Open Access

Open Access

ARTICLE

Physical and Mechanical Properties of Gmelina Wood (Gmelina arborea Roxb.) Modified with Furfuryl Alcohol-Tannin

1 Faculty of Forestry and Environment, Department of Forest Products, IPB University, Bogor, 16680, Indonesia

2 Research Center for Biomass and Bioproducts, National Research and Innovation Agency (BRIN), Cibinong, 16915, Indonesia

3 The Papua New Guinea University of Technology, Independence Drive, East Taraka, Lae 411, Papua New Guinea

4 College of Landscape and Horticulture, Yunnan Agricultural University, Kunming, 650201, China

5 INRAE, LERMAB, Université de Lorraine, Nancy, 54000, France

* Corresponding Authors: Mahdi Mubarok. Email: ; Saefudin. Email:

Journal of Renewable Materials 2025, 13(4), 731-752. https://doi.org/10.32604/jrm.2024.057476

Received 19 August 2024; Accepted 28 November 2024; Issue published 21 April 2025

Abstract

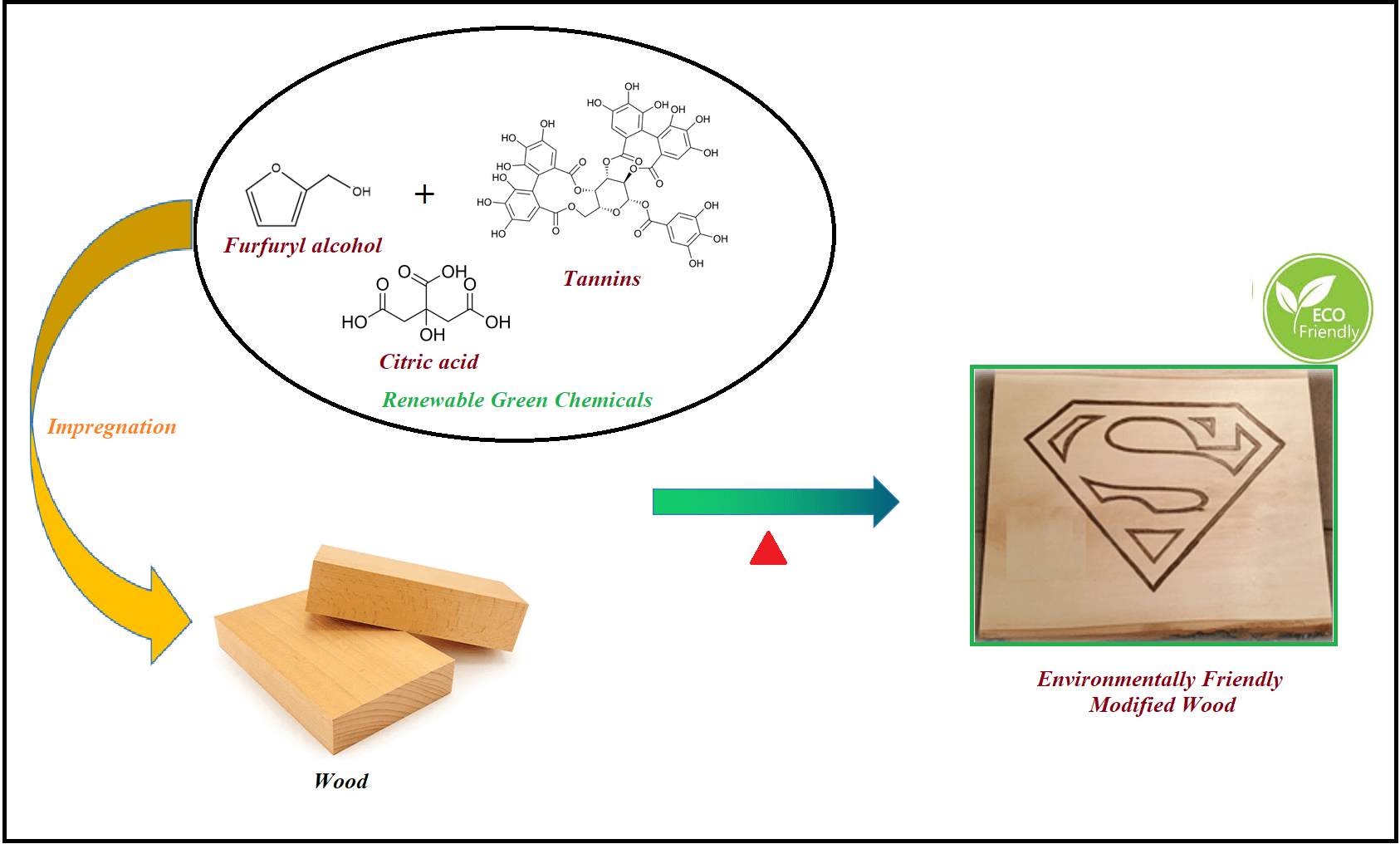

Furfurylation, a renowned chemical modification technique, uses furfuryl alcohol to enhance the properties of wood. This technology can be further refined by incorporating renewable tannins, which promote cross-linking with furfuryl alcohol. This study investigates the effects of furfurylation and tannin-modified furfurylation on the physical and mechanical properties of tropical Gmelina wood (Gmelina arborea Roxb.). Experiments involved impregnating Gmelina wood with aqueous solutions of furfuryl alcohol (FA) at 40% and 70% concentrations, as well as FA-tannin combinations (FA 40%-TA and FA 70%-TA), followed by polymerization at 103°C. The results demonstrated that both FA and FA-tannin treatments significantly improved the wood’s physical and mechanical properties. Notably, FA-tannin treatments achieved anti-swelling efficiency comparable to FA alone. However, the addition of tannins (FA 70%-TA) enhanced leaching resistance by up to 47%, contributing to a more environmentally sustainable modification process. Mechanically, the inclusion of tannins in FA 70%-TA slightly increased the modulus of elasticity (14%~8732 kg/cm2) and the modulus of rupture (9%~40.9 kg/cm2). Furthermore, the tannin addition imparted a darker color to the modified wood, enhancing its aesthetic appeal. This study highlights the potential of tannin-modified furfurylation to advance wood modification technology, combining improved performance with environmental benefits.Graphic Abstract

Keywords

Wood is a fundamental forest product widely utilized in the construction of buildings, furniture, and various wood-based products in the woodworking industry. However, despite the high demand for wood, its production, particularly from natural forests, is declining [1]. Between 2021 and 2022, deforestation in Indonesia was recorded at 104 thousand hectares [2], and as of May 2024, 89.17% of wood production originated from Industrial Plantation Forests (HTI) [3], which primarily utilizes fast-growing wood species. Although these species are rapidly renewable, they possess certain limitations due to their inferior properties. To address the challenge of enhancing these properties while also reducing deforestation, wood modification technology has emerged as a promising solution. This technology can extend the useful life of wood and reduce the need to frequently replace wood products serving similar functions.

Wood modification technology has been developed to overcome the inherent limitations of wood by enhancing its dimensional stability, reducing water absorption, improving wood strength, and increasing resistance to decay, while taking into account the environmental impact of modified wood products. Among these technologies, thermal treatment has proven effective in improving wood quality, particularly by enhancing dimensional stability and protection systems without the use of biocides [4]. However, this method, particularly when treatment exceeds 200°C, may lead to the degradation of hemicellulose, a critical component that cross-links cellulose and lignin in wood cell walls, thereby negatively affecting the mechanical properties of the wood. At low to moderate thermal modification temperatures (around 170°C), bending strength, shear strength parallel to the grain, and tensile strength tend to decrease, while compressive strength parallel to the grain and modulus of elasticity increase [5–8]. Despite these considerations, this modification method remains favorable in certain market segments due to its economic viability, environmental benefits, and other advantages [9–12].

In addition to thermal treatment, chemical modification offers another alternative for improving wood quality by impregnating it with active chemicals. Extensive research has explored various chemical modification techniques, including esterification through acetylation [13,14], polyester formation [15–19], and polymerization processes using substances such as polystyrene [20,21], methyl methacrylate [22–24], furfuryl alcohol [25–29], and polyfurfuryl alcohol-tannins [30]. While numerous methods have been explored, only a few, such as acetylation, furfurylation, and polymer formation (using phenol formaldehyde, melamine formaldehyde, and DMDHEU [1,3-dimethylol-4,5-dihydroxyethyleneurea]), have been successfully scaled for industrial applications [4,10] although the cost of modified wood products remains a key consideration and limits their use to specific applications. Even so, most of these chemically modified woods demonstrate enhanced performance in terms of physical, mechanical, and durability properties, particularly their resistance to termites [4,10]. Other industrially applied wood modification techniques include treatments with inorganic solutions, surface charring, and wood densification, though these nowadays still cover niche market [10].

Given the renewable nature of materials and the promising properties of furfurylation using furfuryl alcohol (FA), this method has attracted significant interest for further development in the field of wood modification. Furfurylation is a chemical modification technique that imparts superior properties to wood, such as resistance to wood-destroying organisms, enhanced hardness, and improved dimensional stability [14,29,30]. However, research on this technique remains limited, particularly for tropical wood species found in Indonesia [29]. Furthermore, the development of methods to enhance the reactivity of furfuryl alcohol during the process, thereby facilitating its intensive polymerization and improving the leaching resistance of the resulting furfurylated wood, particularly in combination with renewable tannins, is still in its early stages. Therefore, this study aimed to evaluate the effects of incorporating tannins into existing furfurylation technology on the physical and mechanical properties of the resulting modified wood.

The wood species used in this study was Gmelina wood (Gmelina arborea Roxb.), sourced from logs approximately 7 years old, harvested from Cinangneng Village, Bogor District, Indonesia. A readily available tannin extract solution (with a solid content of 2.01% and a pH of 4.00) was obtained from mahogany wood bark. The bark was previously collected from a sawmill industry in Ciamis, West Java, Indonesia. The extraction process, as described by Santoso and Abdurachman [31], involved boiling the bark in water at a mass ratio of 1:3 at 70°C–80°C for three hours, with the procedure repeated twice to maximize extraction. Furfuryl alcohol (FA) with a purity of 97% or greater and citric acid monohydrate with a purity of 98% or greater were both obtained from Merck (Sigma-Aldrich) for use in the wood modification experiments.

Gmelina wood logs were prepared for mechanical property testing following the DIN 52186 (1978) standard [32]. The logs were cut into clear samples measuring 20 cm (longitudinal/L) × 1 cm (transversal/T) × 1 cm (radial/R), with a total of 25 samples prepared for the tests. The physical properties of the wood were assessed according to the BS 373:1957 standard [33], while the leaching test was conducted in accordance with the EN 84 (1997) standard [34]. For these tests, the sample size was modified to measure 1 cm (L) × 2.5 cm (T) × 2.5 cm (R), with 25 samples used for each test. Additionally, color testing was carried out using the samples measuring 20 cm (L) × 5 cm (T) × 1 cm (R).

2.3 Preparation of Impregnation Solution

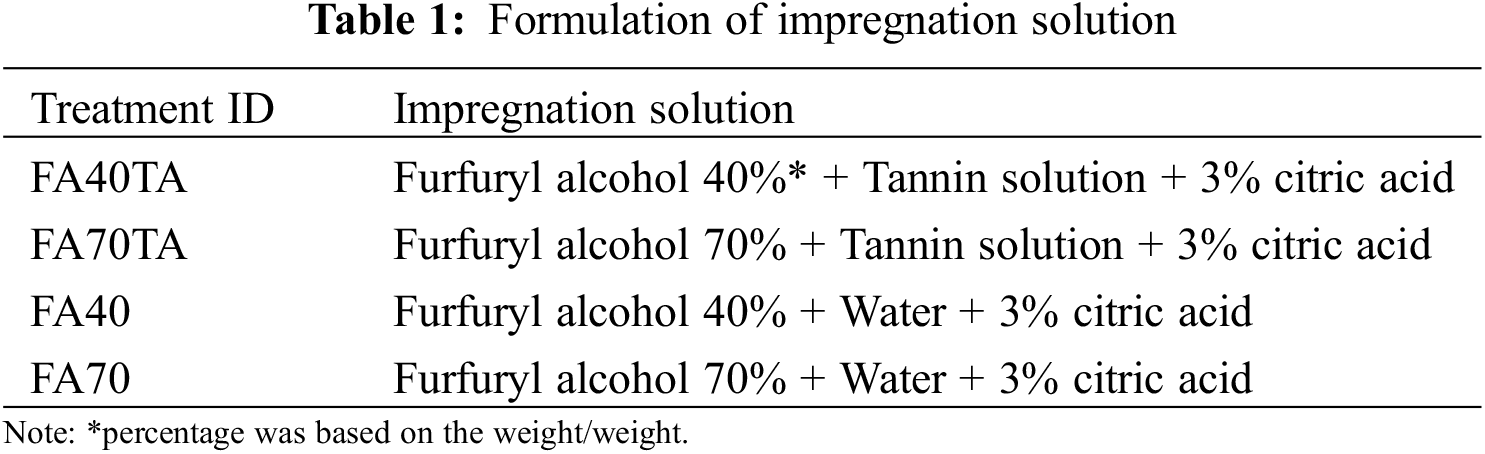

The wood samples were dried in an oven at 103°C for 48 h to obtain their initial weight (W0) and volume (V0). After drying, the samples were placed in a vacuum machine. A solution of FA with a 3% w/w citric acid catalyst was then impregnated into the gmelina wood samples. The formulation of the impregnation solution was as follows (Table 1).

The impregnation system was initially subjected to a vacuum of 0 MPa for 1 h. The system was then brought back to room conditions and pressurized to 1 MPa for 2 h. After the vacuum and pressure process was completed, the system was returned to room conditions, and the wood samples were left to soak for 48 h to maximize the penetration of the impregnating solution into the wood.

Next, the wood was removed from the impregnation chamber, drained of excess solution, weighed, and its volume was measured. The impregnated wood was then left to stand for approximately three days at room temperature (±27°C; 70% relative humidity) to reduce the water content. Afterward, the samples were wrapped in aluminum foil and dried in an oven at 103 ± 2°C for 48 h. The wood samples were then removed from the oven, weighed to obtain the final weight after modification (W1), and their dimensions were measured.

Subsequently, the modified wood samples were conditioned indoors for two weeks before further characterization. For comparison, some untreated wood samples (control wood) were also prepared without impregnation.

2.4.1 Impregnation Effectiveness

To determine the effectiveness of the impregnation process, solution uptake, swelling, weight percent gain (WPG), and bulking effect (BE) were determined.

The solution uptake was determined by measuring the weight of the sample after impregnation and that in the oven-dried condition before impregnation. Solution uptake was calculated using Eq. (1):

where W0 is the dry weight of the sample before impregnation, and W1 is the wet weight of the sample immediately after impregnation.

The swelling value is determined by comparing the volume change and the difference between oven-dry conditions (V0) and conditions after the impregnation process (V1) using Eq. (2) below:

where V0 is the initial dry volume of the sample before impregnation, and V1 is the wet volume of the sample immediately after impregnation.

2.4.4 Weight Percent Gain (WPG)

Weight percent gain (WPG) is the weight gain percentage due to the modification process/furfurylation. The WPG value was calculated using Eq. (3):

where W0 is the dry weight of the sample before impregnation, and W2 is the dry weight of the sample after modification.

The bulking effect is the percentage volume difference of the sample in oven-dry conditions before and after modification. The bulking effect was calculated using Eq. (4) below:

where V0 is the initial dry volume of the sample before impregnation, and V2 is the dry volume of the sample immediately after modification.

2.5 Physical Properties of Modified Wood (Furfurylated Wood)

Moisture content (MC) was determined after conditioning the samples, either control or modified, for at least two weeks at room temperature (±27°C; 70% RH). The test sample was first weighed to obtain the initial weight (BA) and then dried at 103 ± 2°C until a constant weight was achieved. Moisture content was calculated using Eq. (5) below:

where W2 is the dry weight of the sample, and W3 is the weight of the sample after conditioning.

The density was determined by measuring the weight and volume of the samples after conditioning. The density was calculated using Eq. (6) below:

where W3 and V3 are the weight and volume of the sample, respectively, after the conditioning period.

Water absorption (WA) was determined by measuring the weight of the modified wood samples before and after 24, 48 h, and 14 days of soaking. The WA value was calculated using Eq. (7) below:

where W3 is the weight of the sample after conditioning before soaking and W4 is the weight of the sample after soaking.

The dimensional change (DC) was determined by comparing the volume change of the samples before and after 24, 48 h, and 14 days of soaking. The DC value was calculated using Eq. (8) below:

where V3 is the initial volume of the sample before soaking and V4 is the wet volume of the sample immediately after soaking.

2.5.5 Anti Swelling Efficiency

Anti-swelling efficiency (ASE) is the percentage of anti-swelling of modified wood compared to control wood after soaking in water for a certain duration. The anti-swell efficiency was calculated using Eq. (9) below:

where DC0 is the dimensional change of control wood after soaking and DC1 is the dimensional change of treated wood after soaking.

The leaching percentage was based on the EN 84 (1997) standard [34]. The leaching test was carried out by soaking the wood test samples for 14 days with nine water changes. During immersion, the quantity of water used was at least ten folds the volume of the wood sample. The water was changed on the first and second days of immersion; then, the water was changed again seven times for the remaining 12 days, provided that the interval was not less than one day and not more than three days. The leaching value was then calculated using Eq. (10) below:

where L is the leaching percentage of the sample, W3 is the dry weight of the sample after conditioning before soaking, and W5 is the dry weight of the sample after soaking.

Color testing is carried out using the CIELAB method to indicate color changes. This method was carried out by obtaining the values of L*, a*, and b* from sample photography using the Adobe Photoshop software. L* indicates light indication, with a value of 0 to 100 (black to white; a* indicates a color indication from green to red, with +a* from a value of 0 to 80 indicating a red color and −a* with a value of −80 to 0 indicating a green color; b* indicates a blue to yellow color, with +b* from 0 to 70 indicating a yellow color and −b* from −70 to 0 indicating a blue color [35]. Color change (∆E) was calculated based on the CIELab method [36] using Eq. (11) below:

where ∆E is the color change between the compared samples, and ∆L*, ∆a*, and ∆b* are the differences in the L*, a*, and b* values between the compared samples, respectively.

According to Hunter Lab [36], color changes can be classified based on the following table referring to Hadi et al. [29] (Table 2):

The mechanical properties were determined using three points static bending tests. Wood specimens were measured based on the DIN 52186 (1978) standard [32] with a sample size of 200 × 10 × 10 mm3 (L, T, R). Testing was carried out using a Universal Testing Machine (UTM)—Instron 3369. The applied loading speed during testing was 2 mm/min. The MOE and MOR values were calculated using Eqs. (12) and (13):

where MOR is the modulus of rupture (kg/cm2); MOE is the modulus of elasticity (kg/cm2); P is the maximum load (kg); L is the length of test sample (cm); b is the width of test sample (cm); h is the thickness of the test sample (cm); ΔP is the change in load used (kg); and Δy is the change in deflection for every change in load (cm).

Data obtained from testing the physical and mechanical properties were analyzed using descriptive statistical methods with IBM SPSS. The analysis followed a Completely Randomized Design (CRD) with five replications for each test.

A solution uptake test was conducted to measure the amount of impregnation solution absorbed by the wood. This uptake depends on various factors, including the wood species’ anatomy, density, the molecular weight and polarity of the impregnated materials, the solvent used, and the impregnation method [16,30]. The results showed that the impregnation of gmelina wood with both FA (FA40 and FA70) and FA-tannin (FA40TA and FA70TA) solutions proceeded smoothly, resulting in a solution absorption value of over 100% (Fig. 1; each value in Fig. 1 represents the average of five samples).

Figure 1: Solution uptake of FA & FA-tannin impregnation solution (values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

The pressed vacuum impregnation treatment enhanced penetration into the wood, as the applied pressure displaced air in the wood cell cavities with the impregnation solution [37]. Additionally, gmelina wood’s specific gravity of 0.37–0.44 g/cm3 and its numerous cavities facilitated the entry and filling of these cavities by the impregnation liquid [38].

The FA solution without tannins provided a higher absorption value compared to the FA-tannin solution. Analysis of variance (ANOVA) with 95% confidence indicated that FA and FA-TA impregnation significantly affected the solution uptake value. Duncan’s post-hoc test revealed that FA70 impregnation had a significantly different effect compared to FA40TA, FA40, and FA70TA, with higher FA concentrations leading to better absorption.

This finding aligns with Furuno et al. [39], who noted that the presence of impregnated materials in wood cells is influenced by the molecular weight of those materials. The addition of tannin can reduce solution absorption, as tannin has a higher molecular weight (500–20,000 g/mol) compared to water (18.02 g/mol) and FA (98 g/mol) [40]. Consequently, tannin particles, being larger than water molecules and FA, struggle to penetrate wood cell walls [30].

The swelling value, or volume expansion, that occurs in wood during impregnation indicates the amount of impregnating solution absorbed by the wood, leading to its volume expansion. In line with the high percentage of solution uptake, the volume expansion (swelling) of the wood samples in the impregnating solution followed a similar trend. FA impregnation without tannin resulted in higher swelling values up to 0.42% differences than FA impregnation with tannin (Fig. 2; each value in Fig. 2 represents the average of five samples). However, since the tannin concentration in these treatments was not high, Duncan’s post-hoc test showed that the differences between FA and FA-tannin impregnation treatments were not statistically significant.

Figure 2: Swelling values of the wood impregnated with FA and FA-tannin solution (values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

The increase in wood volume occurs due to the entry of the impregnating solution into the cell cavities and walls during the vacuum-pressing process, including the soaking phase [16]. The initial vacuum removes air trapped in the cell lumen, opening up the empty cells and making them more accessible to the impregnation process. The application of pressure ensures deep and uniform penetration, contributing to the expansion of the wood’s volume [41].

3.3 Weight Percent Gain ( WPG)

Weight percent gain (WPG) is a crucial parameter in wood modification for measuring the amount of impregnated material that enters the wood. The WPG value is determined by comparing the weight of the modified wood to its initial weight [42]. A higher WPG value indicates a greater amount of impregnated material in the wood. Principally, this modification occurred due to the penetration of the FA or FA-tannin solution into the wood, particularly into the cell lumens, wood cavities, and/or cell walls, where the solution polymerized to form a solid polymer, increasing the initial weight of the wood [30].

The results showed that the WPG values from the impregnation with FA-tannin solutions were lower compared to those obtained with FA solutions without tannin (Fig. 3; each value in Fig. 3 represents the average of five samples). A higher WPG value reflects a more significant modification effect [30].

Figure 3: Weight percent gain of FA and FA-tannin modified wood (values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

Analysis of variance (ANOVA) with 95% confidence revealed that FA and FA-tannin treatments significantly influenced the WPG values. Duncan’s post-hoc test indicated that furfurylation treatments with FA and FA-tannin had significantly different effects. Higher FA concentrations in furfurylated tannins resulted in higher WPG values. For example, the WPG value of FA70TA in this study was higher than that of FA-tannin-impregnated beech wood with an FA53.3% concentration, which had a WPG of 38.4% [30]. FA70 modification increased the weight of gmelina wood by up to 48.79%.

Impregnation of FA into other tropical wood species, particularly from Indonesia, was conducted by Hadi et al. [29], using only FA solution with a concentration of ≥98% and tartaric acid as a catalyst. The wood species used were jabon (Anthocephalus cadamba), sengon (Falcataria moluccana), mangium (Acacia mangium), and pine (Pinus merkusii). Due to variations in anatomical characteristics, the WPG values for jabon, sengon, mangium, and pine were 86.3 ± 6.0; 30.1 ± 3.7; 19.1 ± 4.8; and 15.2 ± 4.9, respectively. Compared to our recent study (Fig. 3), these differences in WPG values can be attributed to various factors, such as wood species and its density, wood size, concentration of the impregnating solution (including the catalyst used), and the impregnation technique applied.

Bulking refers to the increase in wood volume after treatment, which is proportional to the theoretical volume of the added chemical [41]. The bulking value for wood treated with the FA solution was slightly higher than that for wood treated with the FA-tannin solution (Fig. 4; each value in Fig. 4 represents the average of five samples). These bulking values correlated positively with the swelling values observed during the impregnation process. The expansion of wood volume due to swelling from FA penetration into the cell walls creates space for modification, resulting in a proportional increase in wood volume after treatment.

Figure 4: Bulking values of FA and FA-tannin modified wood (values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

The highest bulking value observed in the experiment was 15.29%, occurring in wood samples impregnated with the FA70 solution. Duncan’s test revealed that the bulking effect of FA40 and FA40TA treatments was not significantly different, but both differed significantly from the FA70 and FA70TA treatments. The size of the impregnation molecules plays a crucial role in this process [30]. The retention of the impregnating material in the cell walls causes bulking due to the formation of chemical bonds between the impregnating material and cell wall polymers [43]. During polymerization, FA molecules bind to each other, forming furan homopolymers within the lumina, entangling with the cell walls, and cross-linking with lignin [44,45].

3.5 Physical Properties of Modified Gmelina Wood

Moisture content refers to the amount of water in lignocellulosic material. Wood modified with furfuryl alcohol has been shown to lower its equilibrium moisture content [46]. The results indicate that both furfurylation and tannin-modified furfurylation treatments can reduce water content by more than 75% (Fig. 5; each value in Fig. 5 represents the average of five samples).

Figure 5: Moisture content of FA and FA-tannin modified wood (values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

Analysis of variance (ANOVA) with a 95% confidence interval demonstrated that FA and FA-tannin treatments significantly affected the reduction in wood moisture content. Gérardin [4] confirmed that furfurylation can lower the equilibrium moisture content of wood. These findings align with Mulyosari’s research [47], which reported that furfurylation reduced the water content of Sengon wood to 2.57%–3.75%. Furfuryl alcohol is hydrophobic due to the formation of methylene bridges and covalent bonds between FA and the aromatic groups in lignin, which cover the hydroxyl and hydrophilic groups of the wood [44,45].

Among the modified woods, the FA40TA treatment showed significantly higher moisture content compared to other treatments. This could be attributed to the lower weight percent gain (WPG) of FA40TA, which limits the extent of wood modification and affects moisture content. The higher amount of tannins, with their larger molecular weight and some unreacted hydroxyl groups, combined with the lower FA concentration, likely reduced the hydrophobic properties of the furfurylated wood.

Compared to a previous similar study on the impregnation of tropical wood species using only FA solution (≥98%) and tartaric acid as a catalyst, the moisture content of furfurylated jabon, sengon, mangium, and pine was 2.11 ± 0.34%, 2.65 ± 0.36%, 3.75 ± 0.44%, and 3.16 ± 0.34%, respectively [29]. These moisture content values are similar to those in the recent study (Fig. 5), indicating that furfurylation can effectively reduce the hygroscopic properties of wood, regardless of the wood species used.

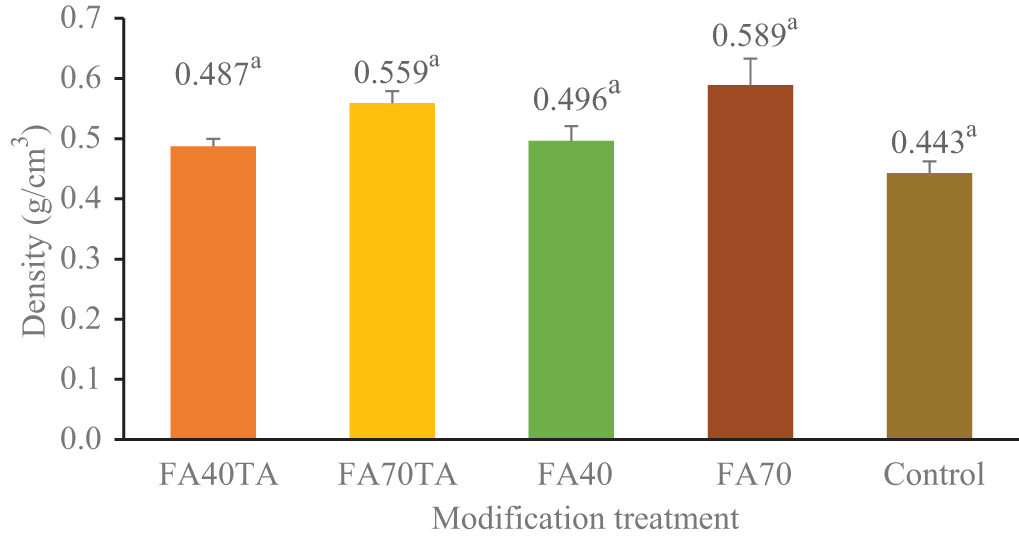

Wood density, defined as the ratio of wood mass to volume and expressed in g/cm³, increased after modification with FA and FA-tannin (Fig. 6; each value in Fig. 6 represents the average of five samples). This increase in density was positively correlated with higher WPG and bulking values. Wood density rose by approximately 9% to 30% due to these modifications. The increases in density were attributed to the higher WPG and lower bulking values, indicating that FA or FA-tannin were deposited in the wood lumen cells or cavities and formed deposits and cross-links with certain wood components in the cell walls. Among the treatments, FA70 resulted in the highest average density, reaching approximately 0.59 g/cm3.

Figure 6: Density of FA and FA-tannin modified wood (values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

The results of the variance analysis (ANOVA) with a 95% confidence interval showed that wood modification treatment using FA and FA-tannin significantly increased the density value. The greater the FA concentration used, the more substantial the increase in density.

Furfurylation with high FA concentration (>98%) of tropical woods, jabon, sengon, mangium, and pine, can increase their density by up to 88.2%, 27.8%, 21.7%, and 15.3%, respectively [29]. The variation in density increase appears to be influenced by the wood species used and the corresponding WPG obtained. In a recent study, gmelina wood density increased by 12% and 33% after impregnation with 40% and 70% FA, respectively.

Dimensional change testing was conducted to assess the stability of modified gmelina wood by measuring changes in dimensions after soaking in water for 24, 48 h, and 14 days. The results showed that wood modified with either FA or FA-tannin solutions exhibited significantly greater dimensional stability, by up to 12.4% differences in dimensional change, compared to the control wood (Fig. 7; each value in Fig. 7 represents the average of five samples). While most dimensional changes in the modified wood were not significantly different due to higher standard deviations, wood modified with FA70 and FA70TA generally exhibited lower dimensional changes than other treatments. These variations may be attributed to differences in the anatomical structure of the wood. The higher WPG values for wood modified with FA70 and FA70TA contributed to lower dimensional changes, providing greater hydrophobic properties and limiting expansion.

Figure 7: Dimensional changes of FA and FA-tannin modified wood after soaking (values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

Between the two impregnation solutions, wood modified with FA70TA demonstrated slightly better dimensional stability, by up to 1.19% differences in dimensional change value, than wood modified with FA70, particularly after 48 h and 14 days of soaking. Although both FA70TA and FA70 treatments did not show significant differences, Mubarok et al. [30] also reported that FA-tannin modification offered slightly better dimensional stability compared to FA alone, especially with a carboxylic acid catalyst of lower dissociation constant.

In contrast, wood samples impregnated with the FA40 solution exhibited slightly lower dimensional stability (i.e., higher dimensional changes) after 24 and 48 h of soaking compared to FA70 modified wood. This suggests that impregnation with high FA consentration values provided higher dimensional stability due to greater FA retention, which resulted in higher bulking values and improved dimensional stability.

Regarding dimensional changes, Hadi et al. [29] found that furfurylation (FA > 98%) of tropical woods, jabon, sengon, mangium, and pine, resulted in dimensional change values of up to 1.38 ± 0.20%, 2.38 ± 0.19%, 2.63 ± 0.32%, and 4.21 ± 0.51%, respectively. These values seem slightly higher than those obtained in our recent study (Fig. 7), despite the longer immersion duration used in our tests. The wood species and the WPG achieved through this modification were likely the main factors behind these differences.

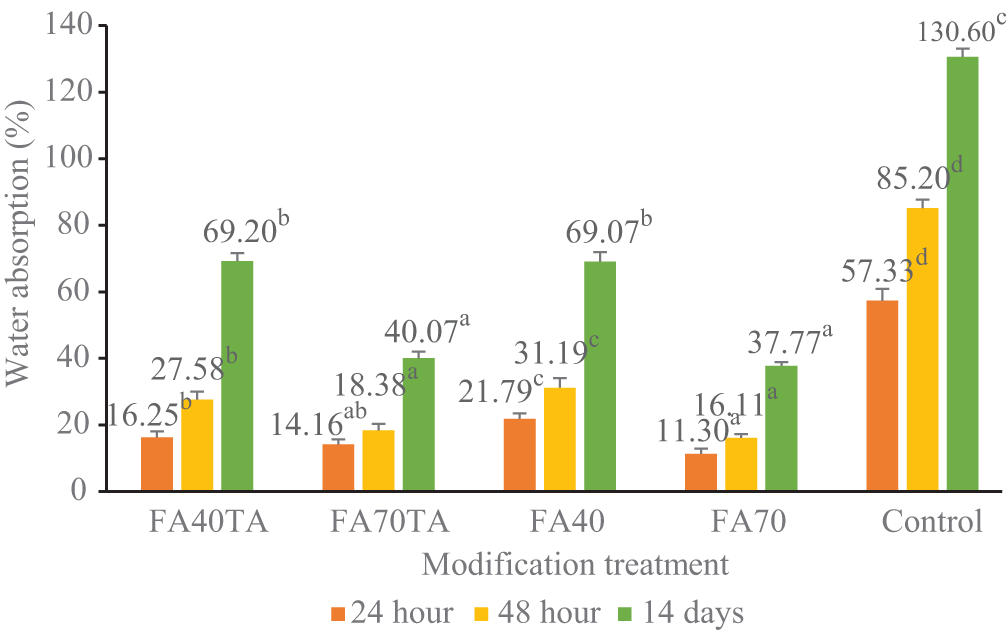

Water absorption measures the percentage of water absorbed by the wood relative to its weight. This study aimed to assess the hydrophobic properties of the modified wood by soaking samples in water for 24, 48 h, and 14 days. Since dimensional stability is influenced by the wood’s water absorption capacity, higher hydrophobicity generally correlates with greater dimensional stability.

Analysis of variance (ANOVA) with a 95% confidence interval revealed that both FA and FA-tannin treatments significantly reduced water absorption (Fig. 8; each value in Fig. 8 represents the average of five samples). Among the treatments, wood impregnated with FA alone typically exhibited lower water absorption, by up to 5.54% differences, than wood treated with FA-tannin solutions. However, differences between the FA70 and FA70TA treatments were not significant. The FA70 treatment resulted in the lowest water absorption capacity, indicating that it produced wood with better hydrophobic properties and, consequently, higher dimensional stability. This is likely due to the higher polarity of tannins, which contain hydroxyl groups that limit FA’s ability to modify the wood cell walls by creating a stronger affinity between FA and tannins.

Figure 8: Water absorption of FA and FA-tannin modified wood (values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

In contrast, Mubarok et al. [30] reported that FA-tannin treatments resulted in lower water absorption compared to FA treatments, regardless of the carboxylic acid catalyst’s dissociation constant. The discrepancy may stem from differences in tannin types and wood species used. Mubarok et al. [30] employed Tan Active powder extract, a condensed tannin from quebracho, while this study used tannin extracted from mahogany bark, which may still contain carbohydrate residues. These residual carbohydrates could contribute to higher hygroscopic properties in the rough tannin extract, affecting the characteristics of the modified wood. Additionally, Lestari et al. [48] identified mahogany bark tannins as hydrolyzable tannins containing gallic acid and ellagic acid, which may also influence the results.

In a previous study, furfurylation using high FA concentrations (>98%) on tropical woods, jabon, sengon, mangium, and pine, resulted in water absorption values after 48 h of immersion of up to 5.85 ± 0.64%, 6.57 ± 0.63%, 7.63 ± 0.69%, and 10.65 ± 1.02%, respectively [29]. In the recent study, since the FA concentrations used were only 40% and 70%, the water absorption values were higher than in the previous study. The wood species and the corresponding WPG were likely the main reasons for these differences.

3.5.5 Anti-Swelling Efficiency

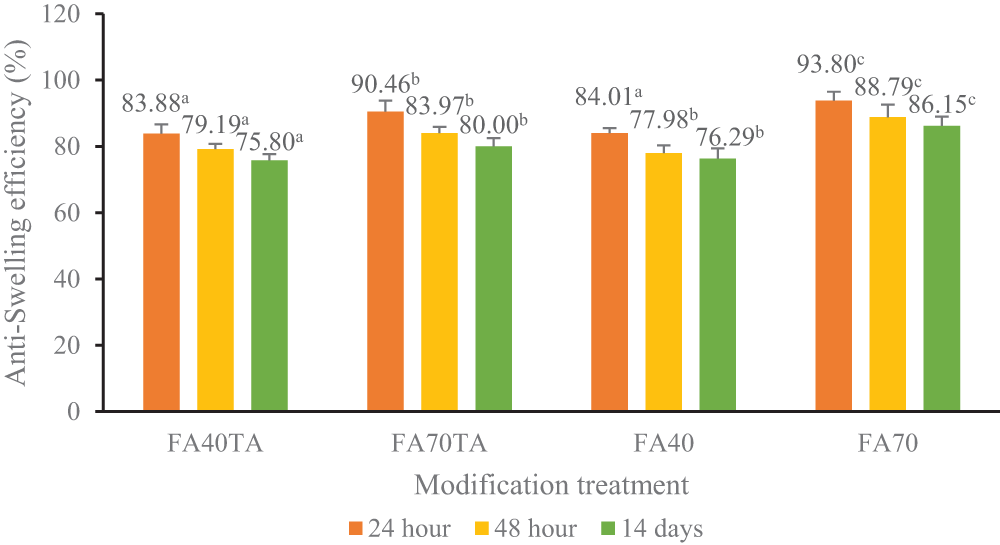

Anti-swelling efficiency (ASE) measures the effectiveness of wood modification in terms of its water resistance [49]. ASE is calculated based on the previously discussed dimensional change values. A high ASE value indicates that the wood is more resistant to swelling from water absorption, reflecting good dimensional stability. In this study, the average ASE values ranged from 75.80% to 93.80%, demonstrating excellent dimensional stability in the modified gmelina wood (Fig. 9; each value in Fig. 9 represents the average of five samples).

Figure 9: Anti-swelling efficiency of FA and FA-tannin modified wood (values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

ANOVA with a 95% confidence interval showed that FA and FA-tannin treatments significantly influenced the ASE values of the modified wood. Duncan’s test revealed that the ASE values for FA40TA and FA40 treatments were not significantly different, although FA40TA tended to have slightly lower ASE values, by up to 1.21% differences, compared to FA40. The lower ASE values in these treatments could be attributed to the relatively lower FA concentrations, which corresponded to lower WPG values. Specifically, the FA-tannin treatment required more FA to react with both the tannins and wood cell wall components, which may have limited the hydrophobic properties and, consequently, the stability of the modified wood. FA modification and FA-tannin can fill the cell walls of wood and even reach cell lumen which causes the density of the wood to increase so that it has good dimensional stability [30].

With regard to the previous dimensional change values, impregnation of tropical woods using high FA concentrations provided furfurylated jabon, sengon, mangium, and pine with varied ASE values after 48 h of water immersion, reaching up to 82.7 ± 2.7, 70.0 ± 4.4, 76.2 ± 2.1, and 56.7 ± 5.3, respectively [29]. In the recent study, furfurylation of gmelina wood with 40% and 70% FA achieved ASE values of over 75% after 14 days of water immersion. The wood species and the corresponding WPG were also likely the main reasons for these differences.

According to Lebow et al. [50], wood leaching tests are used to assess the fixation of preservatives, their environmental impact, and the estimated service life of the wood. A higher amount of leached components indicates reduced wood durability and potential environmental pollution from water-soluble chemicals. Pilgard et al. [51] found that furfurylated wood subjected to vacuum drying produced fewer hydrophobic oligomers, resulting in lower toxicity compared to furfurylated wood without vacuum drying. Since this study’s furfurylation process did not include vacuum drying, the addition of tannins was anticipated to interact with any unreacted FA during polymerization, potentially reducing the toxicity of the furfurylated wood.

The results (Fig. 10; each value in Fig. 10 is based on the average of five samples) showed that the leaching value of furfurylated wood was lower than that of the control wood. In control wood, water-extractive substances are dissolved during water soaking [30]. ANOVA results with a 95% confidence interval indicated that furfuryl alcohol treatments (FA40 and FA70) and FA-tannin treatments (FA40TA and FA70TA) significantly affected the leaching of modified gmelina wood. Duncan’s tests revealed significant differences between the leaching values for various treatments. The lower leaching value in furfurylated wood suggests that FA reacted with the wood, particularly with lignin [4,44,45]. FA40TA showed higher leaching compared to FA70TA, likely due to lower tannin reactivity with the wood. Lagel et al. [52] noted that a higher tannin ratio relative to the impregnation solution only slightly improved wood properties, including leaching resistance. Therefore, the higher tannin ratio in the FA40TA treatment compared to FA70TA could have increased the wood’s hydrophilic properties and leaching values. This contrasts with Mubarok et al. [30], which found that adding 8.9% tannin to a 44% FA in furfurylation system improved leaching resistance. Differences in tannin types, wood species, and organic acid catalysts used (carboxylic acid) might account for these discrepancies. However, at a higher FA concentration (70%), adding 0.6% tannin increased leaching resistance by approximately 47% compared to FA70 without tannins.

Figure 10: Leaching of FA and FA-tannin modified wood (values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

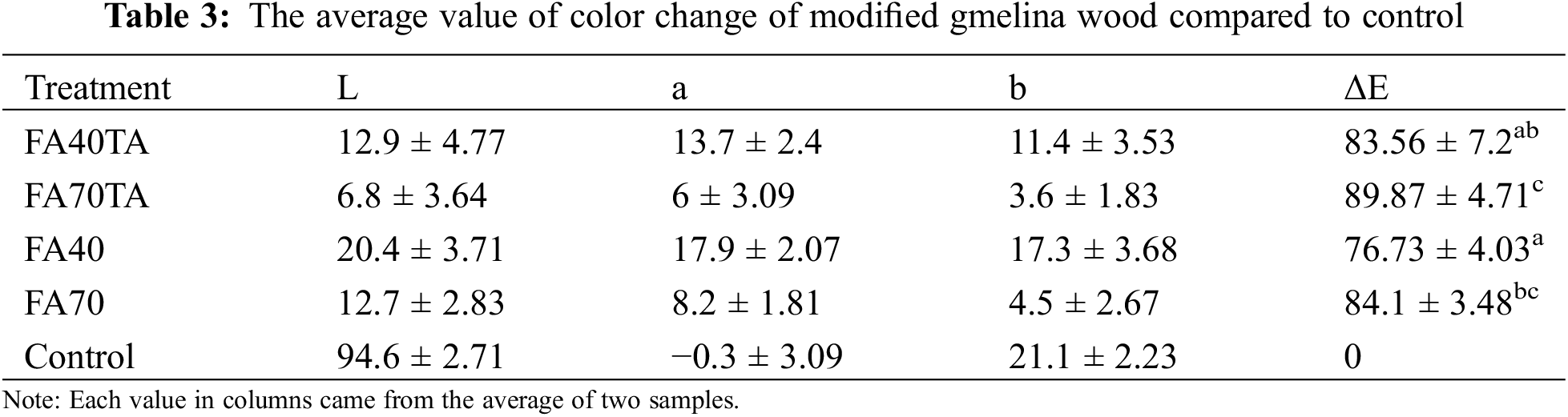

Color is an important aesthetic property of wood. According to Lukmandaru et al. [53], the color of wood is crucial for determining its suitability for specific applications in furniture or construction materials. Modification of Gmelina wood with either FA or FA-tannin resulted in a color change from the original yellowish-white to dark brown (Fig. 11).

Figure 11: Appearance of FA40TA, FA70TA, control, FA40, and FA7 (from the left to right)

ANOVA results with a 95% confidence interval indicated that both FA and FA-tannin modifications significantly affected the color change of the wood (Table 3). The color change values were classified as class 6, with ∆E > 12 (Table 2). Furfuryl alcohol, initially transparent or pale yellow, turns brown to dark brown with prolonged exposure to sunlight or air [54]. In this study, the polymer formed was polyfurfuryl alcohol (PFA), which is dark in color [10,30]. Consequently, wood modified using this method appears darker. The addition of tannins, which are also dark, further intensifies the color, resulting in a wood that is darker than wood treated with FA alone. Despite this, the darker color may be desirable as it mimics the appearance of aged wood, potentially enhancing its perceived physical and mechanical properties and improving resistance to wood-destroying organisms.

For interior applications, compatible finishing materials are important because they can mitigate potential issues such as unreacted FA leaching and reduce any characteristic odor. The inclusion of tannins in the furfurylation process helps capture unreacted FA and reduce its leaching properties, thereby minimizing air pollution during FA polymerization.

Compared to a previous similar study, impregnation with higher FA concentrations in jabon, sengon, mangium, and pine produced furfurylated wood with lower ΔE values, reaching up to 58.1 ± 3.6% 56.1 ± 2.1, 32.9 ± 5.9, and 52.9 ± 3.7, respectively [29]. Our recent study observed higher ΔE values (Table 3), with L values lower than 20, indicating a darker color. The wood species and the corresponding WPG values were also important factors influencing these results.

3.6 Mechanical Properties of Modified Gmelina Wood

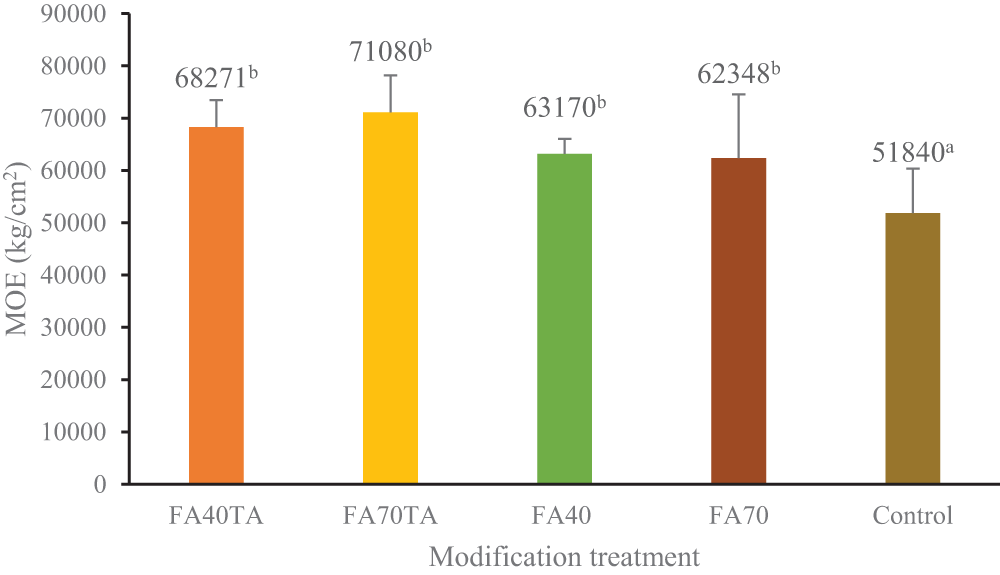

The modulus of elasticity (MOE) measures the flexibility of wood, reflecting its resistance to shape changes under external loads. A higher MOE indicates that the wood is less likely to deform under stress, with a greater MOE value signifying greater resistance to shape changes.

The results showed that wood samples impregnated with either the FA solution or the FA-tannin solution exhibited higher MOE values compared to the control wood (Fig. 12; each value in Fig. 12 was based on the average of five samples). Analysis of variance (ANOVA) with a 95% confidence level revealed that the wood modification using FA significantly impacted the MOE values. Among the treatments, wood modified with FA-tannin solutions had higher MOE values, by up to 8732 kg/cm2 differences, than wood treated with FA alone. This improvement is likely due to the formation of FA-tannin polymer composites within the wood cells or cavities. The FA-tannin interaction, occurring in the same liquid phase, may have reduced the reaction between FA and wood components, particularly lignin, which binds plant fibers [55]. By minimizing the reaction between FA and lignin, the structural integrity of the wood is better maintained, thus preserving its mechanical properties.

Figure 12: Modulus of elasticity of FA and FA-tannin modified wood (values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

Additionally, impregnation with furfuryl alcohol may disrupt the hydrogen bonding between fibers in the wood [56]. The inclusion of tannins in the FA treatment likely helps mitigate the degradation of mechanical properties. However, Duncan’s test indicated no significant difference in MOE values between the FA and FA-tannin treatments. This finding aligns with Mubarok et al. [30], who also found no significant difference in MOE values between FA and FA-tannin treatments, though variations in tannin types and concentrations were noted. Dong et al. [57] and Li et al. [58] similarly reported that FA impregnation did not significantly affect MOE values.

Regarding the MOE values, tropical woods such as jabon, sengon, mangium, and pine modified with a high concentration of FA (>98%) showed increased MOE values, with the average increases of 2.66%, 19.93%, 37.86%, and 0.19%, respectively [29]. In the current study, the MOE values of wood modified with FA at concentrations of 40% and 70% increased by 20.27% and 21.84%, respectively. Additionally, adding tannin to the FA 40% and FA 70% solutions resulted in furfurylated gmelina with MOE increases of 31.7% and 37.11%, respectively. Differences in wood species, wood size, and corresponding WPG values may also be primary factors contributing to these variations.

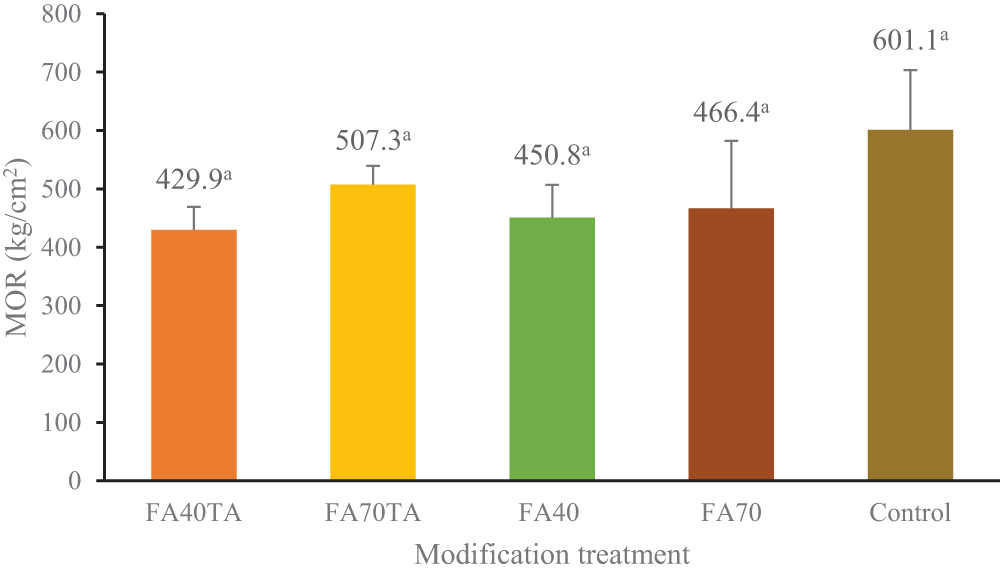

The modulus of rupture (MOR) represents the maximum load that wood can withstand before breaking. In this study, wood impregnated with either the FA solution or the FA-tannin solution exhibited lower MOR values compared to the control wood (Fig. 13; each value in Fig. 13 was based on the average of five samples). Lower MOR values are a common issue in modified wood, whether subjected to thermal treatments or chemical modifications [4,56,59]. This decrease in MOR is primarily due to changes in the chemical structure of the wood, which affect its strength and toughness.

Figure 13: Modulus of rupture of FA and FA-tannin modified wood compared to control wood (Values followed by the same letter do not differ significantly based on ANOVA at α = 0.05 using Duncan’s post-hoc test)

Analysis of variance (ANOVA) with a 95% confidence interval revealed that furfurylation using FA and FA-tannin did not significantly impact the MOR values. These findings are consistent with Mubarok et al. [30], who observed a reduction in MOR values for wood modified with FA or FA-tannins compared to the control, although the changes were not statistically significant. Ihsan [60] noted that cross-linking of FA with lignin might make the wood more prone to breakage. Similarly, Dong et al. [57] reported that while furfuryl alcohol can enhance certain properties of wood, it does not improve strength and impact flexural strength. Therefore, further research is needed to explore ways to enhance the mechanical properties of modified wood.

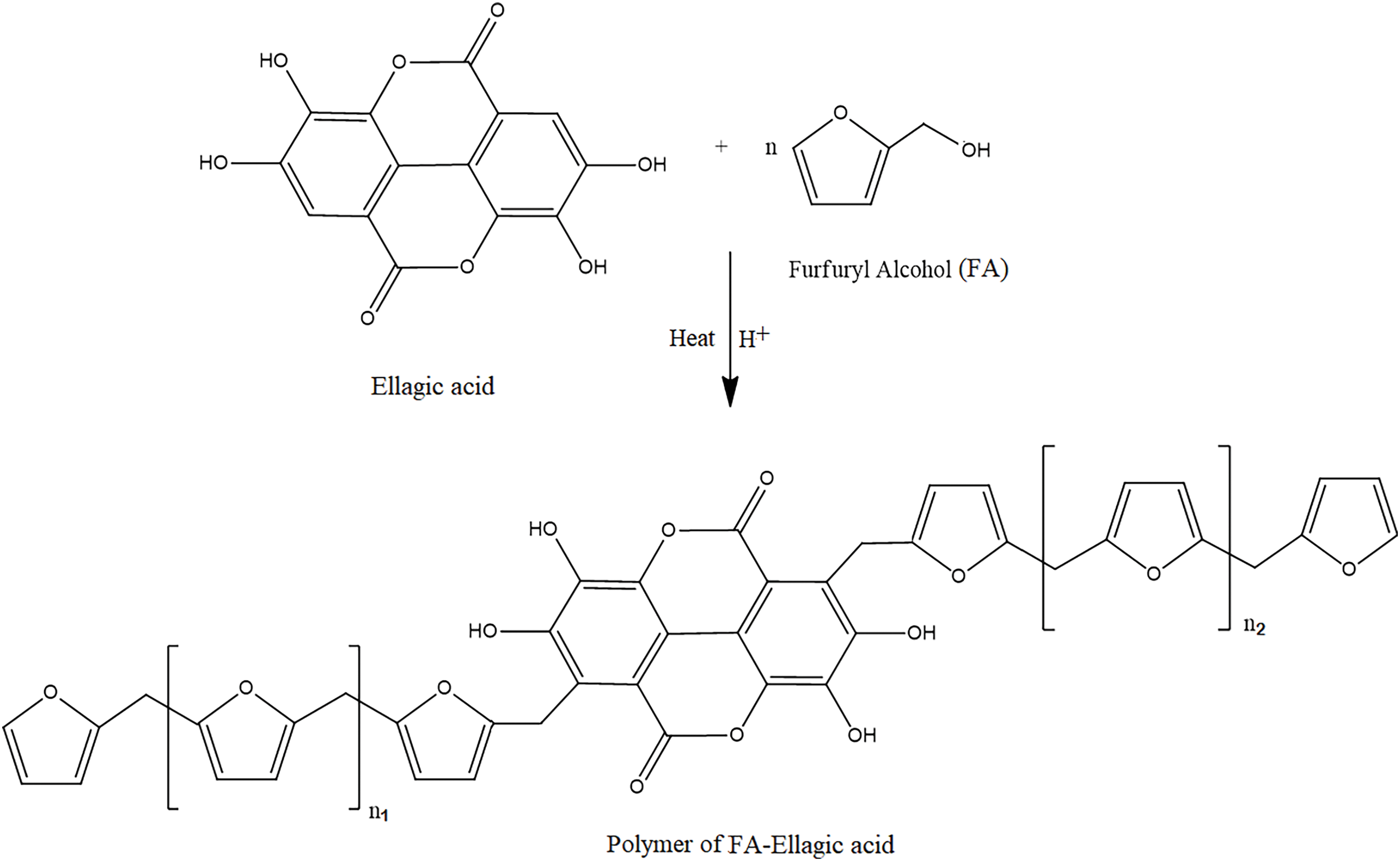

The changes in the physical and mechanical properties of gmelina wood, whether comparing FA-tannin with the control or FA-tannin with FA treatments, were attributed to chemical reactions occurring within the wood structure. The in situ polymerization between FA and wood components, specifically lignin in this case, was demonstrated in some previous research [44,45]. Additionally, a possible cross-linking reaction between condensed tannins from quebracho tannin and FA was suggested by Mubarok et al. [30]. However, since the tannin used in this study was hydrolyzable tannin derived from mahogany bark, a possible reaction between FA and tannin in this study is illustrated in Fig. 14.

Figure 14: A possible reaction between furfuryl alcohol and a component of hydrolyzable tannin from mahagony bark

Unlike MOE, almost all furfurylated wood showed lower MOR values. Furfurylation with a high FA concentration (>98%) in jabon, sengon, mangium, and pine resulted in MOR changes of −36.16%, 0.88%, 58.20%, and −13.48%, respectively [29]. In the current study, MOR changes ranged from −22.46% to −25.12% for wood impregnated with FA alone (Fig. 13). Adding tannin to FA 70% reduced MOR changes to −15.64%, suggesting that wood modification with FA-tannin can help minimize MOR degradation.

Wood modification using furfuryl alcohol (FA) and FA-tannin has proven to significantly enhance the physical and mechanical properties of Gmelina wood. The incorporation of tannins during the impregnation process slightly reduced solution uptake and swelling values, reflecting its influence on the modification dynamics. While the presence of tannins led to minor reductions in weight percent gain (3.30%–4.86%) and bulking effect (0.37%–0.65%), it did not compromise performance. Remarkably, FA-tannin treatments exhibited comparable anti-swelling efficiency to FA alone, with tannins improving the leaching resistance of furfurylated wood by up to 47% at a 70% FA concentration, making the product more environmentally sustainable.

Color analysis revealed that the tannin solution imparted a darker hue to the furfurylated wood, offering aesthetic appeal alongside enhanced performance. Mechanically, the addition of tannins increased the modulus of elasticity by up to 37.11%, while the modulus of rupture showed only a slight and statistically insignificant decrease, consistent with observations in other modified wood studies.

Despite these promising outcomes, the adoption of furfurylated wood in Indonesia faces challenges, particularly due to the still high cost of the main material, furfuryl alcohol. Addressing these challenges will require continued research and innovation, such as the integration of tannins demonstrated in this study, to optimize the efficiency and cost-effectiveness of the modification process. Furthermore, fostering stronger collaboration between researchers and industry stakeholders will be pivotal in driving broader adoption and realizing the full potential of this technology in sustainable wood products.

Acknowledgement: The authors would like to express their appreciation to the Directorate General of Higher Education, Research, and Technology, Ministry of Education, Culture, Research, and Technology, which sponsored the research grant via the National Competitive Basic Research Scheme. The authors also thank IPB University (Bogor Agricultural University), the Center for Standardization of Sustainable Forest Management Instruments (Ministry of Environment and Forestry), and the Research Center for Biomass and Bioproducts (National Research and Innovation Agency (BRIN)), all in Bogor, Indonesia, for the use of their research facilities.

Funding Statement: This research was funded by the Directorate General of Higher Education, Research, and Technology, Ministry of Education, Culture, Research, and Technology, Indonesia, which sponsored the research grant via the National Competitive Basic Research Scheme, No. 027/E5/PG.02.00.PL/2024, facilitated by IPB University (Bogor Agricultural University) through Research Contract No. 22055/IT3. D10/PT.01.03/P/B/2024. The research was also funded by Research Organization for Nanotechnology and Materials No. 3/III.10/HK/2023, National Research and Innovation Agency (BRIN), Indonesia.

Author Contributions: Conceptualization, Mahdi Mubarok, Philippe Gérardin, Dede Hermawan, Trisna Priadi, and Wayan Darmawan; methodology, Mahdi Mubarok, Philippe Gérardin, Jingjing Liao, Adi Santoso, and Yusuf Sudo Hadi; software, Imam Busyra Abdillah, Adik Bahanawan, Rohmah Pari, and Mahdi Mubarok; validation, Saefudin, Efrida Basri, and Mahdi Mubarok; formal analysis, Pirda Maharani Nafisah, Adi Santoso, Adik Bahanawan, and Mahdi Mubarok; investigation, Pirda Maharani Nafisah, Rohmah Pari, Imam Busyra Abdillah, and Mahdi Mubarok; resources, Saefudin, Efrida Basri, and Mahdi Mubarok; data curation, Pirda Maharani Nafisah, Jingjing Liao, Rohmah Pari, and Mahdi Mubarok; writing original draft preparation, Mahdi Mubarok, Pirda Maharani Nafisah, and Imam Busyra Abdillah; writing review and editing, Mahdi Mubarok, and Pirda Maharani Nafisah; visualization, Yusuf Sudo Hadi, Dede Hermawan, Wayan Darmawan, Philippe Gérardin, and Trisna Priadi; supervision, Philippe Gérardin; project administration, Imam Busyra Abdillah, Wayan Darmawan, Trisna Priadi, and Dede Hermawan; funding acquisition, Mahdi Mubarok, and Saefudin. All authors reviewed the results and approved the final version of the manuscript..

Availability of Data and Materials: Not applicable.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Ministry of Forestry and Environment (KLHK). Indonesian forestry statistics. Jakarta: Ministry of Forestry and Environment; 2021. [Google Scholar]

2. Ministry of Forestry and Environment (KLHK). Indonesian forestry statistics. Jakarta: Ministry of Forestry and Environment; 2023. [Google Scholar]

3. Ministry of Forestry and Environment (KLHK). Indonesian forestry statistics. Jakarta: Ministry of Forestry and Environment; 2024. [Google Scholar]

4. Gérardin P. New alternatives for wood preservation based on thermal and chemical modification of wood—a review. Ann For Sci. 2016;73(3):559–70. doi:10.1007/s13595-015-0531-4. [Google Scholar] [CrossRef]

5. Boonstra MJ, Van Acker J, Tjeerdsma BF, Kegel EV. Strength properties of thermally modified softwoods and its relation to polymeric structural wood constituents. Ann For Sci. 2007;64:679–90. [Google Scholar]

6. Hasanagić R, Ganguly S, Bajramović E, Hasanagić A. Mechanical properties changes in fir wood (Abies sp.linden wood (Tilia sp.and beech wood (Fagus sp.) subjected to various thermal modification process conditions. IOP Conf Ser Mater Sci Eng. 2021;1208:012025. doi:10.1088/1757-899X/1208/1/012025. [Google Scholar] [CrossRef]

7. Hasanagić R, Fathi L, Hodžić A, Bahmani M. Physical and mechanical changes in thermal modified wood: a review. Zast Mater. 2023;64(3):314–26. doi:10.5937/zasmat2303314H. [Google Scholar] [CrossRef]

8. Yue K, Qian J, Wu P, Jiao X, Lu D, Song X. Experimental analysis of thermally-treated Chinese poplar wood with focus on structural application. Ind Crops Prods. 2023;197:116612. [Google Scholar]

9. Hill C, Altgen M, Rautkari L. Thermal modification of wood—a review: chemical changes and hygroscopicity. J Mater Sci. 2021;56(11):6581–614. doi:10.1007/s10853-020-05722-z. [Google Scholar] [CrossRef]

10. Zelinka SL, Altgen M, Emmerich L, Guigo N, Keplinger T, Kymalainen M, et al. Review of wood modification and wood functionalization technologies. Forests. 2022;13(7):1–46. doi:10.3390/f13071004. [Google Scholar] [CrossRef]

11. Scheiding W, Ala-Viikari J, Tetri T. Thermal wood modification after 20 years of commercialization: an overview and the thermowood® story. In: Proceedings of the 10th European Conference on Wood Modification (ECWMProuvé Congress Centre, 2022 Apr 25–26; Nancy, France. [Google Scholar]

12. Cao S, Cheng S, Cai J. Research progress and prospects of wood high-temperature heat treatment technology. BioResources. 2022;17(2):3702–17. doi:10.15376/biores.17.2.Cao. [Google Scholar] [CrossRef]

13. Dong Y, Wang K, Li J, Zhang S, Shi QS. Environmentally benign wood modifications: a review. ACS Sustain Chem Eng. 2020a;8(9):3532–40. doi:10.1021/acssuschemeng.0c00342. [Google Scholar] [CrossRef]

14. Liao J, Mubarok M. Revolutionizing wood: cutting-edge modifications, functional wood-based composites, and innovative applications in wood industry—impacts and benefits. London, UK: IntechOpen; 2024. [Google Scholar]

15. Beck G. Leachability and decay resistance of wood polyesterified with sorbitol and citric acid. Forests. 2020;11(6):650. doi:10.3390/f11060650. [Google Scholar] [CrossRef]

16. Mubarok M, Militz H, Dumarçay S, Gérardin P. Beech wood modification based on in situ esterification with sorbitol and citric acid. Wood Sci Technol. 2020a;54(3):479–502. doi:10.1007/s00226-020-01172-7. [Google Scholar] [CrossRef]

17. Kurkowiak K, Emmerich L, Militz H. Wood chemical modification based on bio-based polycarboxylic acid and polyols–status quo and future perspectives. Wood Mater Sci Eng. 2021a;17(6):1040–54. doi:10.1080/17480272.2021.1925961. [Google Scholar] [CrossRef]

18. Kurkowiak K, Emmerich L, Militz H. Sorption behavior and swelling of citric acid and sorbitol (SorCA) treated wood. Holzforschung. 2021b;75(12):1136–49. doi:10.1515/hf-2021-0068. [Google Scholar] [CrossRef]

19. Chabert AJ, Fredon E, Rémond R. Improving the stability of beech wood with polyester treatment based on malic acid. Holzforschung. 2022;76(3):268–75. doi:10.1515/hf-2021-0030. [Google Scholar] [CrossRef]

20. Ermeydan MA, Babacan M, Tomak ED. Evaluation of dimensional stability, weathering and decay resistance of modified pine wood by in-situ polymerization of styrene. J Wood Chem Technol. 2020;40(5):294–305. doi:10.1080/02773813.2020.1786127. [Google Scholar] [CrossRef]

21. Jambreković B, Govorčin BE, Španić N, Sedlar T, Sinković T. Viscoelastic and thermal properties of styrene modified fir wood. Polymers. 2022;14(4):786. doi:10.3390/polym14040786. [Google Scholar] [PubMed] [CrossRef]

22. Uyup MA, Sahari S, Jalaludin Z, Husain H, Lee S, Yusoh A. Water vapour sorption behaviour and physico-mechanical properties of methyl methacrylate (MMA)- and MMA-styrene-modified batai (Paraserianthes falcataria) wood. Holzforschung. 2021;75(5):444–51. doi:10.1515/hf-2020-0005. [Google Scholar] [CrossRef]

23. Dong Y, Altgen M, Mäkelä M, Rautkari L, Hughes M, Li J, et al. Improvement of interfacial interaction in impregnated wood via grafting methyl methacrylate onto wood cell walls. Holzforschung. 2020b;74(10):967–77. doi:10.1515/hf-2019-0144. [Google Scholar] [CrossRef]

24. Acosta AP, Labidi J, Schulz HR, Gallio E, Barbosa KT, Beltrame R, et al. Thermochemical and mechanical properties of pine wood treated by in situ polymerization of methyl methacrylate (MMA). Forests. 2020;11(7):768. doi:10.3390/f11070768. [Google Scholar] [CrossRef]

25. Sejati PS, Imbert A, Charbonnier CG, Dumarçay S, Fredon E, Masson E, et al. Tartaric acid catalyzed durfurylation of beech wood. Wood Sci Technol. 2017;51(2):379–94. [Google Scholar]

26. Li W, Liu M, Wang H, Yu Y. Fabrication of highly stable and durable furfurylated wood materials. Part I: process optimization. Holzforschung. 2020a;74(12):1135–46. doi:10.1515/hf-2019-0286. [Google Scholar] [CrossRef]

27. Li W, Liu M, Wang H, Yu Y. Fabrication of highly stable and durable furfurylated wood materials. Part II: the multi-scale distribution of furfuryl alcohol (FA) resin in wood. Holzforschung. 2020b;74(12):1147–55. doi:10.1515/hf-2019-0287. [Google Scholar] [CrossRef]

28. Martin LS, Jelavić S, Cragg SM, Thygesen LG. Furfurylation protects timber from degradation by marine wood boring crustaceans. Green Chem. 2021;23(20):8003–15. doi:10.1039/D1GC01524A. [Google Scholar] [CrossRef]

29. Hadi YS, Herliayana EN, Pari G, Pari R, Abdillah IB. Furfurylation effects on discoloration and physical-mechanical properties of wood from tropical plantation forests. J Korean Wood Sci Technol. 2022;50(1):46–58. doi:10.5658/WOOD.2022.50.1.46. [Google Scholar] [CrossRef]

30. Mubarok M, Charbonnier GC, Azadeh E, Akong FO, Dumarcay S, Pizzi A, et al. Modification of wood by tannin-furfuryl alcohol resins-effect on dimensional stability, mechanical properties and decay durability. J Renew Mater. 2022;11(2):505–21. doi:10.32604/jrm.2022.024872. [Google Scholar] [CrossRef]

31. Santoso A, Abdurachman. Karakteristik ekstrak kulit kayu mahoni sebagai perekat kayu. Jurnal Penelitian Hasil Hutan. 2016;34(4):269–84. doi:10.20886/jphh.2016.34.4.269-284. [Google Scholar] [CrossRef]

32. DIN 52186 Testing of wood. Bending test. Berlin: German Institute for Standardisation (Deutsches Institut für Normung); 1978. [Google Scholar]

33. British Standard. Methods of testing small clear specimens of timber. BS 373. London: British Standards Institution; 1957. [Google Scholar]

34. EN 84. Wood preservatives—accelerated ageing of treated wood prior to biological testing. In: Leaching procedure. Brussels: European Committee for Standardization (CEN); 1997. [Google Scholar]

35. Christie RM. Colour chemistry. Cambridge, UK: The Royal Society of Chemistry Science Park; 2007. [Google Scholar]

36. Hunter Lab. CIE L*a*b* color scale. Application Note. 1996;8:1–4. [Google Scholar]

37. Archer K, Lebow S. Wood preservation. Winconsin, USA: CRC Press; 2006. [Google Scholar]

38. Prabawa SB. Pengaruh posisi pada batang terhadap sifat fisik dan dimensi serat kayu gmelina hasil penjarangan. Jurnal Ilmu Teknologi Kayu Tropis. 2017;15:19–28 (In Indonesian). [Google Scholar]

39. Furuno T, Imamura Y, Kajita H. The modification of wood by treatment with low molecular weight phenol-formaldehyde resin: a properties enhancement with neutralized phenolic-resin and resin penetration into wood cell walls. Wood Sci Technol. 2004;37(5):349–61. doi:10.1007/s00226-003-0176-6. [Google Scholar] [CrossRef]

40. Das AK, Islam N, Faruk O, Ashaduzzaman, Dungani R. Review on tannins: extraction processes, applications and possibilities. S Afr J Bot. 2020;135(6):58–70. doi:10.1016/j.sajb.2020.08.008. [Google Scholar] [CrossRef]

41. Augustina S, Dwianto W, Wahyudi I, Syafii W, Gerardin P, Marbun SD. Wood impregnation in relation to its mechanisms and properties enhancement. BioResources. 2023;18(2):4332–72. doi:10.15376/biores.18.2.augustina. [Google Scholar] [CrossRef]

42. Rowell R. Handbook of wood chemistry and wood composites. 2nd ed. Boca Raton, FL, USA: CRC Press; 2012. [Google Scholar]

43. Xu X. Wood modification with resin impregnation technology for value-added services. Svoa Mater Sci Technol. 2020;2(1):9–21. [Google Scholar]

44. Shen X, Guo D, Jiang P, Li G, Yang S, Chu F. Reaction mechanisms of furfuryl alcohol polymer with wood cell wall components. Holzforschun. 2021a;75(12):1150–8. doi:10.1515/hf-2020-0271. [Google Scholar] [CrossRef]

45. Xu J, Hu D, Zheng Q, Meng Q, Li N. The distribution and polymerization mechanism of polyfurfuryl alcohol (PFA) with lignin in furfurylated wood. Polymers. 2022;14(6):1071. doi:10.3390/polym14061071. [Google Scholar] [PubMed] [CrossRef]

46. Shen X, Guo D, Jiang P, Yang S, Li G, Chu F. Water vapor sorption mechanism of furfurylated wood. J Mater Sci. 2021b;56(19):11324–34. doi:10.1007/s10853-021-06041-7. [Google Scholar] [CrossRef]

47. Mulyosari D. Sifat fisis dan mekanis kayu sengon (Falcataria moluccana Miq.) dan kayu mangium (Acacia mangium Willd.) terimpregnasi furfuril alkohol (Thesis). Institut Pertanian Bogor: Bogor, Indonesia; 2020 (In Indonesian). [Google Scholar]

48. Lestari ASRD, Hadi YS, Hermawan D, Santoso A, Pizzi A. Physical and mechanical properties of glued-laminatedlumber from fast-growing tree species using mahoganytannin adhesive. Wood Fiber Sci. 2019;51(2):132–43. doi:10.22382/wfs-2019-015. [Google Scholar] [CrossRef]

49. Shen X, Yang S, Li G, Liu S, Chu F. The contribution mechanism of furfuryl alcohol treatment on the dimensional stability of plantation wood. Ind Crops Prod. 2022;186(11):115143. doi:10.1016/j.indcrop.2022.115143. [Google Scholar] [CrossRef]

50. Lebow ST, Lebow PK, Hirth KC. Laboratory immersion method for accelerated prediction of preservative leaching from treated wood exposed to precipitation. Wood Fiber Sci. 2019;51(1):1–14. doi:10.22382/wfs-2019-008. [Google Scholar] [CrossRef]

51. Pilgard A, Vetter DL, Acker JV, Westin M. Toxic hazard of leachates from furfurylated wood: comparison between two different aquatic organism. Environ Toxicol Chem. 2010;29(5):1067–71. doi:10.1002/etc.132. [Google Scholar] [PubMed] [CrossRef]

52. Lagel MC, Pizzi A, Basso MC, Abdalla S. Development and characterization of abrasive grinding wheels with a tannin-furfuryl alcohol resin matrix. Ind Crops Prod. 2014;65:333–48. [Google Scholar]

53. Lukmandaru G, Fatimah S, Fernandes A. Sifat kimia dan warna kayu keruing, mersawa, dan kapur. Jurnal Penelitian Ekosistem Dipterokarpa. 2015;1(2):69–80 (In Indonesian). doi:10.20886/jped.2015.1.2.69-80. [Google Scholar] [CrossRef]

54. Iroegbu AOC, Ray SS. On the chemistry of furfuryl alcohol polymerization: a review. Wiley: J Polym Sci. 2024;62(6):1044–60. doi:10.1002/pol.20230708. [Google Scholar] [CrossRef]

55. Guigo N, Mija A, Vincent L, Sbirrazzuoli N. Eco-friendly composite resins based on renewable biomass resources: polyfurfuryl alcohol/lignin thermosets. Eur Polym J. 2010;46(5):1016–23. doi:10.1016/j.eurpolymj.2010.02.010. [Google Scholar] [CrossRef]

56. Winandy J, Rowell R. Chemistry of wood strength. In: Handbook of wood chemistry and wood composites. Boca Raton, FL, USA: CRC Press; 2005. [Google Scholar]

57. Dong Y, Qin Y, Wang K, Yan Y, Zhang S, Li J. Assesment of the performance of furfurylated wood and acetylated wood: comparison among four fast growing wood species. BioResources. 2016;11(2):3679–90. doi:10.15376/biores.11.2.3679-3690. [Google Scholar] [CrossRef]

58. Li W, Wang H, Ren D, Yu YS, Yu Y. Wood modification with furfuryl alcohol catalyzed by a new composites acidic catalyst. Wood Sci Techol. 2015;49:845–56. [Google Scholar]

59. Mantanis G. Chemical modification of wood by acetylation or furfurylation: a review of the present scaled-up technologies. BioResources. 2017;12:4478–89. doi:10.15376/biores.12.2.4478-4489. [Google Scholar] [CrossRef]

60. Ihsan M. Sifat fisis dan mekanis kayu jabon (anthocephalus cadamba) hasil furfurilasi (Thesis). Institut Pertanian Bogor: Bogor, Indonesia; 2020 (In Indonesian). [Google Scholar]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools