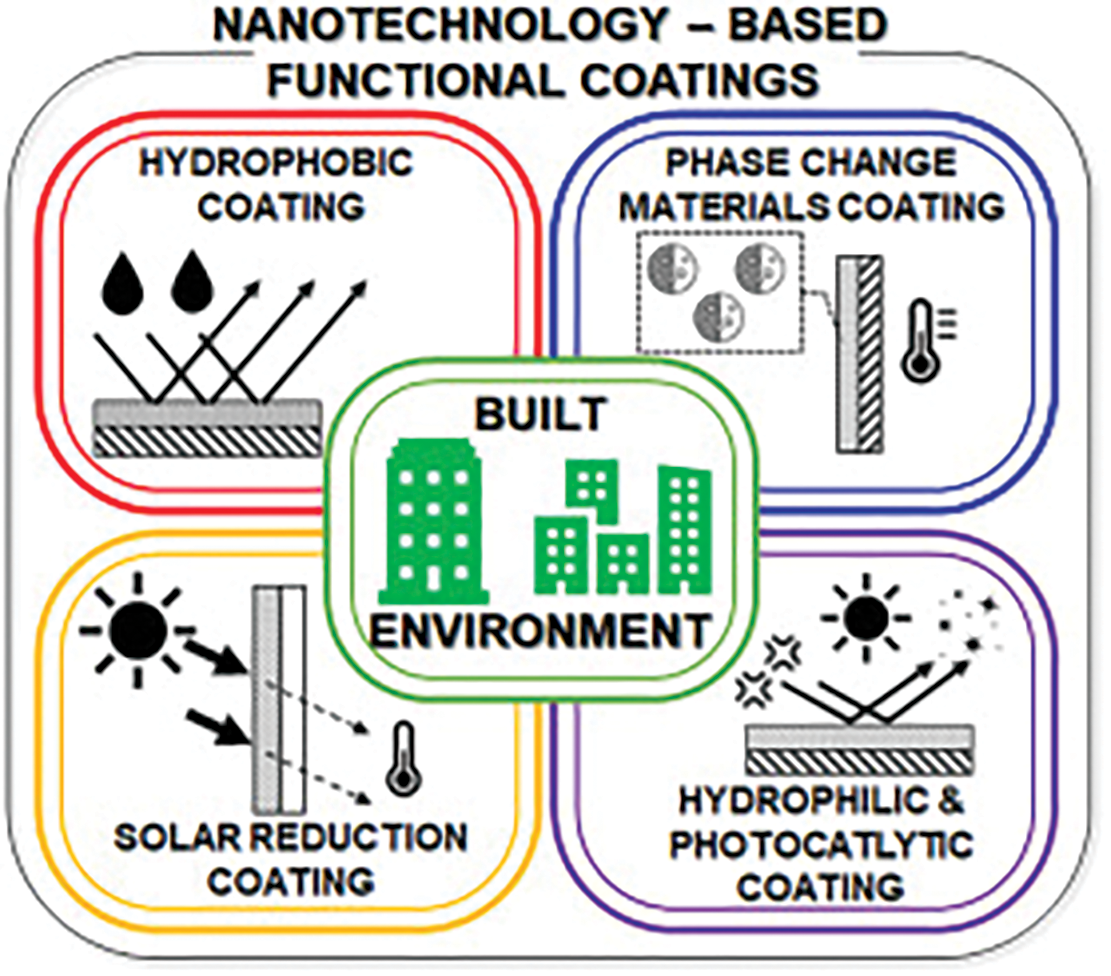

Coating materials are typically applied as outer layers to protect, enhance, and/or impart additional functionality and characteristics to the surface of the underlying object or bulk material. These coatings include hydrophobic coatings, phase change material (PCM) coatings, coatings designed to reduce surface solar radiation, as well as hydrophilic and photocatalytic coatings, all of which have been utilized in green and smart buildings (Fig. 6) [92]. Traditional wood coatings provide passive protection by forming a barrier that insulates the wood from environmental factors such as UV radiation, fluctuations in temperature and humidity, and attacks from insects, fungi, and mildew [93]. In contrast, smart coatings merit attention due to their capacity to dynamically respond to external stimuli. These coatings can adjust their properties in response to a variety of external factors, including but not limited to pH levels, light, electric and magnetic fields, pressure, and temperature [94,95].

Figure 6: Nanotechnology-based functional coatings. Adapted with permission from Reference [92]. Copyright ©2022, Elsevie Ltd. publishing

The advancement of nanotechnology has significantly enhanced the field of coatings. A wide range of nanomaterials has been incorporated into coating formulations, enabling the development of superhydrophobic coatings with diverse functionalities, such as anti-corrosion, anti-icing, and anti-fogging properties [96,97]. Methods for achieving superhydrophobic surfaces include sol-gel processes, chemical etching, dip-coating, and chemical deposition. Additionally, surface roughness can be enhanced through physical etching and electrochemical deposition, providing an alternative approach to creating superhydrophobic surfaces [98].

Wang et al. [99] synthesized nano silica coatings on wood surfaces using the sol-gel process and subsequently fluorinated these coatings with the surface modifying agent 1H, 1H, 2H, 2H-perfluoroalkyltriethoxysilanes (POTS). The combination of the high surface roughness of the nano silica coatings and the low surface free energy of the POTS film resulted in a superhydrophobic wood surface. Tuong et al. [100] applied epoxy@ZnO superhydrophobic paint to Styrax tonkinensis wood using a two-step spraying technique. The hydrophobicity of the wood was significantly enhanced after the coating, and its color stability was notably improved. Duan et al. [101] produced wood veneer exhibiting both superhydrophobic and antibacterial properties through self-polymerization of dopamine, chemical deposition of Cu nanoparticles, and hydrophobic modification with fluorosilane. These superhydrophobic surfaces demonstrated excellent stability under various harsh conditions, including strong acids/bases, high temperature aging, and mechanical wear. In addition, they exhibited remarkable self-cleaning and antibacterial properties.

A superhydrophobic chitosan/silica hybrid nanocomposite was used as a coating for wood. After applying the coating, both the coated and control wood samples were exposed to a corrosive seawater environment for six months. The results showed that the coated wood exhibited significantly reduced weathering and erosion compared to the control wood. Furthermore, analyses using FESEM and XRD revealed that the coated wood experienced considerably less degradation after immersion in seawater than the control samples [102].

Currently, there is no definitive classification for smart coatings, as they often combine various types of functionalities. A smart coating can be designed as either a single-layer or multi-layer system, consisting of at least two layers [103]. El-Naggar et al. [104] developed a smart photoluminescent nanocomposite surface coating for wood substrates that emits light continuously in darkness for up to 1.5 h. Lanthanide-doped aluminium strontium oxide (LASO) nanoparticles were incorporated into polystyrene (PS) in varying proportions to create a nanocomposite coating on wooden surfaces. The wood coated with the LASO-PS nanocomposite film exhibited superhydrophilicity, light stability, and photostability. This innovative coating has potential applications in safety directional signs, household products, and smart windows.

4 Quaternary Ammonium Compound Bound Nanoparticles

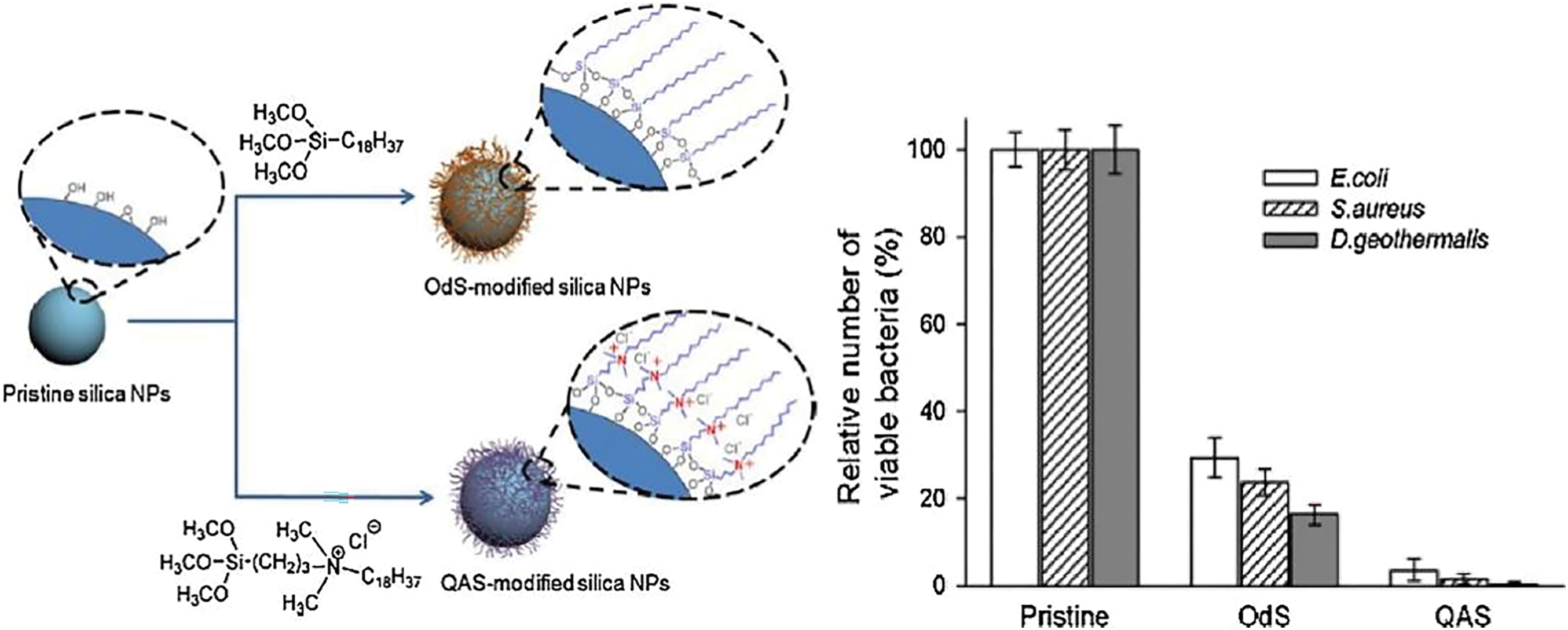

Quaternary ammonium compounds (QACs) are a primary class of cationic surfactants, characterized by a positively charged nitrogen atom attached to at least one hydrophobic hydrocarbon chain, typically composed of short chain substituents such as methyl or benzyl groups [105,106]. QACs are mild disinfectants known for their high efficacy and broad spectrum biological activity against viruses, bacteria, and parasites [107,108]. Song et al. [109] synthesized silica NPs covalently bonded with trimethoxysilyl-propyldimethyloctadecyl ammonium chloride (QAC), alongside silica NPs modified with octadecyltrimethoxy silane (OdS) without QAC. The silica QAC core-shell NPs exhibited stronger inhibitory activity against the growth of Escherichia coli, Staphylococcus aureus, and Deinococcus geothermalis compared to the original and OdS modified silica NPs (Fig. 7).

Figure 7: (left) Schematic illustrations of the preparation of silane-modified silica NPs and chemical structures of silane agents. (right) Relative number of viable bacteria on glass slides coated with pristine, OdS-modified, and QAC-modified silica NPs. The relative number of each species of bacteria adhered on the pristine silica NPs coated glass surface was defined as 100%. Adapted with permission from References [109,110]. Copyright ©2011, Elsevie Ltd. publishing and 2018, Elsevie Ltd. publishing

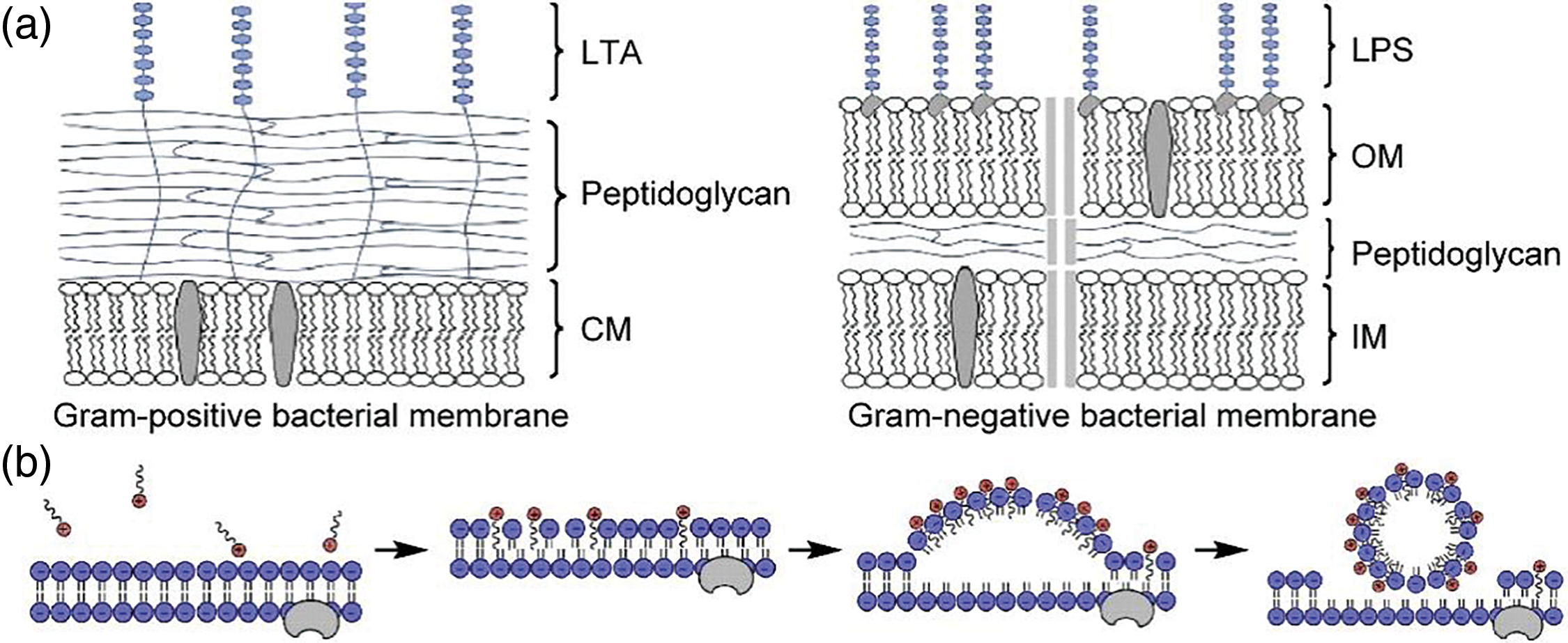

Based on spatial dimensions and the interaction processes between QACs and bacteria, the antibacterial mechanisms of QACs primarily target biofilms, cell membranes, and intracellular components. When QACs disrupt bacterial cell membranes, both Gram-positive and Gram-negative bacteria exhibit amphiphilic and anionic characteristics due to the presence of key components like lipoteichoic acid and lipopolysaccharide (Fig. 8a). Initially, QACs interact with the bacterial surface through electrostatic interactions before traversing the cell wall. This process is further facilitated by the affinity of the hydrophobic structures for the membrane. The nonpolar tail of the QACs inserts into the bacterial cell membrane, promoting pore formation that compromises cellular integrity, ultimately leading to bacterial death (Fig. 8b). The cell membrane is a critical target for QACs as antibacterial agents. The positively charged quaternary nitrogen in QACs interacts with the negatively charged head groups of acidic phospholipids within the cell membrane, enabling translocation across the membrane and compromising cellular integrity, which results in bacterial death [110–112]. The antibacterial efficacy of QACs is influenced by the alkyl chain length. Specifically, quaternary ammonium groups containing ten or more carbon atoms exhibit enhanced bactericidal activity. However, excessively long alkyl chains may induce significant aggregation among the polymers, thereby reducing their biocidal effectiveness [113].

Figure 8: (a) Components of bacterial membrane. lipoteichoic acids (LTA), cytoplasmic plasma membrane (CM), lipopolysaccharides (LPS), outer membrane (OM), inner membrane (IM); (b) Membrane-active mechanism of QACs. Adapted with permission from Refs. [111,112,114]. Copyright ©2022, Elsevie Ltd. publishing, 2021, John Wiley & Sons publishing and 2019, Elsevie Ltd. publishing

QACs can be employed to coat substrate surfaces, thereby imparting antibacterial properties to the substrates. Saif et al. [115] developed a hybrid coating on glass surfaces using the sol-gel process with Q4N+-Si(OR)S to evaluate its efficacy against Escherichia coli and Staphylococcus aureus. A significant correlation was observed between the concentration of Q4N+-Si(OR)S and its antibacterial activity.

The size of quaternary ammonium nanoparticles is closely correlated with their antimicrobial activity, with smaller nanoparticles demonstrating superior effectiveness [112]. When covalently bonded to the surface of wood materials, QACs enable the wood to resist microbial invasion [103]. A more prevalent application of QACs as surface antimicrobials involves their combination with nanoscale materials to interact with wood substrate surfaces. Wang et al. [116] designed and synthesized a pH-responsive preservative delivery system for bio-based wood preservation. In this system, QACs were encapsulated within hollow mesoporous organic silica nanoparticles (HMONs), while carbon quantum dots (CQDs) acted as mesoporous plugging agents. The QACs-HMON-CQD exhibited exceptional antifungal properties. Furthermore, an environmentally friendly wood preservative was developed, characterized by excellent antibacterial effects and low toxicity. Nitrogen-doped carbon quantum dots (N-CQDs) were synthesized through a one-step hydrothermal method using chitosan quaternary ammonium salt (HACC) as the precursor material. The decay rate of wood treated with N-CQDs was significantly reduced, enhancing both its utilization and service life [117].

Currently, the predominant coatings applied to wood surfaces are polyurethane, which inherently lacks antimicrobial properties [118]. The incorporation of QACs enhances the antimicrobial efficacy of these polyurethane coatings [113]. Furthermore, the synergistic interaction between QACs and nanoparticles can yield polyurethane coatings with significant antibacterial effects. These coatings can be synthesized through various methodologies and employed in diverse applications. Tominaga et al. [119] reported an antibacterial photocurable acrylic resin coating based on silver nanoclusters (Ag NCs), formulated by integrating conjugates of dihydrolipoic acid-capped ligand-protected Ag NCs with tetraoctylammonium (TOA), referred to as TOA-Ag NCs. This antibacterial resin demonstrated effective bactericidal activity due to the dual action of Ag NCs and TOA, maintaining its efficacy over extended periods even when exposed to aqueous environments. Mathew et al. [120] successfully adsorbed a silyl-anchoring quaternary ammonium salt (AQAS) with a long alkyl chain (C18) onto the surface of a flexible, thermoset transparent polyurethane (PUR) film from an aqueous solution, followed by solidification at 160°C to produce PUR-AQAS films. These films used as substrates for anchoring antibacterial molecular layers and exhibited substantial potency, achieving a 3-log reduction against Staphylococcus aureus and Escherichia coli. Such polyurethane coatings are typically sprayed or brushed onto wood surfaces to safeguard them from potential damage.

This paper reviews the application of nanotechnology in wood preservation. As a bio-based material, wood is vulnerable to mold growth and decay caused by wood-destroying fungi, which can result in surface discoloration and structural degradation. To address these challenges while considering the inherent properties of wood, nanomaterials are employed through three primary approaches: (i) nanosized metals, (ii) polymer nanocomposites, and (iii) coating treatments. These methods enhance the chemical properties of the wood surface or provide protective coatings that improve resistance against mold and rot-inducing fungi. Compared to traditional preservation techniques, the use of nanomaterials offers greater environmental compatibility while extending the service life of wood and enhancing its value. This paper introduces recent advancements in the categorization and application of various nanomaterials aimed at preventing microbial degradation in wood, offering innovative strategies for developing efficient, safe, and sustainable wood protection solutions.

Current nanotechnology applications in wood protection primarily focus on minimizing the interaction between wood and external environmental factors, such as water and microorganisms. While this approach does not pose particularly high technological challenges, microbes continue to persist on the wood surface and accumulate over time. Therefore, it is crucial to enhance the approach by actively eliminating microorganisms in addition to reducing their contact with the wood. Over time, as the need for prolonged efficacy increases, the technical requirements become more demanding, making practical implementation more complex. In the long term, combining both strategies—reducing exposure to external elements and actively eliminating microorganisms—will provide a more sustainable and effective approach to wood protection, representing a promising direction for future research.

Acknowledgement: The authors thank every author for their valuable suggestions, contribution and the fund for its support.

Funding Statement: This research was sponsored by Key Lab. of Biomass Energy and Material, Jiangsu Province (JSBEM-S-202305) and Guangdong Academy of Forestry (2022-GDFS-KJ-03).

Author Contributions: The authors confirm contribution to the paper as follows: data collection and draft manuscript preparation: Yuxin He, Yixin Li; study conception and design: Qiaoguang Li, Wenqing Xiao, Guijun Xie. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data that support the findings of this study are available from the corresponding author upon reasonable request.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Wang J, Simson R, Gleisner R, Fishwild SJ, Begel M, Zhu JY. Carbonate pre-treatment of wood for transformative structural applications through densification. Ind Crops Prod. 2022;188:115645. doi:10.1016/j.indcrop.2022.115645. [Google Scholar] [CrossRef]

2. Zelinka SL, Altgen M, Emmerich L, Guigo N, Keplinger T, Kymäläinen M, et al. Review of wood modification and wood functionalization technologies. Forests. 2022;13(7):1004. doi:10.3390/f13071004. [Google Scholar] [CrossRef]

3. Jiang F, Li T, Li Y, Zhang Y, Gong A, Dai J, et al. Wood-based nanotechnologies toward sustainability. Adv Mater. 2018;30(1):1703453. doi:10.1002/adma.201703453. [Google Scholar] [PubMed] [CrossRef]

4. Zhu H, Luo W, Ciesielski PN, Fang Z, Zhu JY, Henriksson G, et al. Wood-derived materials for green electronics, biological devices, and energy applications. Chem Rev. 2016;116(16):9305–74. doi:10.1021/acs.chemrev.6b00225. [Google Scholar] [PubMed] [CrossRef]

5. Zuo Y, Feng J, Soyol-Erdene TO, Wei Z, Hu T, Zhang Y, et al. Recent advances in wood-derived monolithic carbon materials: synthesis approaches, modification methods and environmental applications. Chem Eng J. 2023;463:142332. doi:10.1016/j.cej.2023.142332. [Google Scholar] [CrossRef]

6. Ramage MH, Burridge H, Busse-Wicher M, Fereday G, Reynolds T, Shah DU, et al. The wood from the trees: the use of timber in construction. Renew Sustain Energ Rev. 2017;68:333–59. doi:10.1016/j.rser.2016.09.107. [Google Scholar] [CrossRef]

7. Zhang Y, Chen X, Wu Y, Shuai C, Shen L. The environmental Kuznets curve of CO2 emissions in the manufacturing and construction industries: a global empirical analysis. Environ Impact Assess Rev. 2019;79:106303. doi:10.1016/j.eiar.2019.106303. [Google Scholar] [CrossRef]

8. Švajlenka J, Pošiváková T. Innovation potential of wood constructions in the context of sustainability and efficiency of the construction industry. J Clean Prod. 2023;411:137209. doi:10.1016/j.jclepro.2023.137209. [Google Scholar] [CrossRef]

9. Salem MZM, Zidan YE, Mansour MMA, El Hadidi NMN, Abo Elgat WAA. Antifungal activities of two essential oils used in the treatment of three commercial woods deteriorated by five common mould fungi. Int Biodeterior Biodegrad. 2016;106:88–96. doi:10.1016/j.ibiod.2015.10.010. [Google Scholar] [CrossRef]

10. Ren Z, Sun H, Zhou X, Chi X, Bi H, Ji T, et al. Insights from molecular dynamics simulations for interfacial effects between polylactic acid and wood cell wall constituents. Composit Part A: Appl Sci Manufact. 2023;164:107310. doi:10.1016/j.compositesa.2022.107310. [Google Scholar] [CrossRef]

11. Arzola-Villegas X, Lakes R, Plaza NZ, Jakes JE. Wood moisture-induced swelling at the cellular scale—ab intra. Forests. 2019;10(11):996. doi:10.3390/f10110996. [Google Scholar] [CrossRef]

12. Ayanleye S, Udele K, Nasir V, Zhang X, Militz H. Durability and protection of mass timber structures: a review. J Build Eng. 2022;46:103731. doi:10.1016/j.jobe.2021.103731. [Google Scholar] [CrossRef]

13. Gobakken LR, Høibø OA, Solheim H. Mould growth on paints with different surface structures when applied on wooden claddings exposed outdoors. Int Biodeterior Biodegrad. 2010;64(5):339–45. doi:10.1016/j.ibiod.2009.11.005. [Google Scholar] [CrossRef]

14. Brambilla A, Sangiorgio A. 4-Health and mould growth. In: Brambilla A, Sangiorgio A, editors. Moisture and buildings. Woodhead publishing series in civil and structural engineering. Woodhead Publishing; 2021. p. 63–98. doi:10.1016/B978-0-12-821097-0.00004-7. [Google Scholar] [CrossRef]

15. Kuka E, Cirule D, Andersone I, Andersons B, Fridrihsone V. Conditions influencing mould growth for effective prevention of wood deterioration indoors. Appl Sci. 2022;12(3):975. doi:10.3390/app12030975. [Google Scholar] [CrossRef]

16. Salem MZM. EDX measurements and SEM examination of surface of some imported woods inoculated by three mould fungi. Measurement. 2016;86:301–9. doi:10.1016/j.measurement.2016.03.008. [Google Scholar] [CrossRef]

17. Pfeffer A, Hoegger PJ, Kües U, Militz H. Fungal colonisation of outside weathered modified wood. Wood Sci Technol. 2012;46(1):63–72. doi:10.1016/j.heliyon.2023.e17355. [Google Scholar] [PubMed] [CrossRef]

18. Daniel G. Chapter 8-fungal degradation of wood cell walls. In: Kim YS, Funada R, Singh AP, editors. Secondary xylem biology. Academic Press; 2016. p. 131–67. doi:10.1016/B978-0-12-802185-9.00008-5. [Google Scholar] [CrossRef]

19. Hobbie EA, Grandy AS, Harmon ME. Isotopic and compositional evidence for carbon and nitrogen dynamics during wood decomposition by saprotrophic fungi. Fungal Ecol. 2020;45:100915. doi:10.1016/j.funeco.2020.100915. [Google Scholar] [CrossRef]

20. Singh AP, Singh T. Biotechnological applications of wood-rotting fungi: a review. Biomass Bioene. 2014;62:198–206. doi:10.1016/j.biombioe.2013.12.013. [Google Scholar] [CrossRef]

21. Shilova OA, Tsvetkova IN, Vlasov DY, Ryabusheva YV, Sokolov GS, Kychkin AK, et al. 13-Microbiologically induced deterioration and environmentally friendly protection of wood products. In: Iqbal HMN, Bilal M, Nguyen TA, Yasin G, editors. Biodegradation and biodeterioration at the nanoscale. Micro and nano technologies. Elsevier; 2022. p. 283–321. doi:10.1016/B978-0-12-823970-4.00013-0. [Google Scholar] [CrossRef]

22. Donmez Cavdar A. Effect of various wood preservatives on limiting oxygen index levels of fir wood. Measurement. 2014;50:279–84. doi:10.1016/j.measurement.2014.01.009. [Google Scholar] [CrossRef]

23. Barbero-López A, Akkanen J, Lappalainen R, Peräniemi S, Haapala A. Bio-based wood preservatives: their efficiency, leaching and ecotoxicity compared to a commercial wood preservative. Sci Total Environ. 2021;753:142013. doi:10.1016/j.scitotenv.2020.142013. [Google Scholar] [PubMed] [CrossRef]

24. Xia Y, Ma C, Wang H, Sun S, Wen J, Sun R. Multiple analysis and characterization of novel and environmentally friendly feather protein-based wood preservatives. Polymers. 2020;12(1):237. doi:10.3390/polym12010237. [Google Scholar] [PubMed] [CrossRef]

25. Janin A, Coudert L, Riche P, Mercier G, Cooper P, Blais JF. Application of a CCA-treated wood waste decontamination process to other copper-based preservative-treated wood after disposal. J Hazard Mater. 2011;186(2):1880–7. doi:10.1016/j.jhazmat.2010.12.094. [Google Scholar] [PubMed] [CrossRef]

26. Tascioglu C, Tsunoda K. Laboratory evaluation of wood-based composites treated with alkaline copper quat against fungal and termite attacks. Int Biodeterior Biodegrad. 2010;64(8):683–7. doi:10.1016/j.ibiod.2010.05.010. [Google Scholar] [CrossRef]

27. Hasan AR, Hu L, Solo-Gabriele HM, Fieber L, Cai Y, Townsend TG. Field-scale leaching of arsenic, chromium and copper from weathered treated wood. Environ Pollut. 2010;158(5):1479–86. doi:10.1016/j.envpol.2009.12.027. [Google Scholar] [PubMed] [CrossRef]

28. Kim JY, Oh S, Park YK. Overview of biochar production from preservative-treated wood with detailed analysis of biochar characteristics, heavy metals behaviors, and their ecotoxicity. J Hazard Mater. 2020;384:121356. doi:10.1016/j.jhazmat.2019.121356. [Google Scholar] [PubMed] [CrossRef]

29. Lin LD, Chen YF, Wang SY, Tsai MJ. Leachability, metal corrosion, and termite resistance of wood treated with copper-based preservative. Int Biodeterior Biodegrad. 2009;63(4):533–8. doi:10.1016/j.ibiod.2008.07.012. [Google Scholar] [CrossRef]

30. Civardi C, Grolimund D, Schubert M, Wick P, Schwarze FWMR. Micronized copper-treated wood: copper remobilization into spores from the copper-tolerant wood-destroying fungus Rhodonia placenta. Environ Sci: Nano. 2019;6(2):425–31. doi:10.1039/C8EN01110A. [Google Scholar] [CrossRef]

31. Johnson MG, Luxton TP, Rygiewicz PT, Reichman JR, Bollman MA, King GA, et al. Transformation and release of micronized Cu used as a wood preservative in treated wood in wetland soil. Environ Pollut. 2021;287:117189. doi:10.1016/j.envpol.2021.117189. [Google Scholar] [PubMed] [CrossRef]

32. Shukla SR, Kamdem DP. Effect of micronized copper treatments on retention, strength properties, copper leaching and decay resistance of plantation grown Melia dubia Cav. wood. Eur J Wood Prod. 2023;81(2):513–28. doi:10.1007/s00107-022-01889-1. [Google Scholar] [CrossRef]

33. Fredriksson M, Rüggeberg M, Nord-Larsen T, Beck G, Thybring EE. Water sorption in wood cell walls-data exploration of the influential physicochemical characteristics. Cellulose. 2023;30(3):1857–71. doi:10.1007/s10570-022-04973-0. [Google Scholar] [CrossRef]

34. Yang T, Thybring EE, Fredriksson M, Ma E, Cao J, Digaitis R, et al. Effects of changes in biopolymer composition on moisture in acetylated wood. Forests. 2020;11(7):719. doi:10.3390/f11070719. [Google Scholar] [CrossRef]

35. Schwarzinger C, List M. Identification of marker compounds in pyrolysis-GC/MS of various acetylated wood types. J Anal Appl Pyrolysis. 2010;87(1):144–53. doi:10.1016/j.jaap.2009.11.001. [Google Scholar] [CrossRef]

36. Hill C, Altgen M, Rautkari L. Thermal modification of wood—a review: chemical changes and hygroscopicity. J Mater Sci. 2021;56(11):6581–614. doi:10.1007/s10853-020-05722-z. [Google Scholar] [CrossRef]

37. Bi Z, Morrell JJ, Lei Y, Yan L, Ji M. Eco-friendly and mildly modification of wood cell walls with heat treated wood extracts to improve wood decay resistance. Ind Crops Prod. 2022;184(13):115079. doi:10.1016/j.indcrop.2022.115079. [Google Scholar] [CrossRef]

38. Hoseinzadeh F, Zabihzadeh SM, Dastoorian F. Creep behavior of heat treated beech wood and the relation to its chemical structure. Constr Build Mater. 2019;226:220–6. doi:10.1016/j.conbuildmat.2019.07.181. [Google Scholar] [CrossRef]

39. Jang ES, Kang CW. Changes in gas permeability and pore structure of wood under heat treating temperature conditions. J Wood Sci. 2019;65(1):37. doi:10.1186/s10086-019-1815-3. [Google Scholar] [CrossRef]

40. Zhang X, Song S, Li X, Zhu Y, Li X, Xu K, et al. Effect of low molecular weight melamine-urea-formaldehyde resin impregnation on poplar wood pore size distribution and water sorption. Ind Crops Prod. 2022;188:115700. doi:10.1016/j.indcrop.2022.115700. [Google Scholar] [CrossRef]

41. Łukawski D, Lekawa-Raus A, Lisiecki F, Koziol K, Dudkowiak A. Towards the development of superhydrophobic carbon nanomaterial coatings on wood. Prog Org Coat. 2018;125:23–31. doi:10.1016/j.porgcoat.2018.08.025. [Google Scholar] [CrossRef]

42. Athulya R, Nandini J, Bhoi TK, Sundararaj R. Recent advances of nanotechnology in wood protection: a comprehensive review. Wood Mat Sci Eng. 2024;19(2):279–90. doi:10.1080/17480272.2023.2239800. [Google Scholar] [CrossRef]

43. Bansal R, Barshilia HC, Pandey KK. Nanotechnology in wood science: innovations and applications. Int J Biol Macromol. 2024;262:130025. doi:10.1016/j.ijbiomac.2024.130025. [Google Scholar] [PubMed] [CrossRef]

44. Montanari C, Olsén P, Berglund LA. Sustainable wood nanotechnologies for wood composites processed by in-situ polymerization. Front Chem. 2021;9:682883. doi:10.3389/fchem.2021.682883. [Google Scholar] [PubMed] [CrossRef]

45. Zhao Y. Studies on pre-treatment by compression for wood drying III: the reduction of moisture content, the recovery rate, and mechanical properties of wood compressed at different moisture content conditions. J Wood Sci. 2017;63(3):209–15. doi:10.1007/s10086-017-1612-9. [Google Scholar] [CrossRef]

46. Weng Y. Preface for special issue on bio-based materials. Chin J Biotechnol. 2016;32(6):711–4. doi:10.13345/j.cjb.160192. [Google Scholar] [PubMed] [CrossRef]

47. Liu S, Zhu M, Huang Y, Yu Y, Yu W, Lv B. A nature-inspired strategy towards superhydrophobic wood. J Mater Chem A. 2023;11(47):25875–86. doi:10.1039/D3TA05013K. [Google Scholar] [CrossRef]

48. Yan W, Guan Q, Jin F. Catalytic conversion of cellulosic biomass to harvest high-valued organic acids. iScience. 2023;26(10):107933. doi:10.1016/j.isci.2023.107933. [Google Scholar] [PubMed] [CrossRef]

49. Kurkowiak K, Emmerich L, Militz H. Wood chemical modification based on bio-based polycarboxylic acid and polyols—status quo and future perspectives. Wood Mat Sci Eng. 2022;17(6):1040–54. doi:10.1080/17480272.2021.1925961. [Google Scholar] [CrossRef]

50. Berube MA, Schorr D, Ball RJ, Landry V, Blanchet P. Determination of in situ esterification parameters of citric acid-glycerol based polymers for wood impregnation. J Polym Environ. 2018;26(3):970–9. doi:10.1007/s10924-017-1011-8. [Google Scholar] [CrossRef]

51. Del Menezzi C, Amirou S, Pizzi A, Xi X, Delmotte L. Reactions with wood carbohydrates and lignin of citric acid as a bond promoter of wood veneer panels. Polymers. 2018;10(8):833. doi:10.3390/polym10080833. [Google Scholar] [PubMed] [CrossRef]

52. Rosu L, Varganici C, Mustata F, Rosu D, Rosca I, Rusu T. Epoxy coatings based on modified vegetable oils for wood surface protection against fungal degradation. ACS Appl Mater Interfaces. 2020;12(12):14443–58. doi:10.1021/acsami.0c00682. [Google Scholar] [PubMed] [CrossRef]

53. Liu M, Lyu S, Peng L, Cai L, Huang Z, Lyu J. Improvement of toughness and mechanical properties of furfurylated wood by biosourced epoxidized soybean oil. ACS Sustain Chem Eng. 2021;9(24):8142–55. doi:10.1021/acssuschemeng.1c01358. [Google Scholar] [CrossRef]

54. Li X, Qiang M, Yang M, Morrell JJ, Zhang N. Combining fiber enzymatic pretreatments and coupling agents to improve physical and mechanical properties of hemp hurd/wood/polypropylene composite. Materials. 2021;14(21):6384. doi:10.3390/ma14216384. [Google Scholar] [PubMed] [CrossRef]

55. Yona AMC, Žigon J, Matjaž P, Petrič M. Potentials of silicate-based formulations for wood protection and improvement of mechanical properties: a review. Wood Sci Technol. 2021;55(4):887–918. doi:10.1007/s00226-021-01290-w. [Google Scholar] [CrossRef]

56. Sangregorio A, Muralidhara A, Guigo N, Thygesen LG, Marlair G, Angelici C, et al. Humin based resin for wood modification and property improvement. Green Chem. 2020;22(9):2786–98. doi:10.1039/C9GC03620B. [Google Scholar] [CrossRef]

57. Liu B, Liu P, Ma Z, Chola M, Chen M, Guo H, et al. Chemical, pyrolysis, combustion properties and mechanism analysis of wood treated with biomass-based carrageenan-collagen modified ammonium polyphosphate. Surf Interfaces. 2024;46:104121. doi:10.1016/j.surfin.2024.104121. [Google Scholar] [CrossRef]

58. Clausen CA, Yang V. Protecting wood from mould, decay, and termites with multi-component biocide systems. Int Biodeterior Biodegrad. 2007;59(1):20–4. doi:10.1016/j.ibiod.2005.07.005. [Google Scholar] [CrossRef]

59. Pizzi A. A new approach to non-toxic, wide-spectrum, ground-contact wood preservatives. Part I. Approach and reaction mechanisms. Holzforschung. 1993;47(3):253–60. doi:10.1515/hfsg.1993.47.3.253. [Google Scholar] [CrossRef]

60. Pizzi A. A new approach to non-toxic, wide-spectrum, ground-contact wood preservatives. Part II. Accelerated and long-term field tests. Holzforschung. 1993;47(4):343–8. doi:10.1515/hfsg.1993.47.4.343. [Google Scholar] [CrossRef]

61. Conradie WE, Pizzi A. Waterborne DNBP wood preservtives-preparationand performance. Holzforschung und Holzverwertung. 1987;39(2):21–4. [Google Scholar]

62. Jin T, Zeng H, Huang Y, Liu L, Yao W, Guo H, et al. Synthesis of biomass hyperbranched polyamide resin from cellulose and citric acid for wood adhesive. Int J Biol Macromol. 2023;253:126575. doi:10.1016/j.ijbiomac.2023.126575. [Google Scholar] [PubMed] [CrossRef]

63. Esfandiar N, Elmi F, Omidzahir S. Study of the structural properties and degradation of coated wood with polydopamine/hydroxyapatite/chitosan hybrid nanocomposite in seawater. Cellulose. 2020;27(13):7779–90. doi:10.1007/s10570-020-03324-1. [Google Scholar] [CrossRef]

64. Kumar A, Nguyen TA, Sharma S, Bhat R. Chapter 1-Nanotechnology in paper and wood engineering: an introduction. In: Bhat R, Kumar A, Nguyen TA, Sharma S, editors. Nanotechnology in paper and wood engineering. Micro and nano technologies. Elsevier; 2022. p. 3–13. doi:10.1016/B978-0-323-85835-9.00015-5. [Google Scholar] [CrossRef]

65. Taghiyari HR, Tajvidi M, Taghiyari R, Mantanis GI, Esmailpour A, Hosseinpourpia R. Chapter 19-Nanotechnology for wood quality improvement and protection. In: Husen A, Jawaid M, editors. Nanomaterials for agriculture and forestry applications. Micro and nano technologies. Elsevier; 2020. p. 469–89. doi:10.1016/B978-0-12-817852-2.00019-6. [Google Scholar] [CrossRef]

66. Papadopoulos AN, Bikiaris DN, Mitropoulos AC, Kyzas GZ. Nanomaterials and chemical modifications for enhanced key wood properties: a review. Nanomaterials. 2019;9(4):607. doi:10.3390/nano9040607. [Google Scholar] [PubMed] [CrossRef]

67. Goffredo GB, Citterio B, Biavasco F, Stazi F, Barcelli S, Munafò P. Nanotechnology on wood: the effect of photocatalytic nanocoatings against Aspergillus niger. J Cult Herit. 2017;27:125–36. doi:10.1016/j.culher.2017.04.006. [Google Scholar] [CrossRef]

68. Aguayo MG, Oviedo C, Reyes L, Navarrete J, Gómez L, Torres H, et al. Radiata pine wood treated with copper nanoparticles: leaching analysis and fungal degradation. Forests. 2021;12(11):1606. doi:10.3390/f12111606. [Google Scholar] [CrossRef]

69. de Peres ML, de Delucis RA, Amico SC, Gatto DA. Zinc oxide nanoparticles from microwave-assisted solvothermal process: photocatalytic performance and use for wood protection against xylophagous fungus. Nanomater Nanotechnol. 2019;9. doi:10.1177/1847980419876201. [Google Scholar] [CrossRef]

70. Feng B, Zhang S, Wang D, Li Y, Zheng P, Gao L, et al. Study on antibacterial wood coatings with soybean protein isolate nano-silver hydrosol. Prog Org Coat. 2022;165:106766. doi:10.1016/j.porgcoat.2022.106766. [Google Scholar] [PubMed] [CrossRef]

71. Porwal P, Taghiyari HR, Husen A. Chapter 20-Use of nanomaterials in the forest industry. In: Husen A, Siddiqi KS, editors. Advances in smart nanomaterials and their applications. Micro and nano technologies. Elsevier; 2023. p. 469–87. doi:10.1016/B978-0-323-99546-7.00011-2. [Google Scholar] [CrossRef]

72. Usmani SM, Stephan I, Hübert T, Kemnitz E. Nano metal fluorides for wood protection against fungi. ACS Appl Nano Mater. 2018;1(4):1444–9. doi:10.1021/acsanm.8b00144. [Google Scholar] [CrossRef]

73. Nisar P, Ali N, Rahman L, Ali M, Shinwari ZK. Antimicrobial activities of biologically synthesized metal nanoparticles: an insight into the mechanism of action. J Biol Inorg Chem. 2019;24(7):929–41. doi:10.1007/s00775-019-01717-7. [Google Scholar] [PubMed] [CrossRef]

74. Casado-Sanz MM, Silva-Castro I, Ponce-Herrero L, Martín-Ramos P, Martín-Gil J, Acuña-Rello L. White-rot fungi control on populus spp. Wood by pressure treatments with silver nanoparticles, chitosan oligomers and propolis. Forests. 2019;10(10):885. doi:10.3390/f10100885. [Google Scholar] [CrossRef]

75. Reinprecht L, Repák M, Iždinský J, Vidholdová Z. Decay resistance of nano-zinc oxide, and PEG 6000, and thermally modified wood. Forests. 2022;13(5):731. doi:10.3390/f13050731. [Google Scholar] [CrossRef]

76. Usmani SM, Plarre R, Hübert T, Kemnitz E. Termite resistance of pine wood treated with nano metal fluorides. Eur J Wood Prod. 2020;78(3):493–9. doi:10.1007/s00107-020-01522-z. [Google Scholar] [CrossRef]

77. Kayalvizhi Nangai E, Saravanan S. Synthesis, fabrication and testing of polymer nanocomposites: a review. Mat Today: Proc. 2023;81:91–7. doi:10.1016/j.matpr.2021.02.261. [Google Scholar] [CrossRef]

78. Shakeel A, Rizwan K, Farooq U, Iqbal S, Iqbal T, Awwad NS, et al. Polymer based nanocomposites: a strategic tool for detection of toxic pollutants in environmental matrices. Chemosphere. 2022;303:134923. doi:10.1016/j.chemosphere.2022.134923. [Google Scholar] [PubMed] [CrossRef]

79. Rasool A, Rizwan M, ur Rehman Qureshi A, Rasheed T, Bilal M. 10-Thermo-responsive functionalized polymeric nanocomposites, Smart Polymer Nanocomposites. In: Ali N, Bilal M, Khan A, Nguyen TA, Gupta RK, editors. Smart polymer nanocomposites. Micro and nano technologies. Elsevier; 2023. p. 219–40. doi:10.1016/B978-0-323-91611-0.00013-X. [Google Scholar] [CrossRef]

80. Saleh TA. Nanomaterials: classification, properties, and environmental toxicities. Environ Technol Innovat. 2020;20:101067. doi:10.1016/j.eti.2020.101067. [Google Scholar] [CrossRef]

81. Patel GM, Shah V, Bhaliya J, Pathan P, Nikita KM. 2-Polymer-based nanomaterials: an introduction. In: Ali N, Bilal M, Khan A, Nguyen TA, Gupta RK, editors. Smart polymer nanocomposites. Micro and nano technologies. Elsevier; 2023. p. 27–59. doi:10.1016/B978-0-323-91611-0.00018-9. [Google Scholar] [CrossRef]

82. Khan I, Khan I, Saeed K, Ali N, Zada N, Khan A, et al. 7-Polymer nanocomposites: an overview. In: Ali N, Bilal M, Khan A, Nguyen TA, Gupta RK, editors. Smart polymer nanocomposites. Micro and nano technologies. Elsevier; 2023. p. 167–84. doi:10.1016/B978-0-323-91611-0.00017-7. [Google Scholar] [CrossRef]

83. Rallini M, Kenny JM. 3-Nanofillers in polymers. In: Jasso-Gastinel CF, Kenny JM, editors. Modification of polymer properties. William Andrew Publishing; 2017. p. 47–86. doi:10.1016/B978-0-323-44353-1.00003-8. [Google Scholar] [CrossRef]

84. Tamayo L, Azócar M, Kogan M, Riveros A, Páez M. Copper-polymer nanocomposites: an excellent and cost-effective biocide for use on antibacterial surfaces. Mater Sci Eng. 2016;C. 69:1391–409. doi:10.1016/j.msec.2016.08.041. [Google Scholar] [PubMed] [CrossRef]

85. Teles F, Martins G, Antunes F. Fire retardancy in nanocomposites by using nanomaterial additives. J Anal Appl Pyrolysis. 2022;163:105466. doi:10.1016/j.jaap.2022.105466. [Google Scholar] [CrossRef]

86. kordi A, Adibnazari S, Imam A, Najafi M. Effects of two- and three-dimensional graphene-based nanomaterials on the fatigue behavior of epoxy nanocomposites. Mater Today Commun. 2020;24:101194. doi:10.1016/j.mtcomm.2020.101194. [Google Scholar] [CrossRef]

87. Ahmed L, Zhang B, Hatanaka LC, Mannan MS. Application of polymer nanocomposites in the flame retardancy study. J Loss Prev Process Ind. 2018;55(B):381–91. doi:10.1016/j.jlp.2018.07.005. [Google Scholar] [CrossRef]

88. Janesch J, Czabany I, Hansmann C, Mautner A, Rosenau T, Gindl-Altmutter W. Transparent layer-by-layer coatings based on biopolymers and CeO2 to protect wood from UV light. Prog Org Coat. 2020;138:105409. doi:10.1016/j.porgcoat.2019.105409. [Google Scholar] [CrossRef]

89. Harandi D, Ahmadi H, Mohammadi Achachluei M. Comparison of TiO2 and ZnO nanoparticles for the improvement of consolidated wood with polyvinyl butyral against white rot. Int Biodeterior Biodegrad. 2016;108(2):142–8. doi:10.1016/j.ibiod.2015.12.017. [Google Scholar] [CrossRef]

90. Žigon J, Centa UG, Remškar M, Humar M. Application and characterization of a novel PVDF-HFP/PVP polymer composite with MoO3 nanowires as a protective coating for wood. Sci Rep. 2023;13(1):3429. doi:10.1038/s41598-023-30622-y. [Google Scholar] [PubMed] [CrossRef]

91. Hazarika A, Maji TK. Strain sensing behavior and dynamic mechanical properties of carbon nanotubes/nanoclay reinforced wood polymer nanocomposite. Chem Eng J. 2014;247:33–41. doi:10.1016/j.cej.2014.02.069. [Google Scholar] [CrossRef]

92. Zhu Q, Chua MH, Ong PJ, Cheng Lee JJ, Le Osmund Chin K, Wang S, et al. Recent advances in nanotechnology-based functional coatings for the built environment. Mat Today Adv. 2022;15:100270. doi:10.1016/j.mtadv.2022.100270. [Google Scholar] [CrossRef]

93. Blanchet P, Landry V. 13-Nanocomposite coatings and plasma treatments for wood-based products. In: Ansell MP, editor. Wood composites. Woodhead Publishing; 2015. p. 335–55. doi:10.1016/B978-1-78242-454-3.00013-5. [Google Scholar] [CrossRef]

94. Ulaeto SB, Rajan R, Pancrecious JK, Rajan TPD, Pai BC. Developments in smart anticorrosive coatings with multifunctional characteristics. Prog Org Coat. 2017;111:294–314. doi:10.1016/j.porgcoat.2017.06.013. [Google Scholar] [CrossRef]

95. Yadav K, Kumar A. Chapter 7-Introduction of smart coatings in various directions. In: Kumar A, Behera A, Nguyen TA, Bilal M, Gupta RK, editors. Antiviral and antimicrobial smart coatings. Elsevier; 2023. p. 219–38. [Google Scholar]

96. Bao W, Deng Z, Zhang S, Ji Z, Zhang H. Next-generation composite coating system: nanocoating. Front Mater. 2019;6:72. doi:10.3389/fmats.2019.00072. [Google Scholar] [CrossRef]

97. Makhlouf ASH. 1-Current and advanced coating technologies for industrial applications. In: Makhlouf ASH, Tiginyanu I, editors. Nanocoatings and ultra-thin films. Woodhead publishing series in metals and surface engineering. Woodhead Publishing; 2011. p. 3–23. doi:10.1533/9780857094902.1.3. [Google Scholar] [CrossRef]

98. Nguyen-Tri P, Tran HN, Plamondon CO, Tuduri L, Vo DN, Nanda S, et al. Recent progress in the preparation, properties and applications of superhydrophobic nano-based coatings and surfaces: a review. Prog Org Coat. 2019;132:235–56. doi:10.1016/j.porgcoat.2019.03.042. [Google Scholar] [CrossRef]

99. Wang S, Liu C, Liu G, Zhang M, Li J, Wang C. Fabrication of superhydrophobic wood surface by a sol-gel process. Appl Surf Sci. 2011;258(2):806–10. doi:10.1016/j.apsusc.2011.08.100. [Google Scholar] [CrossRef]

100. Tuong VM, Huyen NV, Kien NT, Dien NV. Durable epoxy@ZnO coating for improvement of hydrophobicity and color stability of wood. Polymers. 2019;11(9):1388. doi:10.3390/polym11091388. [Google Scholar] [PubMed] [CrossRef]

101. Duan X, Liu S, Huang E, Shen X, Wang Z, Li S, et al. Superhydrophobic and antibacterial wood enabled by polydopamine-assisted decoration of copper nanoparticles. Coll Surf A: Physicochem Eng Aspects. 2020;602(8):125145. doi:10.1016/j.colsurfa.2020.125145. [Google Scholar] [CrossRef]

102. Lazari M, Elmi F. Structural study of coated wood with superhydrophobic chitosan/silica hybrid nanocomposite in seawater. Prog Org Coat. 2024;186(4):108076. doi:10.1016/j.porgcoat.2023.108076. [Google Scholar] [CrossRef]

103. Kumar SS, Kakooei S. Chapter 21-Container-based smart nanocoatings for corrosion protection. In: Rajendran S, Nguyen TA, Kakooei S, Yeganeh M, Li Y, editors. Corrosion protection at the nanoscale. Micro and nano technologies. Elsevier; 2020. p. 403–21. doi:10.1016/B978-0-12-819359-4.00021-0. [Google Scholar] [CrossRef]

104. El-Naggar ME, Aldalbahi A, Khattab TA, Hossain M. Facile production of smart superhydrophobic nanocomposite for wood coating towards long-lasting glow-in-the-dark photoluminescence. Luminescence. 2021;36(8):2004–13. doi:10.1002/bio.4137. [Google Scholar] [PubMed] [CrossRef]

105. Mohapatra S, Lin Y, Goh SG, Ng C, You L, Tran NH, et al. Quaternary ammonium compounds of emerging concern: classification, occurrence, fate, toxicity and antimicrobial resistance. J Hazard Mater. 2023;445:130393. doi:10.1016/j.jhazmat.2022.130393. [Google Scholar] [PubMed] [CrossRef]

106. Zhang C, Cui F, Zeng GM, Jiang M, Yang ZZ, Yu ZG, et al. Quaternary ammonium compounds (QACsa review on occurrence, fate and toxicity in the environment. Sci Total Environ. 2015;518–519:352–62. doi:10.1016/j.scitotenv.2015.03.007. [Google Scholar] [PubMed] [CrossRef]

107. Noroozi-Shad N, Gholizadeh M, Sabet-Sarvestani H. Quaternary phosphonium salts in the synthetic chemistry: recent progress, development, and future perspectives. J Mol Struct. 2022;1257:132628. doi:10.1016/j.molstruc.2022.132628. [Google Scholar] [CrossRef]

108. Wang G, Yang L, Jiang L, Chen J, Jing Q, Mai Y, et al. A new class of quaternary ammonium compounds as potent and environmental friendly disinfectants. J Clean Prod. 2022;379:134632. doi:10.1016/j.jclepro.2022.134632. [Google Scholar] [PubMed] [CrossRef]

109. Song J, Kong H, Jang J. Bacterial adhesion inhibition of the quaternary ammonium functionalized silica nanoparticles. Coll Surf B: Biointerf. 2011;82(2):651–6. doi:10.1016/j.colsurfb.2010.10.027. [Google Scholar] [PubMed] [CrossRef]

110. Elena P, Miri K. Formation of contact active antimicrobial surfaces by covalent grafting of quaternary ammonium compounds. Coll Surf B: Biointerf. 2018;169:195–205. doi:10.1016/j.colsurfb.2018.04.065. [Google Scholar] [PubMed] [CrossRef]

111. Dan W, Gao J, Qi X, Wang J, Dai J. Antibacterial quaternary ammonium agents: chemical diversity and biological mechanism. Eur J Med Chem. 2022;243:114765. doi:10.1016/j.ejmech.2022.114765. [Google Scholar] [PubMed] [CrossRef]

112. Morandini A, Leonetti B, Riello P, Sole R, Gatto V, Caligiuri I, et al. Synthesis and antimicrobial evaluation of bis-morpholine triazine quaternary ammonium salts. ChemMedChem. 2021;16(20):3172–6. doi:10.1002/cmdc.202100409. [Google Scholar] [PubMed] [CrossRef]

113. Druvari D, Antonopoulou A, Lainioti GC, Vlamis-Gardikas A, Bokias G, Kallitsis JK. Preparation of antimicrobial coatings from cross-linked copolymers containing quaternary dodecyl-ammonium compounds. Int J Mol Sci. 2021;22(24):13236. doi:10.3390/ijms222413236. [Google Scholar] [PubMed] [CrossRef]

114. Zhang N, Ma S. Recent development of membrane-active molecules as antibacterial agents. Eur J Med Chem. 2019;184:111743. doi:10.1016/j.ejmech.2019.111743. [Google Scholar] [PubMed] [CrossRef]

115. Saif MJ, Anwar J, Munawar MA. A novel application of quaternary ammonium compounds as antibacterial hybrid coating on glass surfaces. Langmuir. 2009;25(1):377–9. doi:10.1021/la802878p. [Google Scholar] [PubMed] [CrossRef]

116. Wang L, Zhao X, Ren S, Hu Z, Wang Y. Application of pH-responsive functionalized hollow mesoporous organosilica nanoparticles for wood preservation. Mat Design. 2023;225(9):111538. doi:10.1016/j.matdes.2022.111538. [Google Scholar] [CrossRef]

117. Wang L, Wang T, Hao R, Wang Y. Construction strategy and mechanism of a novel wood preservative with excellent antifungal effects. Molecules. 2024;29(5):1013. doi:10.3390/molecules29051013. [Google Scholar] [PubMed] [CrossRef]

118. Daniels GC, Iezzi EB, Fulmer PA, Wynne JH. Synergistic antimicrobial and surface free energy of sol-gel coatings containing fluorosilanes and quaternary ammonium salts. Prog Org Coat. 2016;95:91–9. doi:10.1016/j.porgcoat.2016.02.021. [Google Scholar] [CrossRef]

119. Tominaga C, Shitomi K, Miyaji H, Kawasaki H. Antibacterial photocurable acrylic resin coating using a conjugate between silver nanoclusters and alkyl quaternary ammonium. ACS Appl Nano Mater. 2018;1(9):4809–18. doi:10.1021/acsanm.8b01010. [Google Scholar] [CrossRef]

120. Mathew RT, Cooney RP, Doyle CS, Swift S, Haessler C. Anchored quaternary ammonium salts adsorbed on polyurethane film surfaces. Prog Org Coat. 2020;138(16):105343. doi:10.1016/j.porgcoat.2019.105343. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools