Open Access

Open Access

ARTICLE

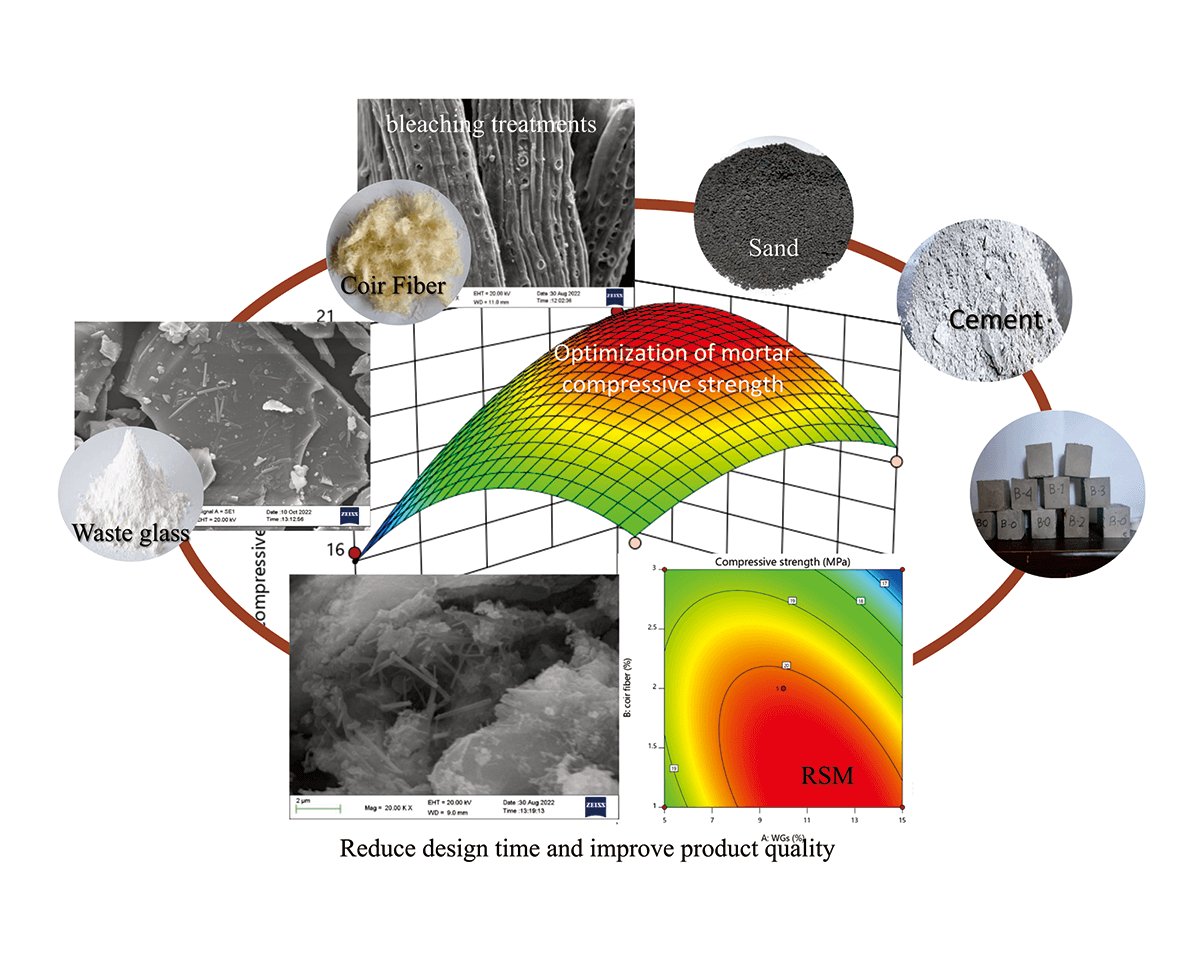

Optimization of Mortar Compressive Strength Prepared with Waste Glass Aggregate and Coir Fiber Addition Using Response Surface Methodology

1

Department of Civil Engineering, Universitas Abulyatama, Aceh Besar, 23372, Indonesia

2

Advanced Engineering Materials and Nano Technology Research Center, Universitas Abulyatama, Aceh Besar, 23372, Indonesia

3

Faculty of Fisheries, Universitas Abulyatama, Aceh Besar, 23372, Indonesia

4

Department of Mechanical Engineering, Universitas Abulyatama, Aceh Besar, 23372, Indonesia

5

Advanced Engineering Materials and Composites Research Center (AEMC), Department of Mechanical and Manufacturing

Engineering, Universiti Putra Malaysia, Selangor, 43400, Malaysia

6

Department of Mechanical Engineering, Universitas Malahayati, Lampung, 35153, Indonesia

7

Department of Civil Engineering, Millitary College of Engineering, Risalpur, 24080, Pakistan

8

Department of Construction Management, Qujing Normal University, Qujing, 655011, China

* Corresponding Author: Cut Rahmawati. Email:

(This article belongs to the Special Issue: Sustainable Concrete with Recyclable Materials)

Journal of Renewable Materials 2023, 11(10), 3751-3767. https://doi.org/10.32604/jrm.2023.028987

Received 21 January 2023; Accepted 24 March 2023; Issue published 10 August 2023

Abstract

Waste Glass (WGs) and Coir Fiber (CF) are not widely utilized, even though their silica and cellulose content can be used to create construction materials. This study aimed to optimize mortar compressive strength using Response Surface Methodology (RSM). The Central Composite Design (CCD) was applied to determine the optimization of WGs and CF addition to the mortar compressive strength. Compressive strength and microstructure testing with Scanning Electron Microscope (SEM), Fourier-transform Infrared Spectroscopy (FT-IR), and X-Ray Diffraction (XRD) were conducted to specify the mechanical ability and bonding between the matrix, CF, and WGs. The results showed that the chemical treatment of CF produced 49.15% cellulose, with an average particle size of 1521 µm. The regression of a second-order polynomial model yielded an optimum composition consisting of 12.776% WGs and 2.344% CF with a predicted compressive strength of 19.1023 MPa. C–S–H gels were identified in the mortars due to the dissolving of SiO2 in WGs and cement. The silica from WGs increased the C–S–H phase. CF plays a role in preventing, bridging, and branching micro-cracks before reaching maximum stress. WGs aggregates and chemically treated CF are suitable to be composited in mortar to increase compressive strength.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools