Open Access

Open Access

ARTICLE

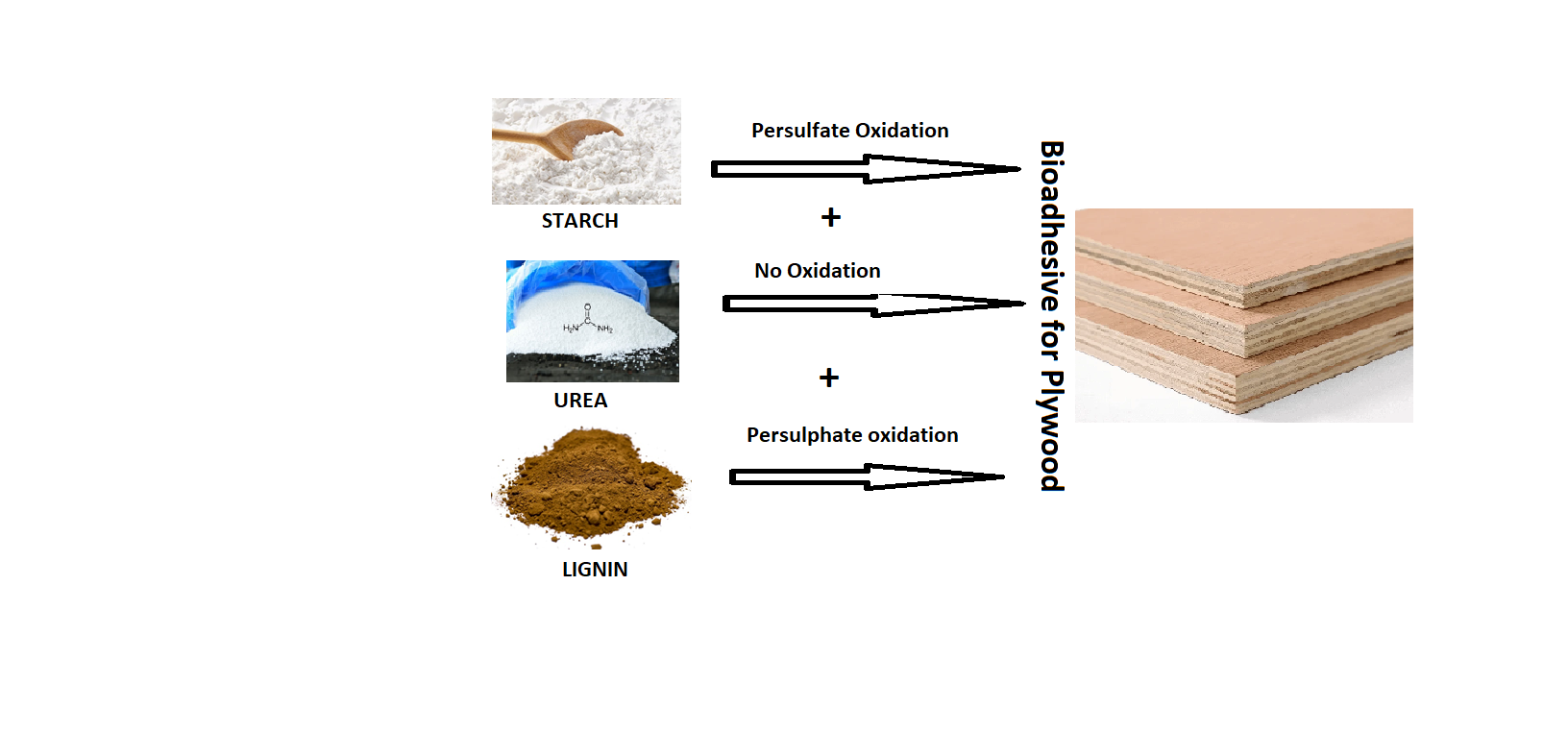

Plywood Bio-Adhesives by Oxidized Lignin Urea Bridged with Oxidized Starch

1 Department of Wood and Paper Sciences, Faculty of Natural Resources, Semnan University, Semnan, 35131-19111, Iran

2 LERMAB-ENSTIB, University of Lorraine, 27 rue Philippe Seguin, Epinal, 88000, France

* Corresponding Authors: Hamed Younesi-Kordkheili. Email: ; Antonio Pizzi. Email:

(This article belongs to the Special Issue: Renewable and Biosourced Adhesives-2023)

Journal of Renewable Materials 2026, 14(1), 1 https://doi.org/10.32604/jrm.2025.02025-0179

Received 12 September 2025; Accepted 28 October 2025; Issue published 23 January 2026

Abstract

The aim of this research was to synthesize a new totally bio wood adhesive entailing the use of oxidized starch (OST), urea, and oxidized lignin (OL). For this reason, non-modified (L) and oxidized lignin (OL) at different contents (20%, 30%, and 40%) were used to prepare the starch-urea-lignin (SUL) and starch-urea-oxidized lignin (SUOL) resin. Sodium persulfate (SPS) as oxidizer was employed to oxidize both starch and lignin. Urea was just used as a low cost and effective crosslinker in the resin composition. The properties of the synthesized resins and the plywood panels bonded with them were measured according to relevant standards. The viscosity and gel time of the SUOL resins containing oxidized lignin are respectively higher and faster than for non-modified lignin (SUL). The lignin phenolic hydroxyl groups (-OH) proportion was markedly increased by oxidation as shown by Fourier Transform Infrared (FTIR) spectrometry. The molecular mass and the polydispersity of the lignin did also decrease by its oxidization pretreatment. DSC analysis showed a decrease of the glass transition temperature of the lignin (Tg) due to its oxidation. The thermal analysis of the oxidized lignin SUOL resin also showed that it had a lower peak temperature than the SUL equivalent non-modified lignin resin. The plywood panels bonded with oxidized lignin gave acceptable bending modulus, bending strength, peak temperature by thermal analysis and dry shear strength as well as a better plywood dimensional stability when used in the SUOL formulation. The synthesized SUOL adhesive is a lignin-derived, totally bio, no-aldehyde added, inexpensive resin applicable to bond plywood.Graphic Abstract

Keywords

Cite This Article

Copyright © 2026 The Author(s). Published by Tech Science Press.

Copyright © 2026 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools