Open Access

Open Access

ARTICLE

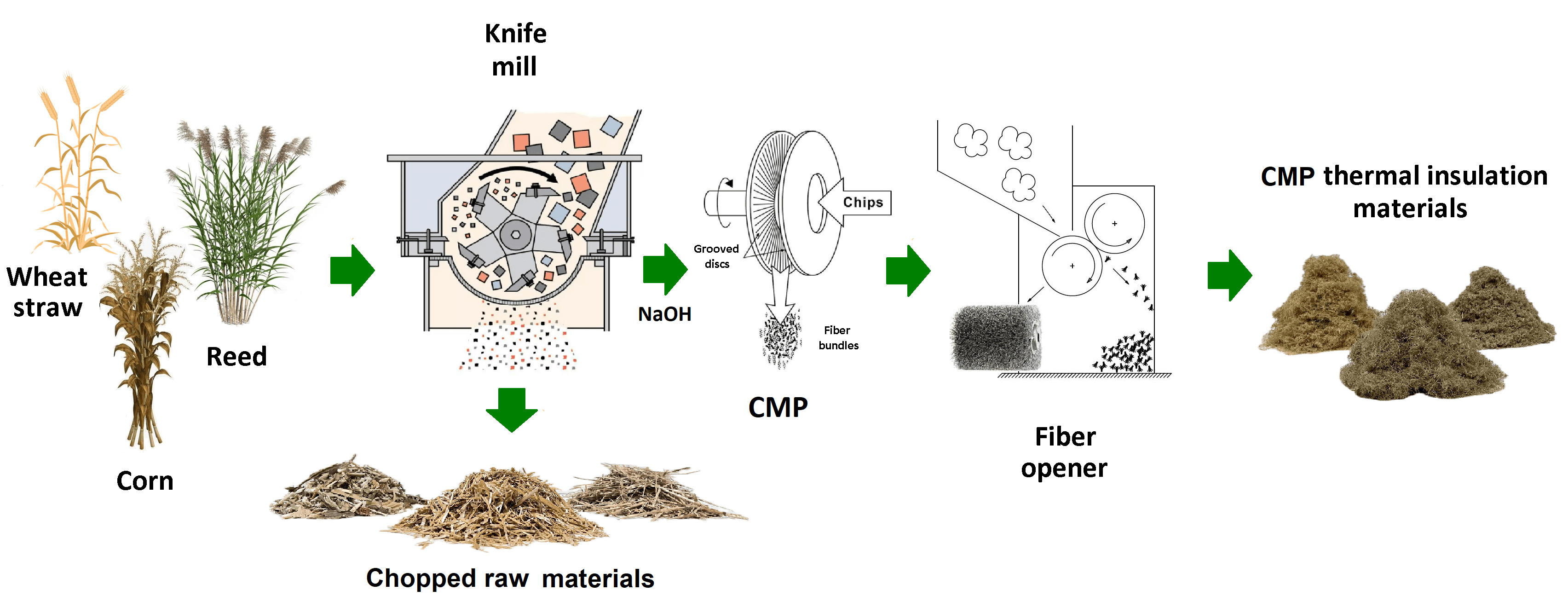

Development of Loose-Fill Thermal Insulation Materials from Annual Plant Residues Using Low-Concentration Chemimechanical Pulping

1 Latvian State Institute of Wood Chemistry, Riga, LV-1006, Latvia

2 Latvia University of Life Sciences and Technologies, Jelgava, LV-3001, Latvia

* Corresponding Author: Ramunas Tupciauskas. Email:

Journal of Renewable Materials 2025, 13(6), 1189-1207. https://doi.org/10.32604/jrm.2025.02024-0067

Received 21 December 2024; Accepted 29 April 2025; Issue published 23 June 2025

Abstract

This study examines the development of loose-fill thermal insulation materials derived from annual plant residues, such as wheat straw, water reeds, and corn stalks, processed using the chemimechanical pulping (CMP) technique. The chopped plants were soda-cooked for 30 min, varying NaOH concentration (2%–8% on a dry basis of biomass), and mechanically refined using different disc types. The CMP process enhances the homogeneity and stability of defibrated material, yielding improved insulation properties compared to untreated chopped raw materials. Chemical analysis revealed that CMP increases cellulose content and reduces lignin levels, enhancing water retention and vapor diffusion properties. Settlement tests confirmed that CMP materials are more resistant to compaction under vibration, maintaining long-term performance. Additionally, the CMP enables the production of lightweight materials that require less resource consumption while achieving comparable thermal insulation performance. The investigated bio-based materials offer a sustainable alternative to conventional insulation, with competing thermal conductivity values (0.041–0.046 W/mK) at the settlement-resistant bulk density level of 60 kg/m3. The thermal conductivity of CMP materials remains minimally affected. However, the resulting fibers demonstrate significant advantages in stability and material efficiency. This highlights its suitability for loose-fill applications to improve the sustainability of the construction. Using renewable plant residues, CMP-based insulation materials align with circular economy principles and contribute to environmental sustainability. This research underscores the potential of CMP materials to reduce greenhouse gas emissions, optimize resource use, and promote eco-friendly building practices.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools