Open Access

Open Access

ARTICLE

Fabrication and Mechanical, Dielectric and Optical Properties of Cellulose Paper Embedded with SrAl2O4:Eu,Dy Phosphor

1 Taras Shevchenko National University of Kyiv, Kyiv, 01601, Ukraine

2 National University of Life and Environmental Sciences of Ukraine, Kyiv, 03041, Ukraine

3 National Technical University of Ukraine “Igor Sikorsky Kyiv Polytechnic Institute”, Kyiv, 03056, Ukraine

4 Institute of Physics Polish Academy of Sciences, Warsaw, 02-668, Poland

* Corresponding Author: Vitalii Chornii. Email:

Journal of Renewable Materials 2025, 13(4), 653-668. https://doi.org/10.32604/jrm.2025.058211

Received 07 September 2024; Accepted 31 December 2024; Issue published 21 April 2025

Abstract

The work deals with cellulose paper filled with nanocellulose and SrAl2O4:Eu,Dy oxide phosphor. It was found that both nanocellulose and oxide improve the tensile strength of the composites obtained. The samples with the oxide demonstrate a long-lasting photoluminescence (PL) under sunlight and ultra-violet (UV) illumination. Room-temperature the PL spectra reveal a wide multicomponent band spreading over all the visible spectral regions. The short-wavelength part of the band is ascribed to the cellulose-related luminescence, while the long-wavelength PL component with maxima near 540 nm corresponds to the luminescence of the SrAl2O4:Eu,Dy phosphor. The dependency of the PL intensity on oxide concentration suggests the reabsorption of cellulose emission by the oxide and vice versa. The study of the dielectric properties of composite papers shows the presence of dielectric relaxations at low temperatures (T ~−50°C). Similar cellulose materials to those studied can be considered as alternatives for artificial petroleum-based polymers. Low cost, eco-friendliness, biocompatibility, and the simplicity of recycling are among the main advantages of these materials. They are produced from the cellulose which is one of the most abundant renewable materials in nature. The data on the mechanical, dielectric, and optical properties indicate that the papers studied can be used in flexible lighting devices, WLEDs, coating, markers, labels, etc.Graphic Abstract

Keywords

The wide application of artificial petroleum-based polymers (plastics) in modern technology results in substantial waste generation. According to the recent data of UNEP-UN Environment Programme [1], the current rate of plastic waste production in the world is nearly 400 million tons per year with a total amount of nearly 7 billion tons accumulated so far. This waste poses significant threats to both the environment and living beings. Research shows that microplastic particles are increasingly found in the human body (e.g., lungs, liver, brain) while the effect of this pollutant is not yet fully understood [2]. Unfortunately, most artificial polymers are discarded and only 10% of total plastic waste is recycled or reused nowadays. Thus, substitution of plastics with suitable eco-friendly materials is an urgent problem for modern science and technology. The cellulose and its derivatives can be used for the abovementioned purpose. Cellulose-based materials are biodegradable, so they can easily be composted [3]. Cellulose sources are abundant; numerous well-developed techniques of its production in various forms (global production of ≈1.5 × 1012 tons per year [4]) make this material cheap and competitive in comparison to artificial polymers.

“Paper electronics” is a technology in which cellulose derivatives are used as an alternative to plastics in electronics [5–7]. Cellulose and cellulose-based composites are used as substrates when cellulose hydrogels and nanocellulose with various additives serve as inks for printing of electrical schemes by conventional and 3D printing technologies [7–9]. The current and suggested applications of paper electronics devices include sensors (pressure, temperature, humidity, biosensors) [10–13], light emitting devices [14,15], solar cells [16], batteries [17], nanogenerators [18], etc. Although the chemical and physical properties of cellulose materials satisfy some basic requirements, the improvement of flexibility/stiffness, dielectric/conductivity, capacitance, light absorbance/emission is of high importance for enhancing the performance of the abovementioned devices. Such improvements can be done by incorporation of various additives (fillers) into the cellulose matrix.

Nanocellulose (NC) occupies a special place among the fillers, as it both improves the mechanical properties of cellulose materials and is eco-friendly. In particular, adding 2% of nanofibrillated cellulose to wood fibers improves tensile strength of the latter from 97.5 to 141 MPa [19]. This effect was ascribed to an increase in inter-fiber stress transfer when cellulose nanofibers either cover cellulose fiber or form additional porous membranes and foams in the pores of the larger scale cellulose networks. Remarkably, only a few wt. % of NC (nanofibers or nanocrystals) significantly improve mechanical and dielectric properties of cellulose paper [19,20].

Cellulose-based films offer quite high transparency in the visible spectral range (transmittance up to 90.7% was reported for cellulose nanopaper [21] and nearly 90% for regenerated cellulose film [22]). The cellulose and its derivatives luminesce under ultraviolet (UV) and visible light illumination [23–25]. However, the intensity of the luminescence of pure microcrystalline cellulose and nanocellulose is insufficient for practical application in lighting devices. In order to improve the luminescence properties a cellulose matrix can be incorporated with luminescent particles, such as carbon or semiconductor quantum dots [22,26], coordination complexes [27], or inorganic phosphors [28–30]. The rare-earth ions doped oxide phosphors attract the most attention as they offer a high luminescence intensity, long operational stability as well as low toxicity in comparison with semiconductor quantum dots or coordination complexes.

In this work, we report the effect of NC and SrAl2O4:Eu,Dy oxide with long-lasting luminescence on the mechanical, dielectric and optical properties of a cellulose paper. To the best of our knowledge a number of studies have explored on cellulose-based materials with SrAl2O4:Eu,Dy phosphor—cotton fibers [30], cellulose acetate nanofibrous films [31], regenerated cellulose fibers [32], and nanofibrillated cellulose films [33,34]. These materials were proposed for use in anti-counterfeiting purposes, luminous flexible equipment, interior decoration, night lighting, and portable logos or labels. In contrast to the abovementioned studies, in the present paper we report the simultaneous effect of cellulose and the oxide phosphor on mechanical and luminescence properties of the composite paper has been reported in this work. Additionally, this work serves as the first detailed study of the dielectric properties of the cellulose/nanocellulose/SrAl2O4:Eu,Dy composite paper. In our opinion, the data discussed in this work are necessary when using these composites in flexible paper electronics as substrate or active light emitting elements.

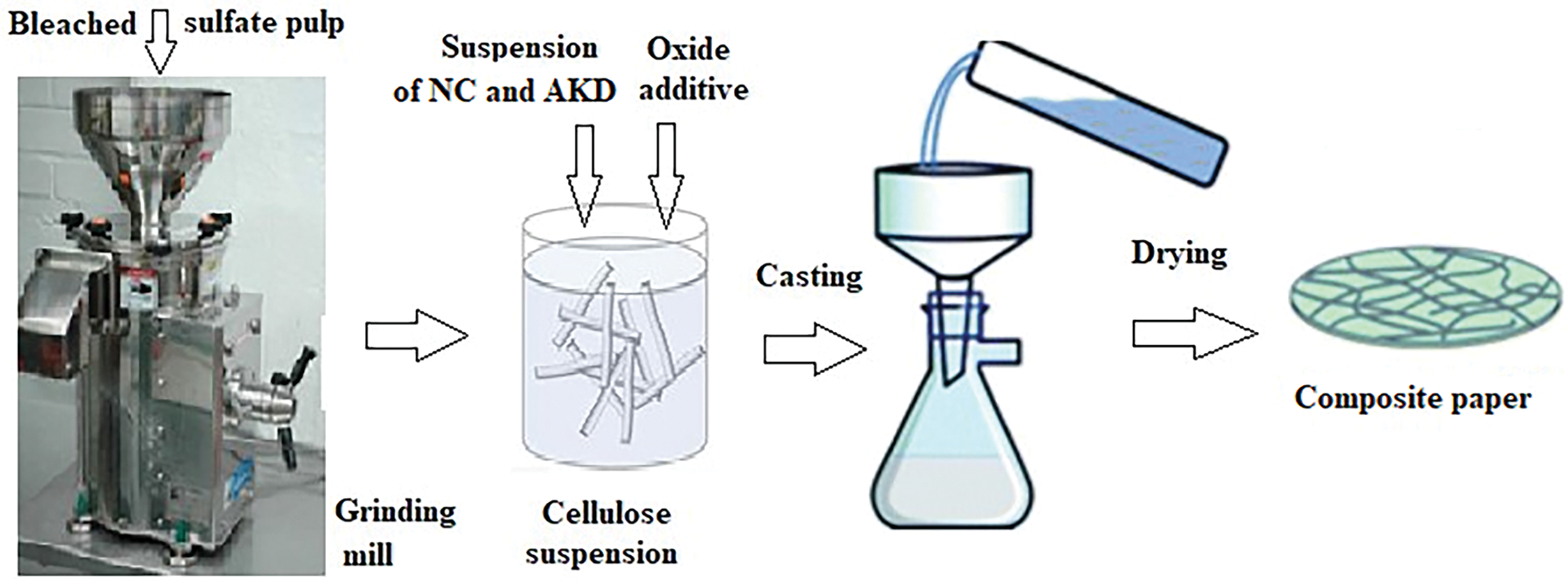

A bleached sulfate pulp from coniferous wood has been used as a fibrillar matrix for preparation of paper samples embedded with SrAl2O4:Eu,Dy luminescent oxide. This type of cellulose was chosen as one that provides the desirable parameters of tensile strength of composite paper and also allows studying their mechanical, dielectric and optical properties.

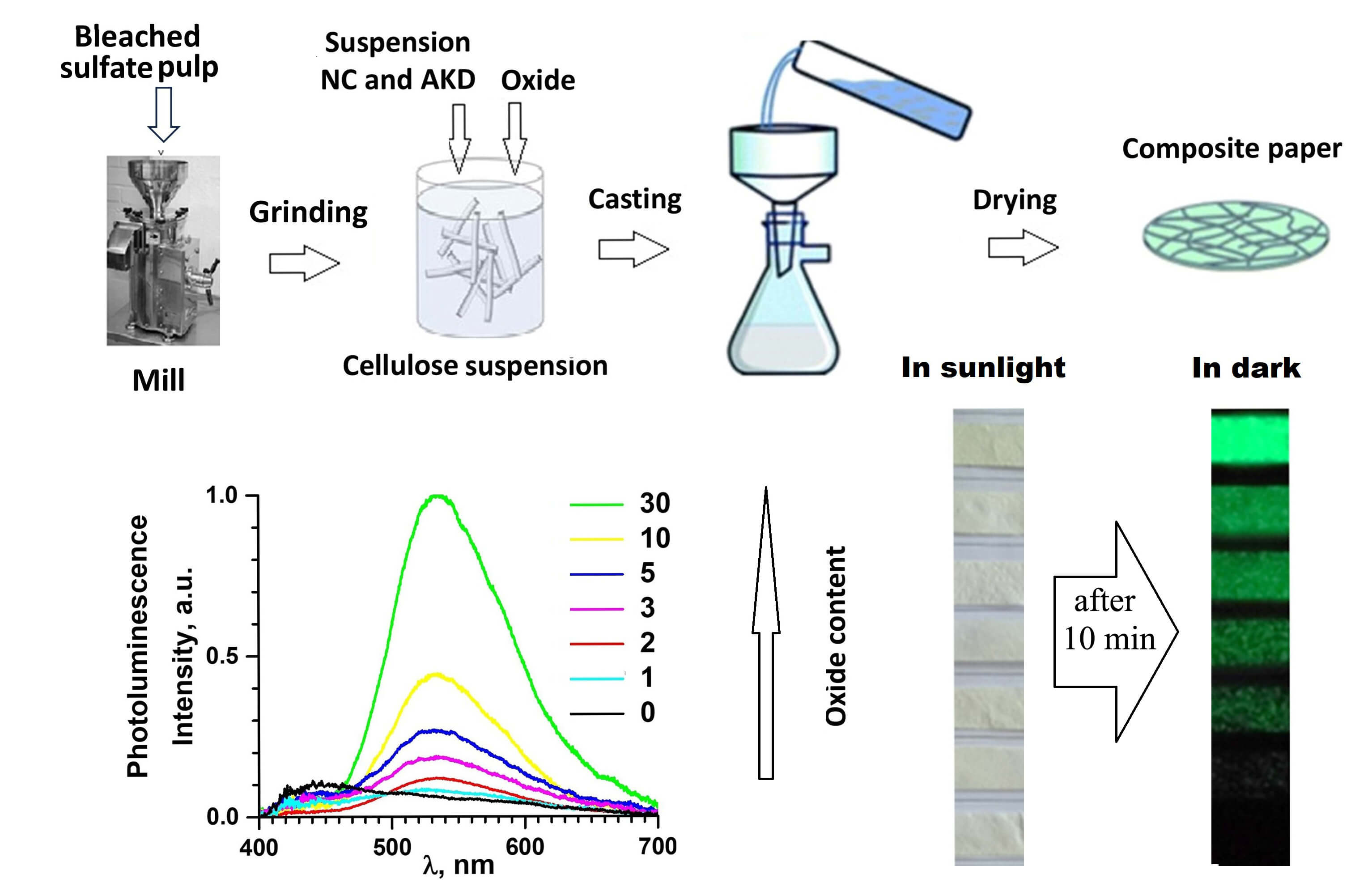

The process of sample preparation consists of the next steps. In the first stage, industrially produced sheets of wood pulp (as a source for the fibrillar matrix) were cut into pieces measuring ~50 mm × 50 mm. Then, these pieces were soaked in distilled water until they swelled with further grinding in a laboratory grinding mill (Fig. 1). The resulting suspension was characterized by the Schopper-Riegler test resulting in 55 ± 3 °SR degrees. To improve the mechanical properties of the composites, a suspension of NC from non-wood plant material was added to the cellulose mass at the consumption of 0.5 wt. % of the cellulose pulp. Nanocellulose acts as a strengthening component that binds the the fibers of the cellulose matrix. This NC was extracted from cellulose by ecologically friendly organosolv method with the application of techniques described elsewhere [35]. The paper gluing process was increased by adding a solution of alkyl ketene dimer with a consumption of 0.3 wt. % to the mass of the original wood pulp. The rationale behind the oxide filler concentration range accounted for the results of the work [33] where similar materials were studied. It was shown in [33] that 40 wt. % and more of the SrAl2O4:Eu,Dy filler decrease the mechanical properties of the paper. Consequently, concentration range 0–23 wt. % of the oxide powder has been taken for the research being described. The required mass of the oxide filler was weighted using an analytical balance (precision ± 0.001 g) and added to the suspensions noted above to prepare the luminescent composite paper.

Figure 1: Scheme of preparation of cellulose-based paper samples embedded with SrAl2O4:Eu,Dy luminescent oxide

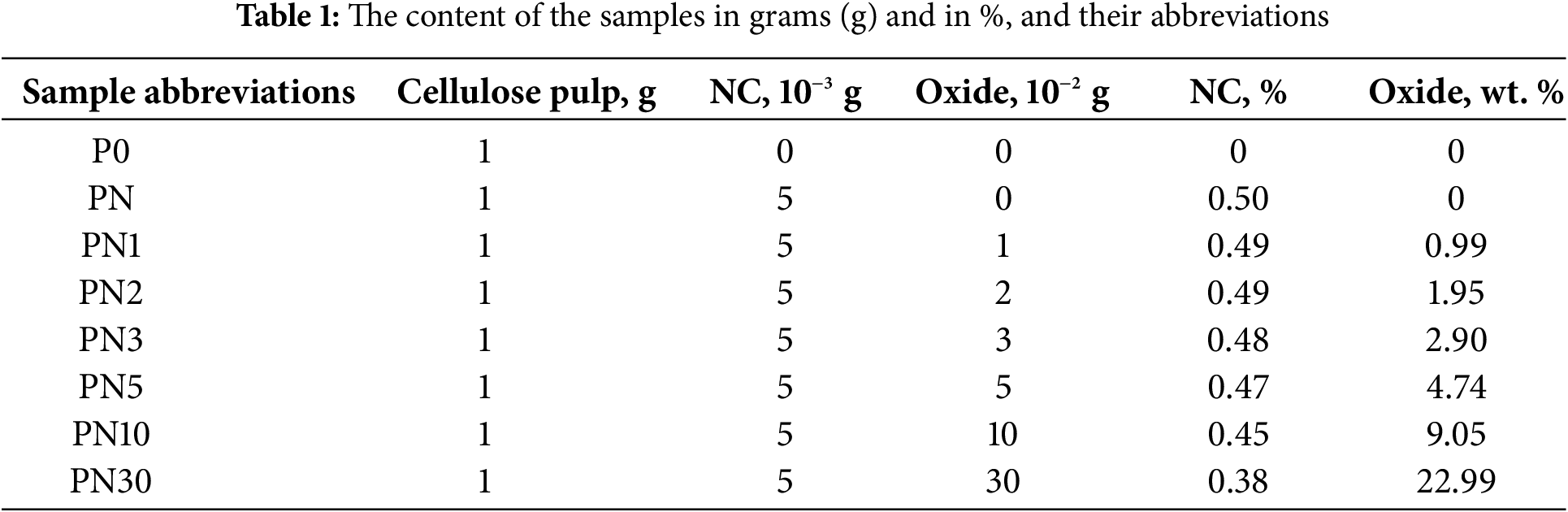

The obtained suspensions have been thoroughly stirred using magnetic stirring. On the next stage, the paper samples have been obtained by casting the suspension prepared using Büchner funnel and Bunsen flask in the form of disks 120 mm in diameter. The drying process was performed in a drying chamber under T = 97°C and pressure p = 93.1 kPa. The measured density of fibrillar suspension was 0.5 g/l and final density of dried paper disks was 100 ± 5 g/m2. The compositions and abbreviation of all samples produced are noted in Table 1 below.

2.2 Characterization Techniques

Optical images of the samples have been obtained using XS-3330 MICROmed microscope equipped with a digital camera.

The Tescan Vega 3 electron microscope was used for study of the samples morphology. Accelerating voltage was from 1 to 25 kV and maximal resolution riches 3 nm.

The physico-mechanical parameters, namely tensile strength of the composite papers, have been studied for the case of 15 mm wide strips that were cut from the abovementioned paper discs. These studies have been performed on RBM-30-2M vertical bursting machine. The values of the tensile strength (TS in N/m2) were calculated by the formula TS = Р/(t·a), where t—sample thickness, in m; а—sample width, in m.

The dielectric properties of the composite paper, namely real and imaginary parts of complex dielectric permittivity, have been studied in −190°C–90°C temperature range and in the 5 to 50 kHz frequency range. An automated installation based on a P5083 AC bridge and a thermostated four-electrode cell has been used for the measurements of capacity and dielectric loss tangent [36,37].

The photoluminescence properties have been studied using a modernized DFS-12 spectrometer (equipped with FEU-100 photomultiplier tube) and a Horiba/Jobin-Yvon Fluorolog-3 spectrofluorometer. The ultraviolet (UV) diodes (λrad/ex = 265, 365 and 395 nm) as well as powerful xenon arc lamps were used as sources of the PL excitation.

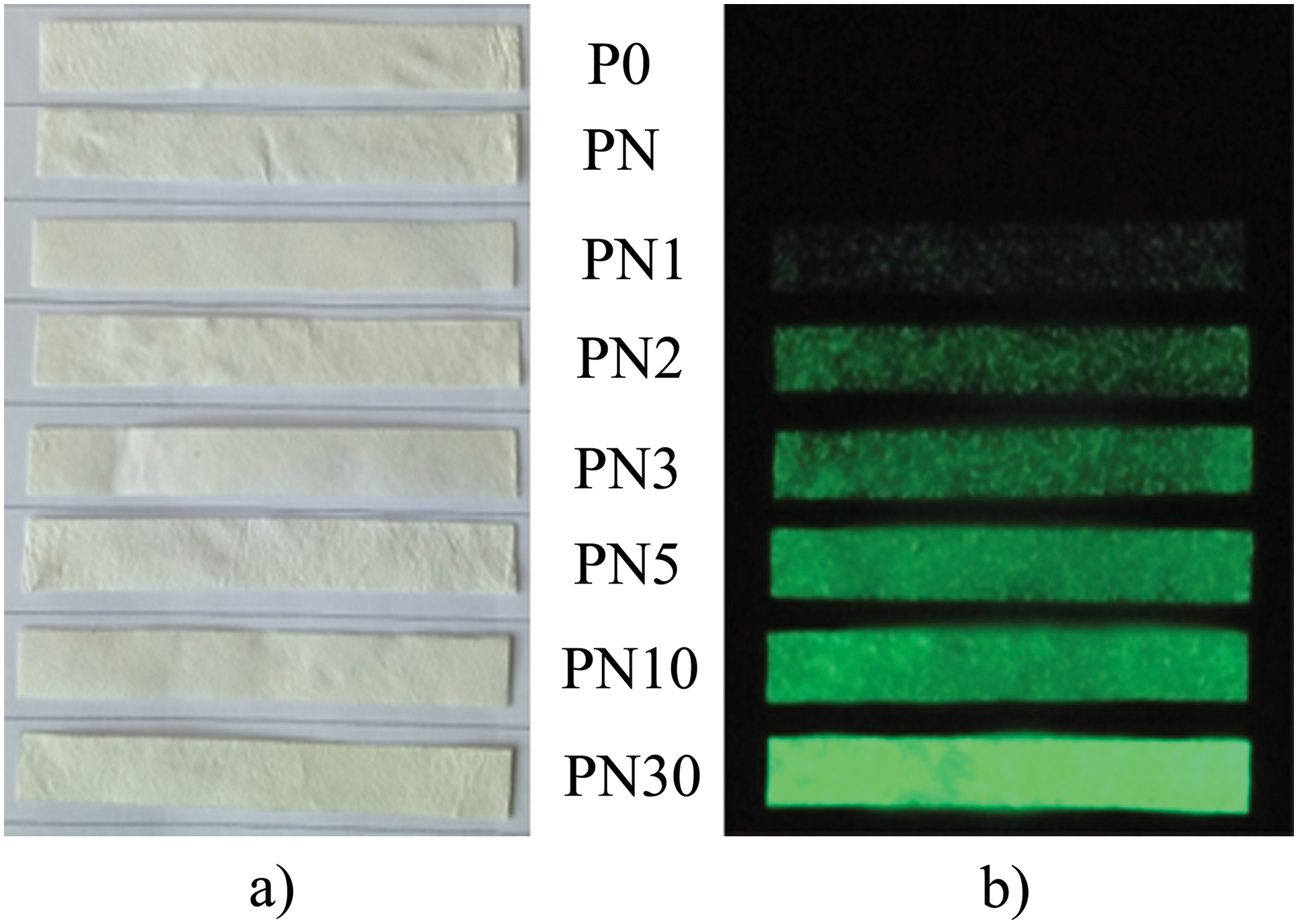

A general view of the composite paper strips under daylight illumination can be found in Fig. 2a. The surface of the samples appears in a yellowish hue that can be ascribed to absorption of the violet/blue light by cellulose and the oxide accompanied by some luminescence of these components. After illumination by daylight or UV light, composite paper samples exhibit an intensive, long-lasting luminescence) (Fig. 2b).

Figure 2: Photos of the strip samples taken under daylight illumination (a) and after 10 min of daylight exposure taken in a dark room (b)

3.1 Optical and Scanning Electron Microscopy

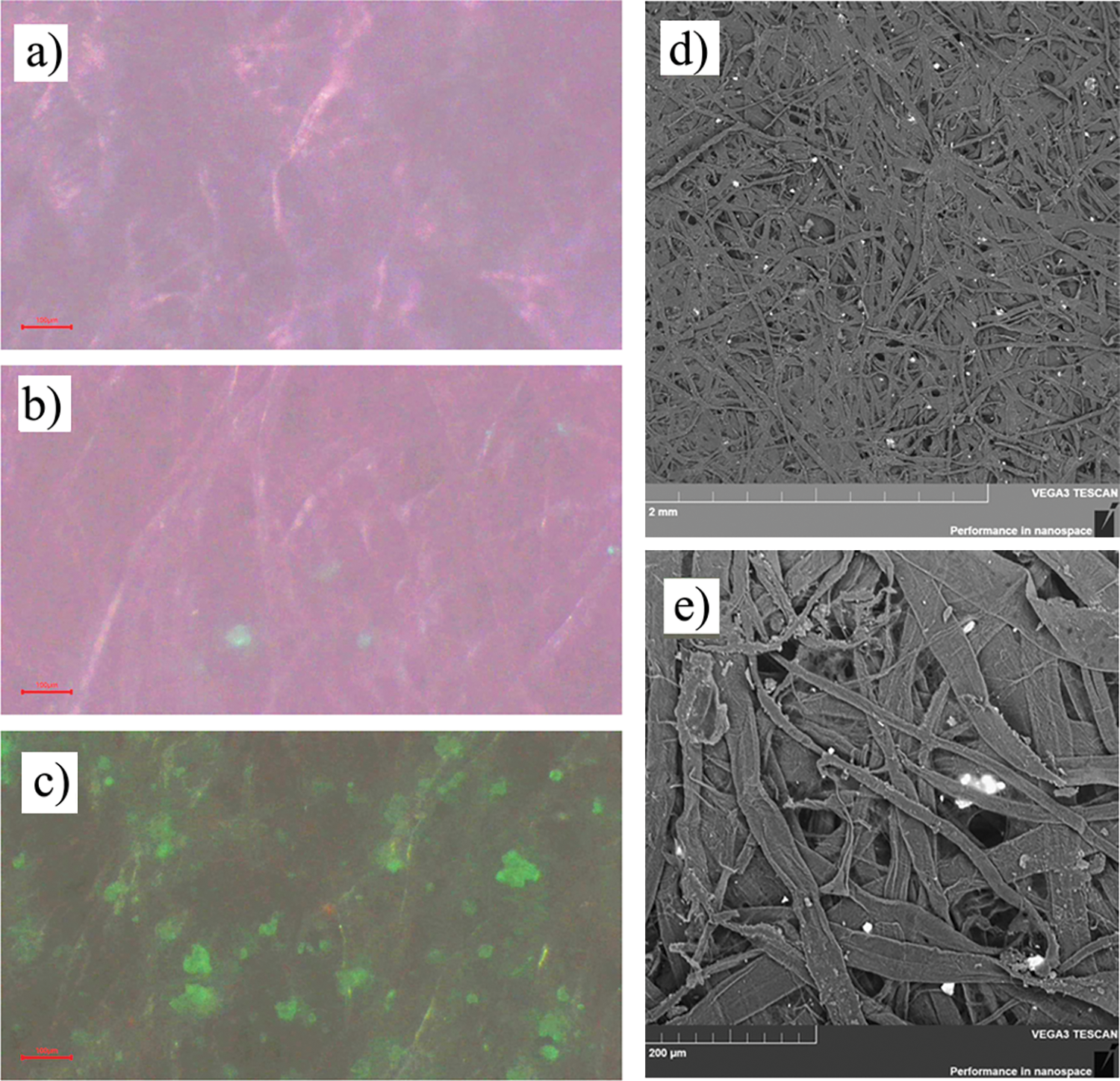

Fig. 3 shows that the samples studied consist of intertwined cellulose fibrils (thickness ~10 μ) that form a porous network. The structure of the samples suggests that incorporated SrAl2O4:Eu,Dy oxide nano/microparticles are located both on the surfaces of fibrils and between them, in pores. The samples without oxide, PN0 and PN1, are characterized by weak blue luminescence after illumination with UV light at λex = 265 nm (Fig. 3b,c) due to the own luminescence of the cellulose host. The larger oxide particles and their agglomerates can be easily seen in the optical microscope images of the samples, PN1-PN30, owing to the bright green luminescence of these particles (Fig. 3c). It should be noted that the visible sizes of particles and agglomerates in Fig. 3c exceeds their real sizes due to the luminescent radiation scattering on the samples’ inhomogeneities. The particles of the oxide filler are observed in SEM images as bright light dots with a size of 0.1 to 10 μ including their clusters (Fig. 3d,e).

Figure 3: Optical, under UV light illumination (left; the scale bar is 100 μ), and SEM images (right) of P0 (a), PN3 (b), PN30 (c), and PN10 (d, e) samples

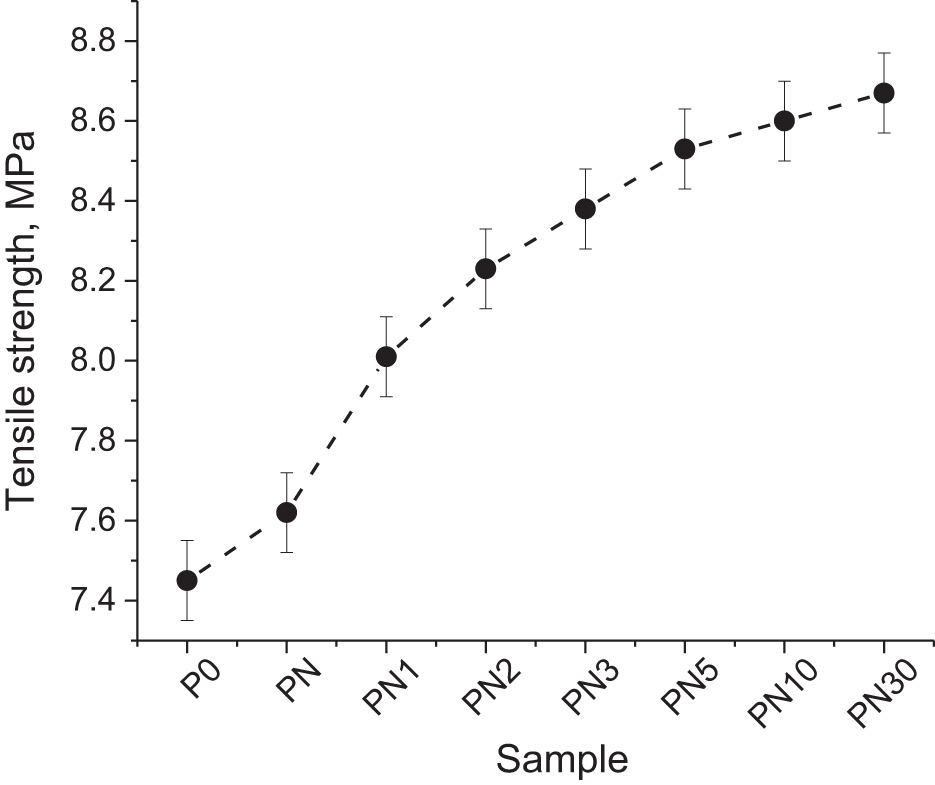

A dependence of tensile strength on sample compositions is shown in Fig. 4. It was found that 0.5 wt. % nanocellulose improves the tensile strength of cellulose paper on about 2%. The improvement of mechanical properties (namely tensile strength and index) of paper by nanocellulose fibers or nanocrystals has been widely described in the literature [38–40].

Figure 4: Dependence of tensile strength on composition of the samples

The simultaneous effect of nanocellulose and oxide fillers provides increase of the tensile strength by up to 16%. The improvement of tensile strength by oxide addition has been previously reported in [41,42]. In instance, the cellulose nanocrystals and ZnO significantly improved the mechanical properties of poly(vinyl alcohol)/chitosan blend films [41]. Mechanical properties of the modified cellulose acetate membrane had been successfully improved by ZrO2 layers [42]. At the same time particles SiO2@SrAl2O4:Eu,Dy degraded mechanical properties of polymer films based on TEMPO-oxidized nanofibrillated cellulose [33]. In case of regenerated cellulose, incorporation up to 8 wt. % of SrAl2O4:Eu,Dy particles into fibers has almost no effect on the rigidity of the material, while further increasing of the oxide content to 12 wt. % leads to significant decrease (almost twice) of tensile strength [32]. It was supposed that inorganic particles disturb oriented fiber structure, although they increase the number of entanglement points between cellulose fibers [32]. These processes have an opposite effect on the mechanical properties of polymer composites.

A tensile strength dependence on the amount of the filler (Fig. 4) is nonlinear and reveals a tendency to saturation despite the increasing amount of solid oxide particles. Consequently, the results confirmed an assumption that incorporated particles “reduced the number and strength of the hydrogen bonds” which provides the binding cellulose fibrils [33]. At the same time, it should be pointed out that in our research tensile strength is increased when the content of the oxide reaches 23 wt. %, while as it is reported in the work [32] an incorporation of more than 8 mas. % of SrAl2O4:Eu,Dy is accompanied by the tensile strength decrease. Thus, our results can be explained by an impact of the nanocellulose introduced to the composition of the studied papers.

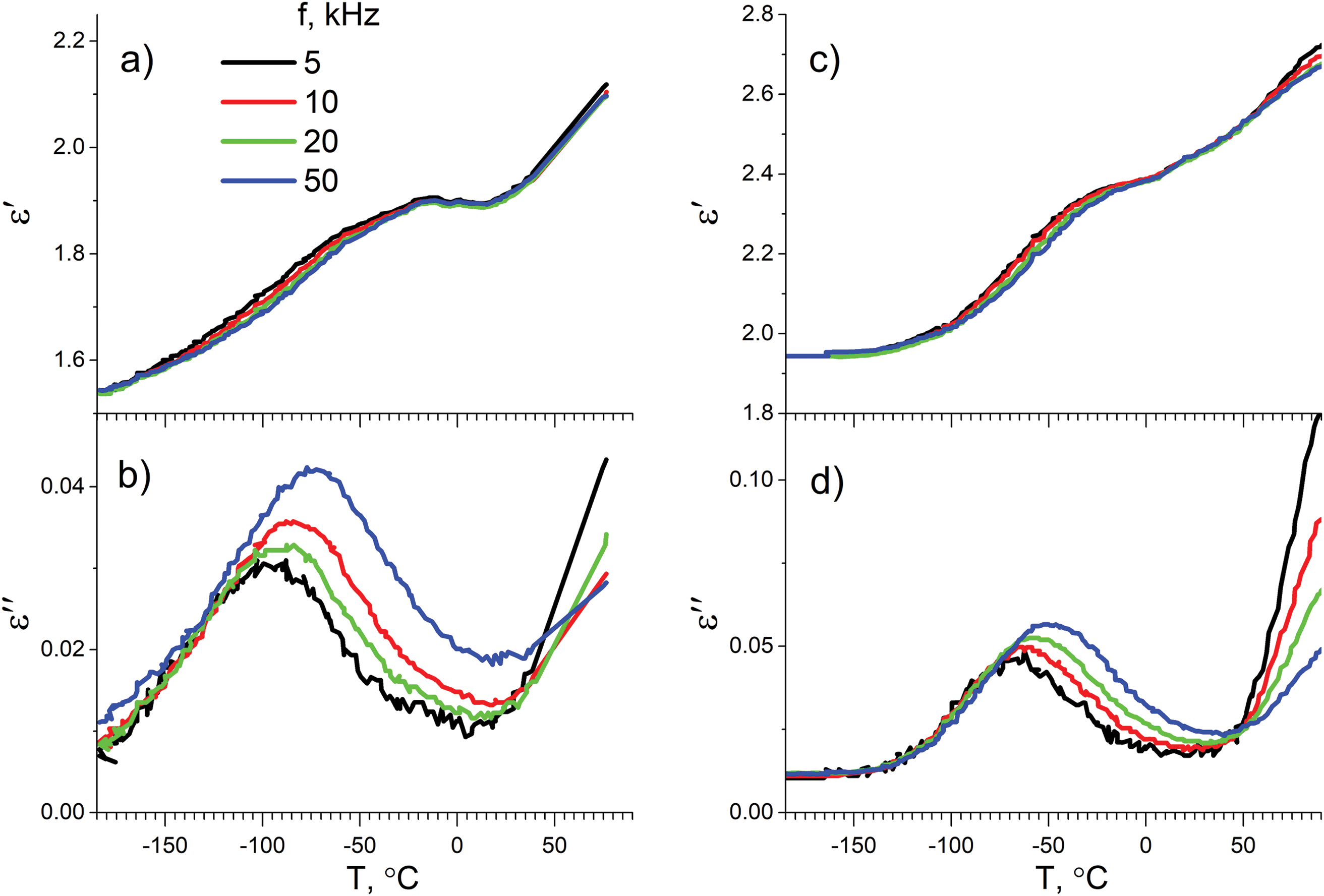

The temperature dependences of the real ε´(T) and imaginary ε´´(T) parts of complex dielectric permittivity at four frequencies for PN and PN30 samples are shown in Fig. 5. The curves of ε´(T) for the samples contain band at low temperature (maxima near −20°C). This band moves toward higher temperatures when frequency increases. This shift indicates the relaxation nature of this band.

Figure 5: Temperature dependencies of real (a, c) and imaginary (b, d) parts of complex dielectric permittivity for PN (a, b) and PN30 (c, d) samples

Curves of imaginary part ε´´(T) of complex dielectric permittivity for the samples also reveal a band in −190°C–0°C temperature range. As in case of ε´(T) dependence, the shift of band maxima toward higher temperature with increasing of frequency additionally indicates the relaxation nature of this band.

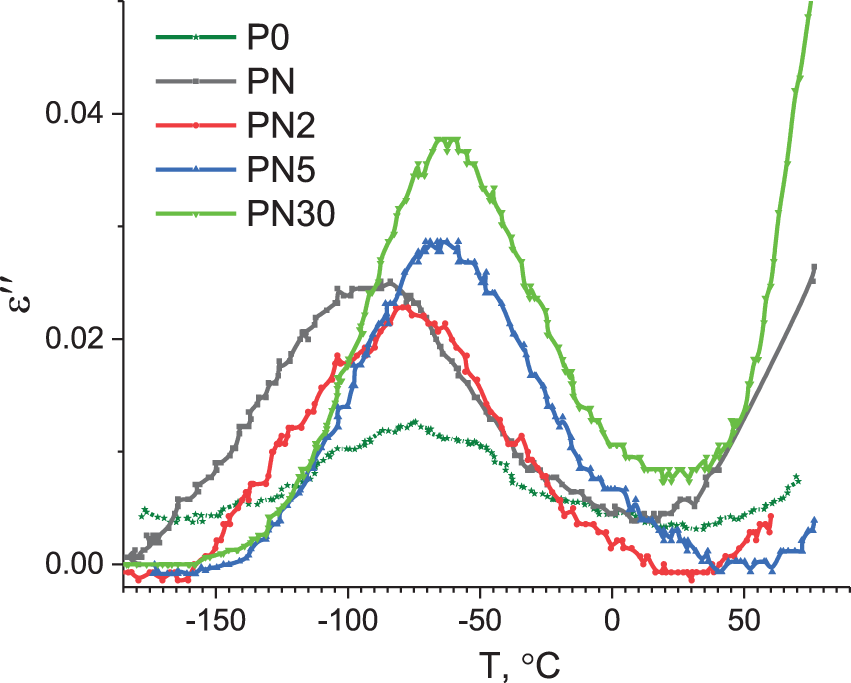

In order to analyze the effect of oxide content on the abovementioned relaxation process the dependencies of ε´´(T) for the studied samples are shown at the same frequency (Fig. 6). It worth noting, that SrAl2O4:Eu,Dy content increase leads to the relaxation region shifting to higher temperatures and the intensity of relaxations increasing.

Figure 6: Temperature dependencies of imaginary part of complex dielectric permittivity obtained for frequency f = 10 kHz

The parameters of the abovementioned relaxation processes can be estimated from the model system of the identical relaxers each of those have two energetically non-equivalent positions separated by potential barrier [43–45]. Within a framework of this model the dependencies of real and imaginary parts of complex dielectric permittivity can be described by Eqs. (1) and (2), as it was proposed earlier [43]:

where ε∞—dielectric permittivity at high frequencies (related with elastic polarization mechanisms), Δε´(T)—dependence of dielectric permittivity increment on temperature,

Relaxation time can be described by Eq. (3):

where ω0—frequency of the relaxer vibrations at equilibrium position, U—activation energy, V–difference in energy for relaxer in 1 and 2 positions, k—Boltzmann constant.

The temperature dependence of dielectric permittivity increment can be described by Eq. (4):

where N is relaxers concentration, μ—average difference of dipole moment of relaxers in positions 1 and 2, ε0—electric constant.

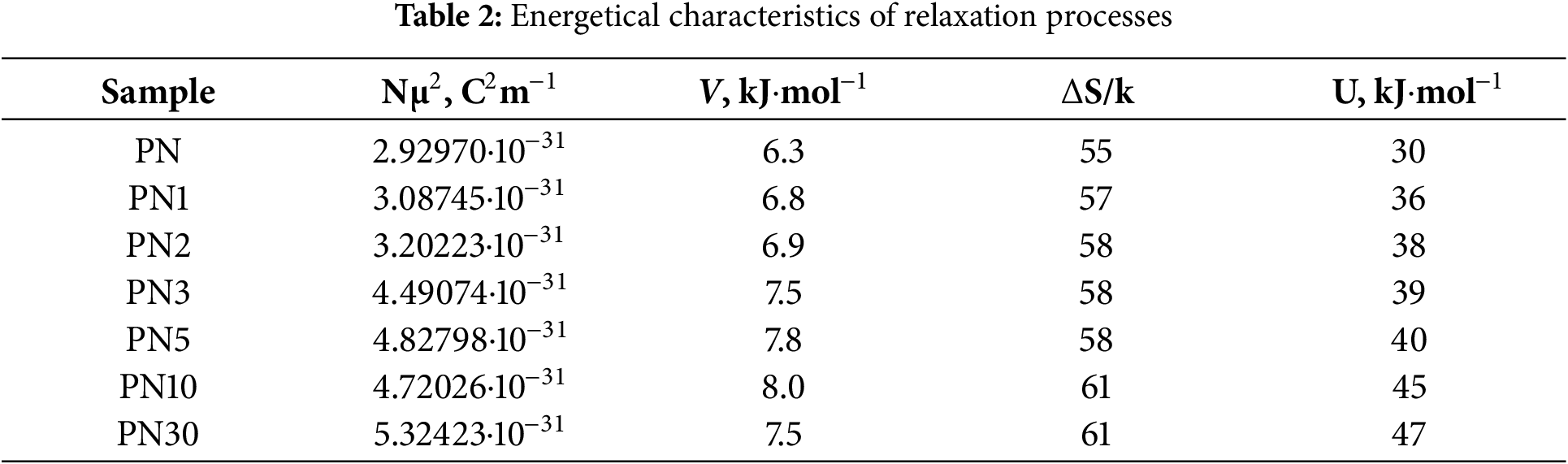

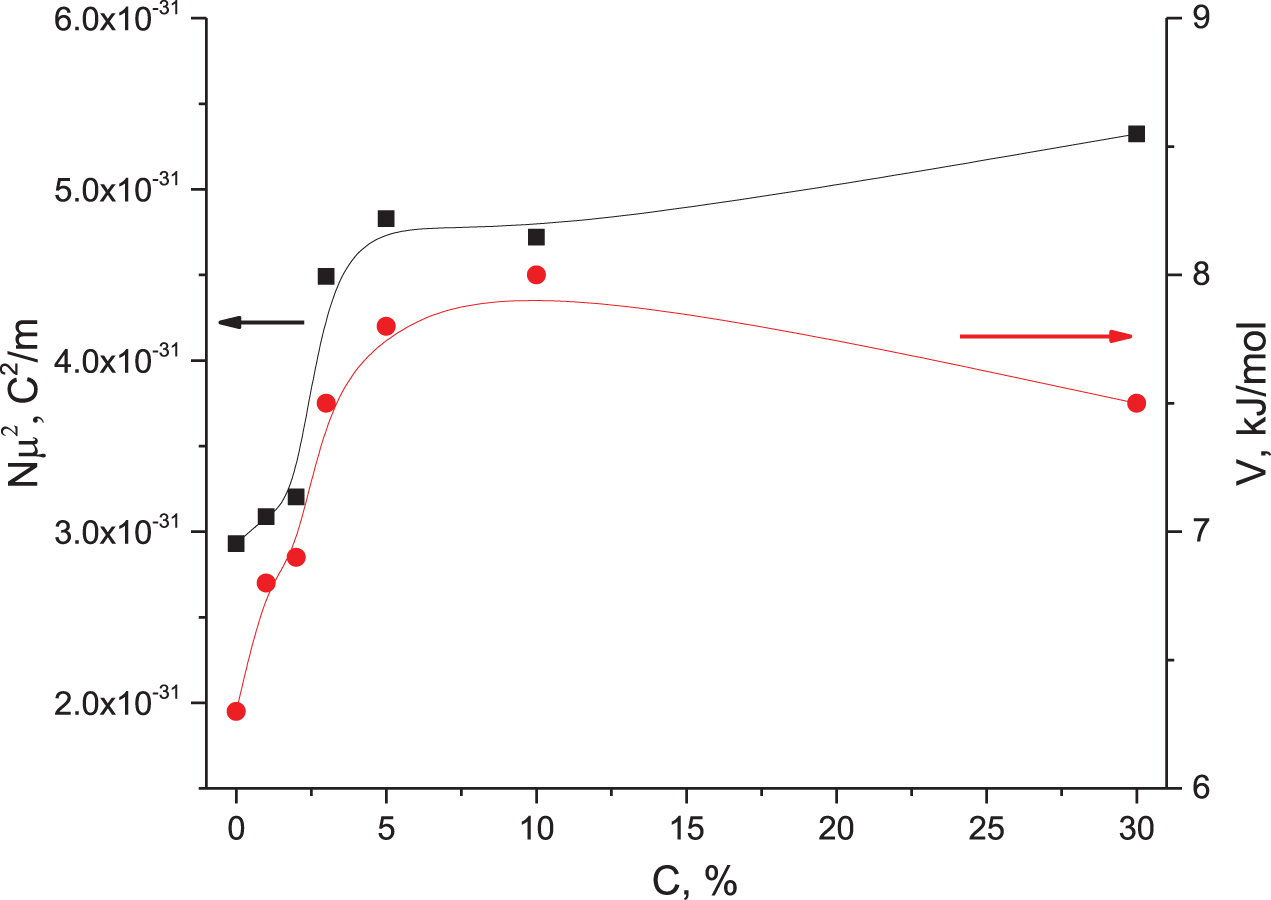

Approximation of temperature dependencies of ε´(T) by Eq. (4) at the high temperature part of relaxation band (−15°C–0°C region at Fig. 5) where ωτ << 1 allowed us to estimate the Nμ2 and V parameters (obtained values are collected in Table 2). It can be seen from the Table 2, that energy difference V for relaxer in two states as well as concentration of relaxers increase with oxide content increasing. Both the Nμ2 and V parameters reach their maximum values at ~5 wt. % of oxide in composites, as it follows from Nμ2 and V dependencies on concentration (Fig. 7).

Figure 7: The dependencies of relaxer concentration (black squares) and energy difference V (red circles) on SrAl2O4:Eu,Dy concentration

In case of U >> V and when the entropy of activation is taken into account for relaxation time, the value of the last one can be calculated by Eq. (5):

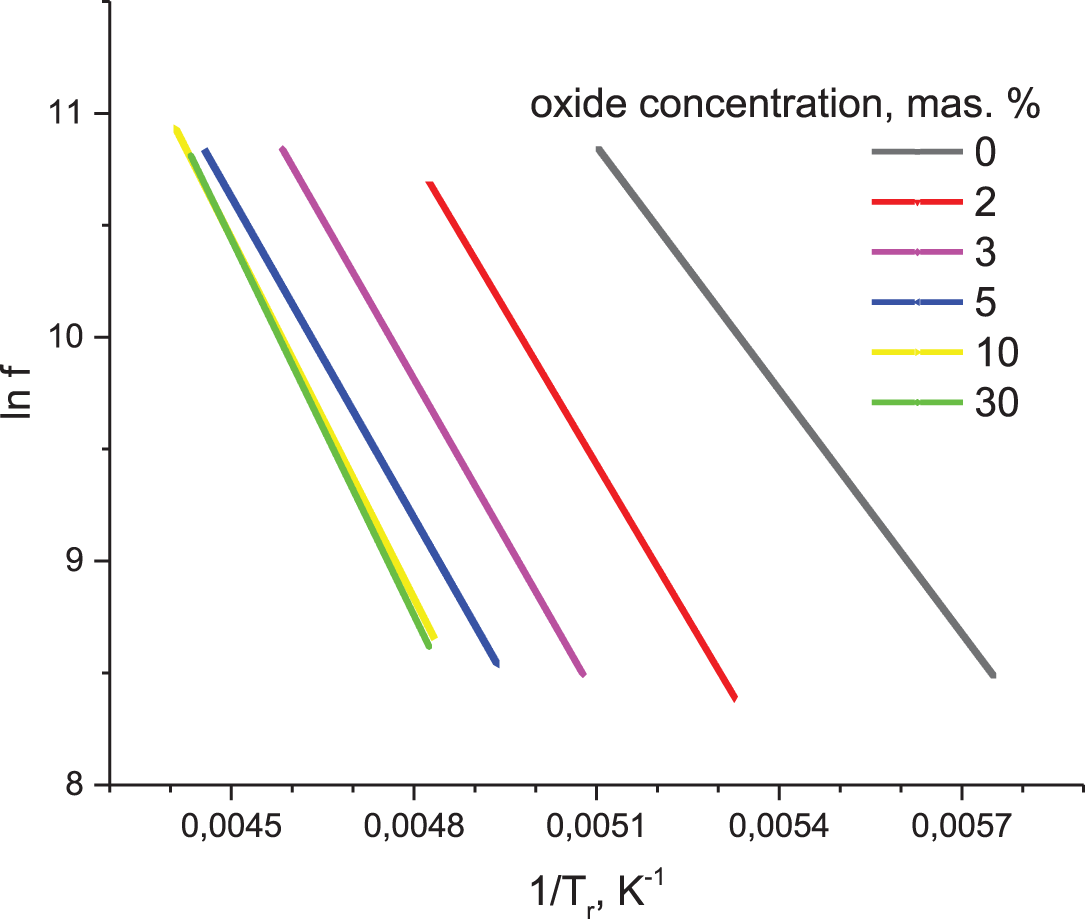

where τ0 = 10−12 c, ΔS—entropy of activation [40]. The condition of maximum for relaxation process at ε′′(T, f) dependence can be written as ωτ = 1. Consequently, some relaxer parameters can be obtained by approximation of ln f(1/Tr) dependencies with ln f = −ln 2πτ0 + ΔS/k + U/kT formula (see. Fig. 8). The estimated entropy of activation ΔS/k and activation energy U are collected in Table 2. It is seen, that both abovementioned parameters rise with SrAl2O4:Eu,Dy concentration increasing. The increase of the activation energy indicates that SrAl2O4:Eu,Dy particles prevent some transformations of cellulose-building units.

Figure 8: The dependences of logarithm of frequency on inverse temperature (1/Tr) of relaxation band maxima at ε´´(T) curves for composite samples with different SrAl2O4:Eu,Dy concentration

It is known that cellulose consists of anhydroglucose units carrying two hydroxyl groups (−OH) and one methylol group (−CH2–OH). According to Einfeldt et al. [46], there are three types of dipolar and movable sites—the pyranose ring (movable by orientational motions around the glucosidic bonds) and two side groups with rotation mobility around C-O linkage. The rotations of the methylol side-group are responsible for low-temperature relaxations [45–47]. Thus, we suppose that SrAl2O4:Eu,Dy particles prevent the reorientations of the (−CH2–OH) methylol side-groups in the cellulose molecules.

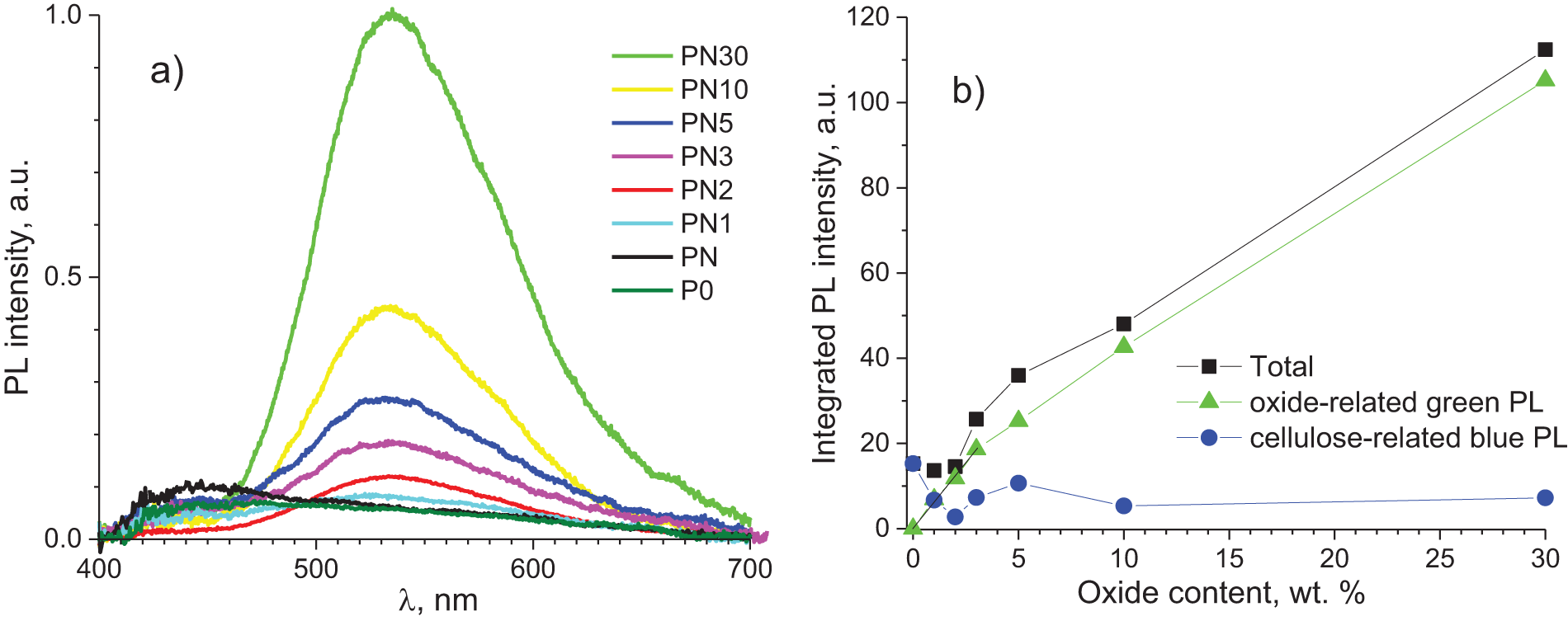

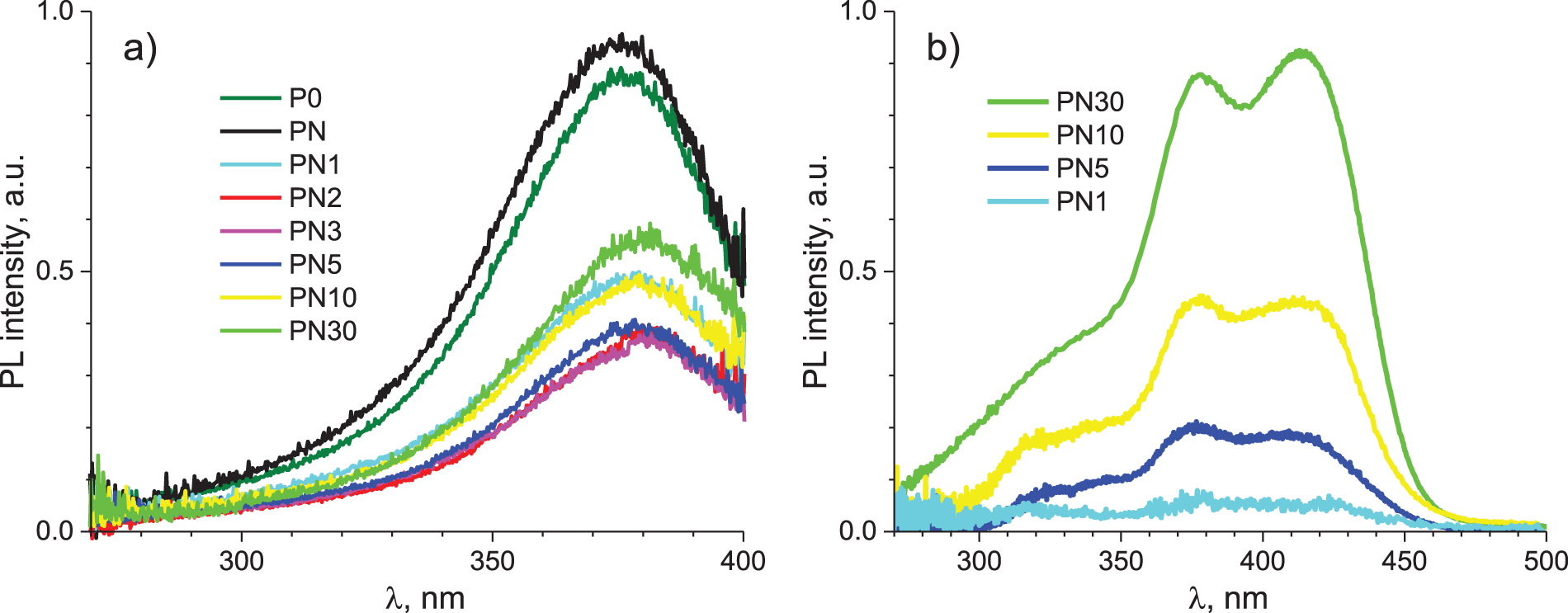

As was shown earlier [33], the composite paper with SrAl2O4:Eu,Dy filler reveals intensive green luminescence even under daylight illumination. The photoluminescence (PL) spectra of the studied samples are shown in Fig. 9a. The PL spectrum of initial paper P0 consists of an asymmetric complex band with an overall maximum in the blue spectral region near 450 nm. This band has been numerously reported for various forms of cellulose but the nature of this luminescence is still under discussion [23–25,48,49]. It is known that nanocellulose (nanocrystal and nanofibrils) reveals blue luminescence [50], thus this emission should be imposed with emission from cellulose fibers. In fact, a nanocellulose filler increases the intensity of short-wavelength part of emission of the composite paper but has almost no effect at the region of λ > 500 nm.

Figure 9: (a) The PL spectra of the samples measured under excitation at λex = 365 nm, T = 290 K; (b) the dependencies of integrated luminescence intensities on oxide concentrations

Significant changes in the luminescence of the papers studied have been observed for the samples embedded with oxide filler. The luminescence of these samples is long-lasting; thus, it can be registered for many hours after the photoexcitation has been turned off. Depending on cellulose source, the typical lifetime constants for cellulose-related luminescence range only from a few to several hundreds of milliseconds [24]. Thus, the green luminescence of the studied composite samples can be ascribed solely to SrAl2O4: Eu,Dy oxide emission. This PL is related to electron and hole trapping and releasing. Several possible trapping/releasing mechanisms have been discussed so far: 1) hole released by Eu2+ ion to the valence band (VB) → hole trapped by Dy3+ ion → hole released by Dy4+ ion → phosphorescence as a result of hole recombination with excited Eu1+ ion [51]; 2) electron released by Eu2+ ion to the conduction band (CB) → electron trapped by Dy3+ ion → thermal release of the electron from Dy2+ ion → luminescence as a result of hole recombination with excited Eu3+ ion [52]; 3) luminescence of SrAl2O4:Eu,Dy originates from the photo-oxidation of Eu2+ cations under UV irradiation, and electron traps are oxygen vacancies located nearby photo-generated Eu3+ ions [53]; 4) this is the model that included the models #2 and #3 [54], etc. However, additional experimental data requires for deeper understanding of the energy trapping/releasing mechanisms of the Sr(Ca)Al2O4:Eu,Dy luminescence [55–58].

A wide band of the green PL with a maximum near 540 nm dominates in the PL spectra regardless of the SrAl2O4:Eu,Dy concentration. It is observed that the blue emission from cellulose/nanocellulose is considerably suppressed at 2 wt. % of oxide. This effect is depicted in the dependencies of the integrated PL intensities on oxide concentration (Fig. 9b). As it follows from the data, the dependency of green PL on SrAl2O4:Eu,Dy content has two linear regions: 1) when X < 3 wt. % (this part can be approximated by line I (X) = 6X); 2) when 3 < X < 30 wt. %. This part can be approximated by the line I (X) = 9 + 3.2X. In our opinion, the radical change in the increase index results from a sharp increase in the rate of excitation energy transfer from the matrix to the Eu2+ luminescence centers in the oxide filler when the distance between oxide particles is shortening.

The PL excitation spectra have been measured at emission registration in the blue and green PL bands (Fig. 10). The blue luminescence is effectively excited in a wide band with maxima near 370 nm (Fig. 10a). As for the samples with oxide, the maximum of the excitation band is shifted toward longer wavelengths due to overlapping of cellulose- and oxide-related emission (see Fig. 9a). Excitation spectra of the green emission substantially differ from those for the blue PL. In particular, there are at least three PL excitation bands with maxima near 320, 370 and 420 nm. It was reported earlier that PL excitation spectrum of SrAl2O4: Eu,Dy phosphor consists of a wide single band in 270–450 nm region with maximum near 350 nm [59]. This band has been ascribed to the inter-configurational transitions from the ground 4f7 state to the excited 4f65d1 state in Eu2+ ions. Interestingly, the PL excitation band with maxima near 420 nm was observed earlier for TEMPO-oxidized nanofibrillated cellulose filled with SiO2@SrAl2O4: Eu,Dy particles [33]. In our opinion, the bands at 320 and 420 nm are more likely to be connected with cellulose-related light absorption centers. Detailed studies of the PL characteristics, especially of the PL decay and thermo-stimulated glow curves should be performed in the future to assign specific PL excitation bands to cellulose- or oxide luminescence centers.

Figure 10: The PL excitation spectra measured at λem = 450 (a) and 550 nm (b); T = 290 K

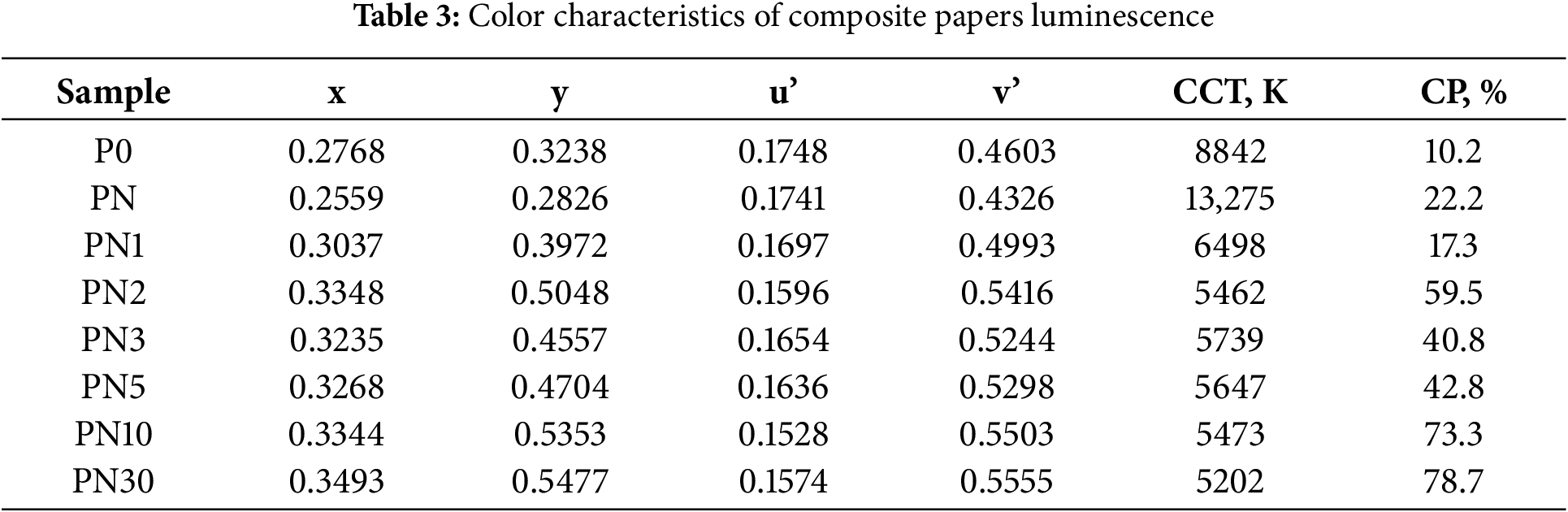

From the viewpoint of the light emitting devices application, it is important to know the color characteristics of the composite papers, which are chromaticity (x, y) and (u’, v’) coordinates according to CIE 1931 and CIE 1976 standards; correlated color temperature (CCT) and color purity (CP). The data have been estimated from the PL spectra measured at PL excitation at 365 nm (Fig. 9) and the data were collected in Table 3. The CCT values were calculated by the well-known empirical McCamy formula [60]. The CP values have been calculated by the method described in [61]. The obtained CCT values correspond to the “cold” radiation (T > 4500 K). Low color purity values are associated with the spread of the PL band over the entire visible light range. This result indicates that the studied materials could not be applicable where high color rendering is necessary (e.g., displays), but they can be used as components of low-power lighting devices. The observed non-monotonous behavior of CCT and CP regarding oxide content is more likely to be related with the reabsorption of cellulose emission by oxide and vice versa.

The composite paper samples consisting of a cellulose paper as a matrix, nanocellulose and an oxide SrAl2O4:Eu,Dy long-lasting phosphor as fillers have been produced and studied. The composites incorporated with the luminescent oxide consist of intertwined cellulose fibrils with oxide particles between them.

The combined effect of nanocellulose and oxide phosphor on mechanical, luminescent, and dielectric properties of the produced papers has been studied for the first time.

Temperature dependencies of dielectric permittivity indicate the presence of dielectric relaxations. The analysis of fitting parameters and their relation with the content of oxide particles suggests the presence of interaction between cellulose matrix and filler.

The prepared composite papers showed both blue and green luminescence bands under UV and visible light exposure. The former is attributed to the cellulose fibrils, while the latter is due to the radiation transition in Eu2+ ions. The green luminescence intensity significantly increases, while the intensity of the blue band decreases with increasing oxide filler content.

The effect of the fillers ensured an increase in the tensile strength of the paper by up to 16% and its luminescence intensity by a factor of 8.3.

The properties of these composite make well-suited for the use as a portable logo and label substrate, or as an active light-transforming material of flexible paper electronics.

Acknowledgement: Serhii G. Nedilko thanks the Polish Academy of Sciences for the possibility of the research stay and spectroscopy measurements at the Institute of Physics PAS, Warsaw, Poland during these difficult times for Ukraine. Syed Shabhi Haider, Yaroslav Zhydachevskyy, Andrzej Suchocki thank the Polish National Science Centre for supporting their participation in this work. The authors thank for P.O. Teselko who performed SEM experiments.

Funding Statement: The work of Vitalii Chornii, Serhii G. Nedilko, Maxim Lazarenko, Mariia Sosnovs’ka, Valerii Barbash, and Olga Yashchenko was financed by the National Research Foundation of Ukraine (Project No. 2022.01/0168).

Author Contributions: The authors confirm contribution to the paper as follows: conception and design: Serhii G. Nedilko; data collection: Oleksandr Alekseev, Valerii Barbash, Vitalii Chornii, Syed Shabhi Haider, Mariia Sosnovs’ka, Olga Yashchenko, Yaroslav Zhydachevskyy; analysis and interpretation of results: Valerii Barbash, Vitalii Chornii, Serhii G. Nedilko, Maxim Lazarenko, Andrzej Suchocki, Yaroslav Zhydachevskyy; draft manuscript preparation: Vitalii Chornii, Maxim Lazarenko, Serhii G. Nedilko. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data that support the findings of this study are available from the corresponding author upon reasonable request.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

Nomenclature

| CB | Conduction band |

| NC | Nanocellulose |

| PL | Photoluminescence |

| UV | Ultraviolet |

| VB | Valence band |

References

1. UN Environment Programme. Our planet is choking on plastic. [cited 2024 Sep 6]. Available from: https://www.unep.org/interactives/beat-plastic-pollution. [Google Scholar]

2. Vethaak AD, Legler J. Microplastics and human health. Science. 2021;371(6530):672–4. doi:10.1126/science.abe5041. [Google Scholar] [PubMed] [CrossRef]

3. Sánchez-Safont EL, González-Ausejo J, Gámez-Pérez J, Lagarón JM, Cabedo L. Poly (3-hydroxybutyrate-co-3-hydroxyvalerate)/purified cellulose fiber composites by melt blending: characterization and degradation in composting conditions. J Renew Mater. 2016;4(2):123–32. doi:10.7569/JRM.2015.634127. [Google Scholar] [CrossRef]

4. Reimer M, Zollfrank C. Cellulose for light manipulation: methods, applications, and prospects. Adv Energy Mater. 2021;11(43):2003866. doi:10.1002/aenm.202003866. [Google Scholar] [CrossRef]

5. Sabo R, Yermakov A, Law CT, Elhajjar R. Nanocellulose-enabled electronics, energy harvesting devices, smart materials and sensors: a review. J Renew Mater. 2016;4(5):297–312. doi:10.7569/JRM.2016.634114. [Google Scholar] [CrossRef]

6. Figueira J, Bonito RM, Carvalho JT, Vieira EMF, Gaspar C, Loureiro J, et al. Screen-printed, flexible, and eco-friendly thermoelectric touch sensors based on ethyl cellulose and graphite flakes inks. Flex Print Electron. 2023;8(2):025001. doi:10.1088/2058-8585/acc114. [Google Scholar] [CrossRef]

7. Jain K, Wang Z, Garma LD, Engel E, Ciftci GC, Fager C, et al. 3D printable composites of modified cellulose fibers and conductive polymers and their use in wearable electronics. Appl Mater Today. 2023;30(1):101703. doi:10.1016/j.apmt.2022.101703. [Google Scholar] [CrossRef]

8. Cunha I, Ferreira SH, Martins J, Fortunato E, Gaspar D, Martins R, et al. Foldable and recyclable iontronic cellulose nanopaper for low-power paper electronics. Adv Sustain Syst. 2022;6(9):2200177. doi:10.1002/adsu.202200177. [Google Scholar] [CrossRef]

9. Agbakoba VC, Mokhena TC, Ferg EE, Hlangothi SP, John MJ. PLA bio-nanocomposites reinforced with cellulose nanofibrils (CNFs) for 3D printing applications. Cellulose. 2023;30(18):11537–59. doi:10.1007/s10570-023-05549-2. [Google Scholar] [CrossRef]

10. Chen S, Chen Y, Li D, Xu Y, Xu F. Flexible and sensitivity-adjustable pressure sensors based on carbonized bacterial nanocellulose/wood-derived cellulose nanofibril composite aerogels. ACS Appl Mater Interfaces. 2021;13(7):8754–63. doi:10.1021/acsami.0c21392. [Google Scholar] [PubMed] [CrossRef]

11. Yin R, Yang S, Li Q, Zhang S, Liu H, Han J, et al. Flexible conductive Ag nanowire/cellulose nanofibril hybrid nanopaper for strain and temperature sensing applications. Sci Bull. 2020;65(11):899–908. doi:10.1016/j.scib.2020.02.020. [Google Scholar] [PubMed] [CrossRef]

12. Rashid AB, Kafy A, Kabir N, Ishrak H, Rifat FF. Cellulose nanofibers/reduced graphene oxide nanocomposites for humidity sensor. Int J Polym Sci. 2024;2024(1):2937816. doi:10.1155/2024/2937816. [Google Scholar] [CrossRef]

13. Elkady MF, El-Sayed EM, Samy M, Koriem OA, Shokry Hassan H. Novel sustainable cellulose acetate-based biosensor for glucose detection. J Renew Mater. 2024;12(2):369–80. doi:10.32604/jrm.2023.046585. [Google Scholar] [CrossRef]

14. Chen X, Han X, Zhang C, Ou X, Liu X, Zhang J, et al. Synthesis of red, green, and blue carbon quantum dots and construction of multicolor cellulose-based light-emitting diodes. Small Structures. 2024;5(7):2300449. doi:10.1002/sstr.202470034. [Google Scholar] [CrossRef]

15. Sun S, Jia P, Lu M, Lu P, Gao Y, Zhong Y, et al. Enhanced flexibility and stability of emissive layer enable high-performance flexible light-emitting diodes by cross-linking of biomass material. Adv Funct Mater. 2022;32(33):2204286. doi:10.1002/adfm.202204286. [Google Scholar] [CrossRef]

16. Wu J, Che X, Hu HC, Xu H, Li B, Liu Y, et al. Organic solar cells based on cellulose nanopaper from agroforestry residues with an efficiency of over 16% and effectively wide-angle light capturing. J Mater Chem A. 2020;8(11):5442–8. doi:10.1039/c9ta14039e. [Google Scholar] [CrossRef]

17. Muddasar M, Beaucamp A, Culebras M, Collins MN. Cellulose: characteristics and applications for rechargeable batteries. Int J Biol Macromol. 2022;219:788–803. doi:10.1016/j.ijbiomac.2022.08.026. [Google Scholar] [PubMed] [CrossRef]

18. Zhang M, Du H, Liu K, Nie S, Xu T, Zhang X, et al. Fabrication and applications of cellulose-based nanogenerators. Adv Compos Hybrid Mater. 2021;4(4):865–84. doi:10.1007/s42114-021-00312-2. [Google Scholar] [CrossRef]

19. Sehaqui H, Allais M, Zhou Q, Berglund LA. Wood cellulose biocomposites with fibrous structures at micro- and nanoscale. Compos Sci Technol. 2011;71(3):382–7. doi:10.1016/j.compscitech.2010.12.007. [Google Scholar] [CrossRef]

20. Huang J, Zhou Y, Dong L, Zhou Z, Liu R. Enhancement of mechanical and electrical performances of insulating presspaper by introduction of nanocellulose. Compos Sci Technol. 2017;138:40–8. doi:10.1016/j.compscitech.2016.11.020. [Google Scholar] [CrossRef]

21. Hsieh M.C, Koga H, Suganuma K, Nogi M. Hazy transparent cellulose nanopaper. Sci Rep. 2017;7(1):41590. doi:10.1038/srep41590. [Google Scholar] [PubMed] [CrossRef]

22. Zeng J, Yan L. Metal-free transparent luminescent cellulose films. Cellulose. 2015;22:729–36. doi:10.1007/s10570-014-0485-y. [Google Scholar] [CrossRef]

23. Wang F, Wang W, Wang Y, Zhang L, Okamoto Y, Shen J. Cellulose/amylose derivatives bearing bulky substituents as reversible fluorescent sensors for detection of Fe3+. Carbohydr Polym. 2023;320:121249. doi:10.1016/j.carbpol.2023.121249. [Google Scholar] [PubMed] [CrossRef]

24. Grönroos P, Bessonoff M, Salminen K, Paltakari J, Kulmala S. Phosphorescence and fluorescence of fibrillar cellulose films. Nord Pulp Pap Res J. 2018;33(2):246–55. doi:10.1515/npprj-2018-3030. [Google Scholar] [CrossRef]

25. Nedilko S, Revo S, Nedielko M, Avramenko T, Ivanenko K, Scherbatskii V. Luminescence of the alkali-metals nitrites incorporated into cellulose matrix. Solid State Phenom. 2015;230:147–52. doi:10.4028/www.scientific.net/ssp.230.147. [Google Scholar] [CrossRef]

26. Patra SR, Mallick B. Structure and luminescence properties of CdSe/CdS-cellulose nanocomposites. J Mater Sci: Mater Electron. 2020;31:14101–7. doi:10.1007/s10854-020-03964-w. [Google Scholar] [CrossRef]

27. Lai Z, Ye J, Xiong J. Energy transfer processes and structure of carboxymethyl cellulose-Tb/Eu nanocomplexes with color-tunable photoluminescence. Carbohydr Polym. 2021;271:118386. doi:10.1016/j.carbpol.2021.118386. [Google Scholar] [PubMed] [CrossRef]

28. Skwierczyńska M, Stopikowska N, Kulpiński P, Kłonowska M, Lis S, Runowski M. Ratiometric upconversion temperature sensor based on cellulose fibers modified with yttrium fluoride nanoparticles. Nanomater. 2022;12(11):1926. doi:10.3390/nano12111926. [Google Scholar] [PubMed] [CrossRef]

29. Boyko V, Chornii V, Nedilko S, Terebilenko K. Luminescent converters based on nanocellulose+ K3Tb(PO4)2:Eu composite films. Mach Energ. 2023;2(14):80–9. doi:10.31548/machinery/2.2023.80. [Google Scholar] [CrossRef]

30. Hameed A, Aljuhani E, Bawazeer TM, Almehmadi SJ, Alfi AA, Abumelha HM, et al. Preparation of multifunctional long-persistent photoluminescence cellulose fibres. Luminescence. 2021;36(7):1781–92. doi:10.1002/bio.4123. [Google Scholar] [PubMed] [CrossRef]

31. El-Newehy M, El-Hamshary H, Abdul Hameed MM. Dual-mode security authentication of SrAl2O4:Eu,Dy phosphor encapsulated in electrospun cellulose acetate nanofibrous films. Luminescence. 2023;38(10):1758–67. doi:10.1002/bio.4562. [Google Scholar] [PubMed] [CrossRef]

32. Shi C, Hou X, Li X, Ge M. Preparation and characterization of persistent luminescence of regenerated cellulose fiber. J Mater Sci: Mater Electron. 2017;28:1015–21. doi:10.1007/s10854-016-5622-y. [Google Scholar] [CrossRef]

33. Zhang L, Lyu S, Chen Z, Wang S. Fabrication flexible and luminescent nanofibrillated cellulose films with modified SrAl2O4:Eu,Dy phosphors via nanoscale silica and aminosilane. Nanomater. 2018;8(5):352. doi:10.3390/nano8050352. [Google Scholar] [PubMed] [CrossRef]

34. Zhang L, Lyu S, Chen Z, Wang S. Preparation and characterization of dual-functional coatings of nanofibrillated cellulose and modified SrAl2O4:Eu,Dy phosphors. Surf Coat Technol. 2018;349:318–27. doi:10.1016/j.surfcoat.2018.05.071. [Google Scholar] [CrossRef]

35. Barbash VA, Yashchenko OV. Preparation, properties and use of nanocellulose from non-wood plant materials. In: Krishnamoorthy K, editor. Novel nanomaterials. London: IntechOpen; 2021. p. 61–83. doi:10.5772/intechopen.94272. [Google Scholar] [CrossRef]

36. Alekseev AN, Lazarenko MM, Lazarenko MV, Kovalev KN, Tkachev SY. Characterization of dielectric properties in liquid-solid phase transition. Inorg Mater. 2017;53:1473–7. doi:10.1134/s002016851715002x. [Google Scholar] [CrossRef]

37. Lazarenko MM, Hnatiuk KI, Alekseev SA, Yablochkova KS, Dinzhos RV, Ublekov F, et al. Low-temperature dielectric relaxation in the system silica gel-undecylenic acid. In: 2020 IEEE 10th International Conference Nanomaterials: Applications & Properties (NAP); 2020; New York City, NY, USA: IEEE. doi:10.1109/nap51477.2020.9309579. [Google Scholar] [CrossRef]

38. Zeng J, Zeng Z, Cheng Z, Wang Y, Wang X, Wang B, et al. Cellulose nanofibrils manufactured by various methods with application as paper strength additives. Sci Rep. 2021;11(1):11918. doi:10.1038/s41598-021-91420-y. [Google Scholar] [PubMed] [CrossRef]

39. Campano C, Merayo N, Balea A, Tarrés Q, Delgado-Aguilar M, Mutjé P, et al. Mechanical and chemical dispersion of nanocelluloses to improve their reinforcing effect on recycled paper. Cellulose. 2018;25:269–80. doi:10.1007/s10570-017-1552-y. [Google Scholar] [CrossRef]

40. Perdoch W, Cao Z, Florczak P, Markiewicz R, Jarek M, Olejnik K, et al. Influence of nanocellulose structure on paper reinforcement. Molecules. 2022;27(15):4696. doi:10.3390/molecules27154696. [Google Scholar] [PubMed] [CrossRef]

41. Azizi S, Ahmad MB, Ibrahim NA, Hussein MZ, Namvar F. Cellulose nanocrystals/ZnO as a bifunctional reinforcing nanocomposite for poly (vinyl alcohol)/chitosan blend films: fabrication, characterization and properties. Int J Mol Sci. 2014;15(6):11040–53. doi:10.3390/ijms150611040. [Google Scholar] [PubMed] [CrossRef]

42. Zhu T, Zuo X, Li Y, Zhang L, Xie D, Xiao X, et al. A novel membrane based on cellulose acetate nanofibers with a ZrO2 reinforcement layer for advanced sodium-ion batteries. J Membr Sci. 2021;620:118917. doi:10.1016/j.memsci.2020.118917. [Google Scholar] [CrossRef]

43. Hoffman JD, Williams G, Passaglia E. Analysis of the

44. Lazarenko MM, Alekseev AN, Alekseev SA, Yablochkova KS, Bokhvan SI, Demidiuk OF, et al. Topological solitons in aliphatic systems with a restricted translational mobility. Chem Phys. 2020;539:110959. doi:10.1016/j.chemphys.2020.110959. [Google Scholar] [CrossRef]

45. Lazarenko MM, Nedilko SG, Shevtsov DO, Scherbatskyi VP, Barbash VA, Yablochkova KS, et al. Dielectric and photoluminescent properties of the water-cellulose–NaCl systems in a wide range of temperatures: what is the role of ions? Springer Proc Phys. 2024;280:419–41. doi:10.1007/978-3-031-18104-7. [Google Scholar] [CrossRef]

46. Einfeldt J, Meißner D, Kwasniewski A. Polymerdynamics of cellulose and other polysaccharides in solid state-secondary dielectric relaxation processes. Progr Polym Sci. 2001;26(9):1419–72. doi:10.1016/S0079-6700(01)00020-X. [Google Scholar] [CrossRef]

47. Erdmann R, Kabasci S, Heim HP. Thermal properties of plasticized cellulose acetate and its β-relaxation phenomenon. Polymers. 2021;13(9):1356. doi:10.3390/polym13091356. [Google Scholar] [PubMed] [CrossRef]

48. Gong Y, Tan Y, Mei J, Zhang Y, Yuan W, Zhang Y, et al. Room temperature phosphorescence from natural products: crystallization matters. Sci China Chem. 2013;56(9):1178–82. doi:10.1007/s11426-013-4923-8. [Google Scholar] [CrossRef]

49. Ge M, Liu S, Li J, Li M, Li S, James TD, et al. Luminescent materials derived from biomass resources. Coord Chem Rev. 2023;477:214951. doi:10.1016/j.ccr.2022.214951. [Google Scholar] [CrossRef]

50. Lazarenko MM, Alekseev OM, Kondratenko SV, Kovalchuk VI, Nedilko SG, Sherbatskii VP, et al. Physical-chemical properties of nanocellulose synthesized from Miscanthus x Giganteus. Mol Cryst Liq Cryst. 2024;768(1):42–56. doi:10.1080/15421406.2023.2231263. [Google Scholar] [CrossRef]

51. Matsuzawa T, Aoki Y, Takeuchi N, Murayama Y. A new long phosphorescent phosphor with high brightness, SrAl2O4:Eu2+, Dy3+. J Electrochem Soc. 1996;143:2670–3. doi:10.1002/chin.199649270. [Google Scholar] [CrossRef]

52. Dorenbos P. Absolute location of lanthanide energy levels and the performance of phosphors. J Lumin. 2007;122:315–7. doi:10.1016/j.jlumin.2006.01.155. [Google Scholar] [CrossRef]

53. Clabau F, Rocquefelte X, Jobic S, Deniard P, Whangbo MH, Garcia A, et al. On the phosphorescence mechanism in SrAl2O4:Eu2+ and its codoped derivatives. Solid State Sci. 2007;9:608–12. doi:10.1016/j.solidstatesciences.2007.03.020. [Google Scholar] [CrossRef]

54. Aitasalo T, Hölsä J, Jungner H, Lastusaari M, Niittykoski J. Thermoluminescence study of persistent luminescence materials: Eu2+- and R3+-doped calcium aluminates, CaAl2O4:Eu2+,R3+. J Phys Chem B. 2006;110:4589–98. doi:10.1021/jp057185m. [Google Scholar] [PubMed] [CrossRef]

55. Murayama Y, Watanabe S, Akase M, Matsui K. Effects of composition and reduction conditions on persistent luminescence of SrAl2O4:Eu,Dy prepared via a solid-state reaction. J Lumin. 2022;251:119248. doi:10.1016/j.jlumin.2022.119248. [Google Scholar] [CrossRef]

56. Ruiz-Torres R, Chernov V, Salas-Castillo P, Zúñiga-Rivera NJ, Diaz-Torres LA, Meléndrez R, et al. Effect of thermal treatment on luminescence properties of long persistent CaAl2O4:Eu2+,Dy3+ synthesized by combustion method. Opt Mater. 2020;101:109763. doi:10.1016/j.optmat.2020.109763. [Google Scholar] [CrossRef]

57. Hoang K. Defects and persistent luminescence in Eu-doped SrAl2O4. Phys Rev Appl. 2023;19(2):024060. doi:10.1103/PhysRevApplied.19.024060. [Google Scholar] [CrossRef]

58. Shi D, Wang Y, Yang N, Li F, Li X, Ye J, et al. Synthesis of a CaAl2O4:Eu2+, Dy3+ phosphor by the polymer slurry method and its application in anticounterfeiting. Ind Eng Chem Res. 2023;62:3465–76. doi:10.1021/acs.iecr.2c03708. [Google Scholar] [CrossRef]

59. Aroz R, Lennikov V, Cases R, Sanjuán ML, de la Fuente GF, Munoz E. Laser synthesis and luminescence properties of SrAl2O4:Eu2+, Dy3+ phosphors. J Eur Ceram Soc. 2012;32(16):4363–9. doi:10.1016/j.jeurceramsoc.2012.06.013. [Google Scholar] [CrossRef]

60. McCamy CS. Correlated color temperature as an explicit function of chromaticity coordinates. Color Res Appl. 1992;17(2):142–4. doi:10.1002/col.5080170211. [Google Scholar] [CrossRef]

61. Chornii V, Terebilenko K, Gural’skiy I, Slobodyanik M, Zozulia V, Shova S, et al. Structural and spectroscopic insights into the performance of K3Tb(PO4)2 green phosphor. Dalton Trans. 2024;53(37):15583–94. doi:10.1039/d4dt01816h. [Google Scholar] [PubMed] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools