Open Access

Open Access

ARTICLE

Development of Loose-Fill Thermal Insulation Materials from Annual Plant Residues Using Low-Concentration Chemimechanical Pulping

1 Latvian State Institute of Wood Chemistry, Riga, LV-1006, Latvia

2 Latvia University of Life Sciences and Technologies, Jelgava, LV-3001, Latvia

* Corresponding Author: Ramunas Tupciauskas. Email:

Journal of Renewable Materials 2025, 13(6), 1189-1207. https://doi.org/10.32604/jrm.2025.02024-0067

Received 21 December 2024; Accepted 29 April 2025; Issue published 23 June 2025

Abstract

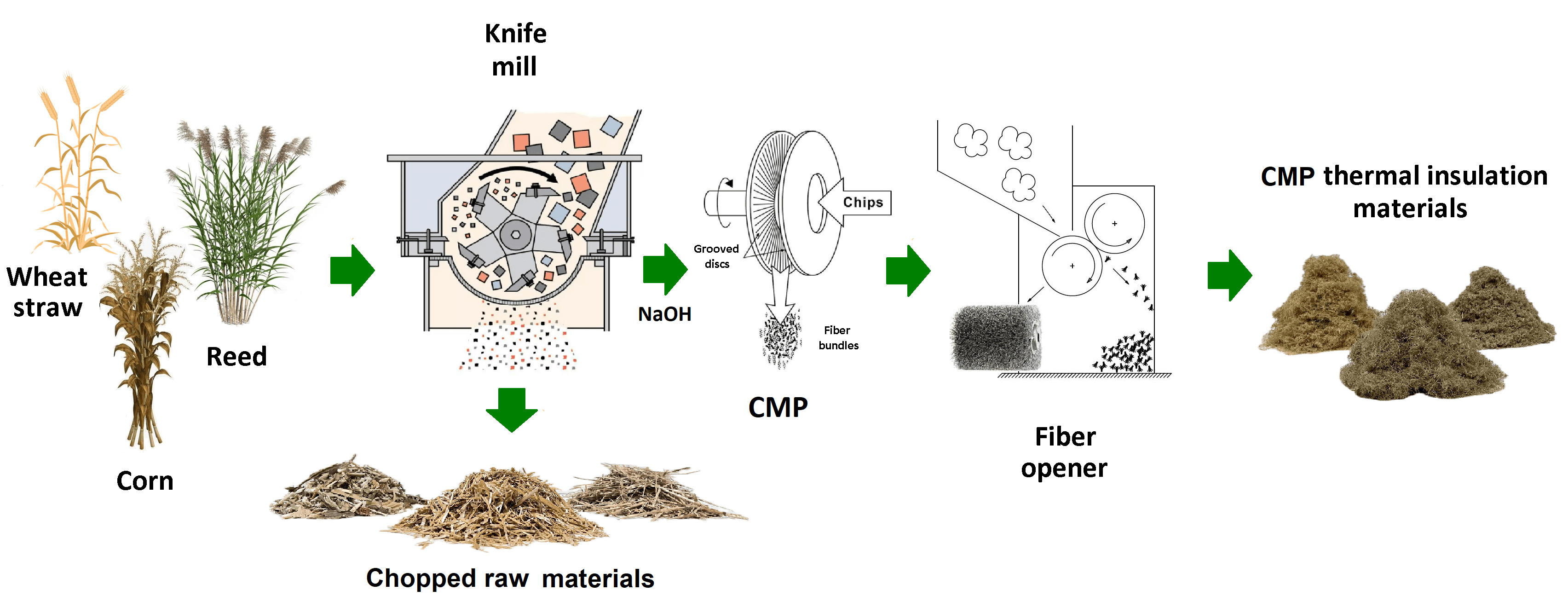

This study examines the development of loose-fill thermal insulation materials derived from annual plant residues, such as wheat straw, water reeds, and corn stalks, processed using the chemimechanical pulping (CMP) technique. The chopped plants were soda-cooked for 30 min, varying NaOH concentration (2%–8% on a dry basis of biomass), and mechanically refined using different disc types. The CMP process enhances the homogeneity and stability of defibrated material, yielding improved insulation properties compared to untreated chopped raw materials. Chemical analysis revealed that CMP increases cellulose content and reduces lignin levels, enhancing water retention and vapor diffusion properties. Settlement tests confirmed that CMP materials are more resistant to compaction under vibration, maintaining long-term performance. Additionally, the CMP enables the production of lightweight materials that require less resource consumption while achieving comparable thermal insulation performance. The investigated bio-based materials offer a sustainable alternative to conventional insulation, with competing thermal conductivity values (0.041–0.046 W/mK) at the settlement-resistant bulk density level of 60 kg/m3. The thermal conductivity of CMP materials remains minimally affected. However, the resulting fibers demonstrate significant advantages in stability and material efficiency. This highlights its suitability for loose-fill applications to improve the sustainability of the construction. Using renewable plant residues, CMP-based insulation materials align with circular economy principles and contribute to environmental sustainability. This research underscores the potential of CMP materials to reduce greenhouse gas emissions, optimize resource use, and promote eco-friendly building practices.Graphic Abstract

Keywords

Today’s dynamic changes influenced by human activity affect the comfort of our lives and the environment. To improve the quality of life and reduce the negative impact on nature, it is essential to use resources wisely to produce environmentally friendly materials. Thermal insulation materials derived from local and renewable resources can provide the desired indoor climate comfort, simultaneously reducing greenhouse gas (GHG) emissions [1]. Building energy efficiency is one of the main factors promoting GHG reduction. The construction sector consumes between 30% and 40% of global energy and produces one-third of the world’s GHG emissions [1,2]. Effective thermal insulation is essential to reduce energy consumption for building heating and cooling, ensuring a comfortable indoor temperature. To support decarbonization efforts, the World Green Building Council has set the goal of achieving net-zero carbon emissions by 2050 [3]. Likewise, the European Commission’s stringent stance on limiting GHG emissions and its commitment to the European Green Deal requires a shift towards using and applying renewable resources of lignocellulosic biomass (LCB) responsibly [4]. The construction industry distinguishes between two types of carbon emissions: embodied carbon, which arises during the production and transportation of materials, and operational carbon, which is related to building energy consumption. Currently, the ratio of these emissions is 42:58; however, the Committee on Climate Change aims to shift this to 68:32 by 2030 [5]. This indicates a need for low-emission materials that reduce energy use for building maintenance. The use of LCB-based thermal insulation in Europe reached only 2% in 2022. After the Environmental Regulation and Responsible Building Regulation in 2020, the application of LCB-based thermal insulation in France is expected to get 13% by 2030 [6].

The primary function of thermal insulation materials is to separate building structures from the external environment and to reduce the heat flow, ensuring a comfortable indoor microclimate. Insulation efficiency is mainly characterized by thermal conductivity, where a lower value indicates better insulation properties. The lower the material’s thermal conductivity, the thinner the insulation layer is required to maintain the same indoor temperature, indicating the better insulator [7,8]. The structure of plants has a unique thermal insulation property, making them suitable for producing insulation material [9,10]. Previous studies on using annual plants for loose-fill insulation through the steam explosion technique have shown thermal conductivity values ranging from 0.04 to 0.05 W/mK [11]. The thermal insulation properties of wheat straw and corn husk have demonstrated promising results using a pulping method, indicating their suitability for insulation material development [12]. The recycling of LCB residues has traditionally been considered for paper production and fiberboard manufacturing [13–16]. However, studies on the hygro-thermal performance of loose-fill LCB for insulation applications are limited [17,18]. Plant-based LCBs are well-suited for fiber extraction from various parts, such as bast, leaves, stems, seeds, fruits, and grasses [19]. Depending on the plant species, fiber length can vary from less than a millimeter to several tens of millimeters [20]. Plants rich in long fibers, such as hemp, flax, and jute, are typically used for insulation materials in construction [18,21,22], although these fibers are used mainly in textiles [23] and rope production [24].

Various methods can be applied to process plant residues with short fiber lengths into fibrous materials suitable as loose-fill building insulation. Unlike perennial wood, annual plants contain less lignin, making it easier to refine even at low temperatures and fewer chemicals. Smaller mill sizes and a simplified process can also be economically beneficial [25]. While the structure of plants is similar to wood, their specific characteristics require less energy for fiber extraction. In turn, the lifecycle of annual plants, especially residues of agriculture crops, allows much faster material resource availability compared to the wood [19]. The most widely used fiber extraction techniques are thermomechanical pulping, chemical thermomechanical pulping, alkaline peroxide mechanical pulping, and steam explosion pulping [11,26]. Both chemical/thermomechanical pulping are typically used for fiber extraction in paper and packaging production [25,27,28], while the extraction of non-wood short fibers for insulation applications is less studied [18]. A refiner can mechanically separate fibers; however, to improve the process, a pre-treatment with chemicals such as NaOH is used to facilitate the defibration process [13,29].

The existing research indicates that plant-based LCB is an available resource that could be suitable for thermal insulation purposes because it exhibits low thermal conductivity [9–11,30–32]. Plant-based insulation aims not to obtain individual fibers but rather a fibrous loose-fill mass with a low density. Considering those mentioned above, this study examines the potential of using annual plants to develop thermal insulation materials, offering solutions for sustainable construction. Fiber extraction by low-concentration chemical-mechanical pulping was reviewed to develop and evaluate loose-fill insulation materials from locally available plant residues—wheat straw, corn stalk, and water reed.

The study utilized three locally sourced (Latvia) plant residues: wheat (Triticum aestivum) straw (WS), water reeds (Phragmites australis) (WR), and corn (Zea mays) stalks (CS). The wheat straw was collected from a farmer in Limbazi district; water reeds were harvested in winter from a lake Puze, Ventspils district; and fresh corn stalks were obtained in late September from a farm “Pauri” in Blome. Each raw material was chopped separately using a knife mill (CM4000, LAARMANN, Roermond, Netherlands), with sieving at Ø 30 mm and Ø 20 mm, providing consistent particles suitable for further processing.

2.2 Preparation of Chopped Insulation Materials

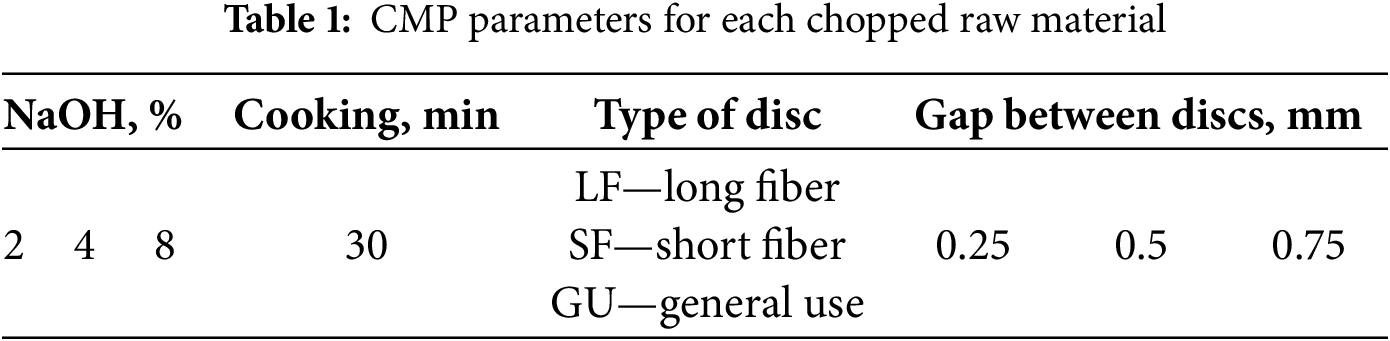

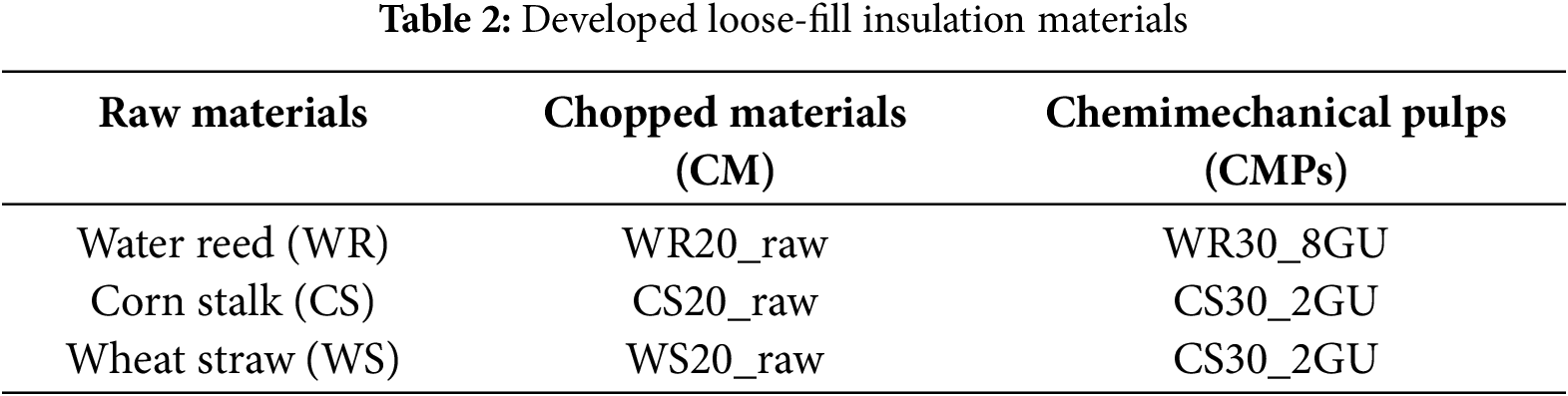

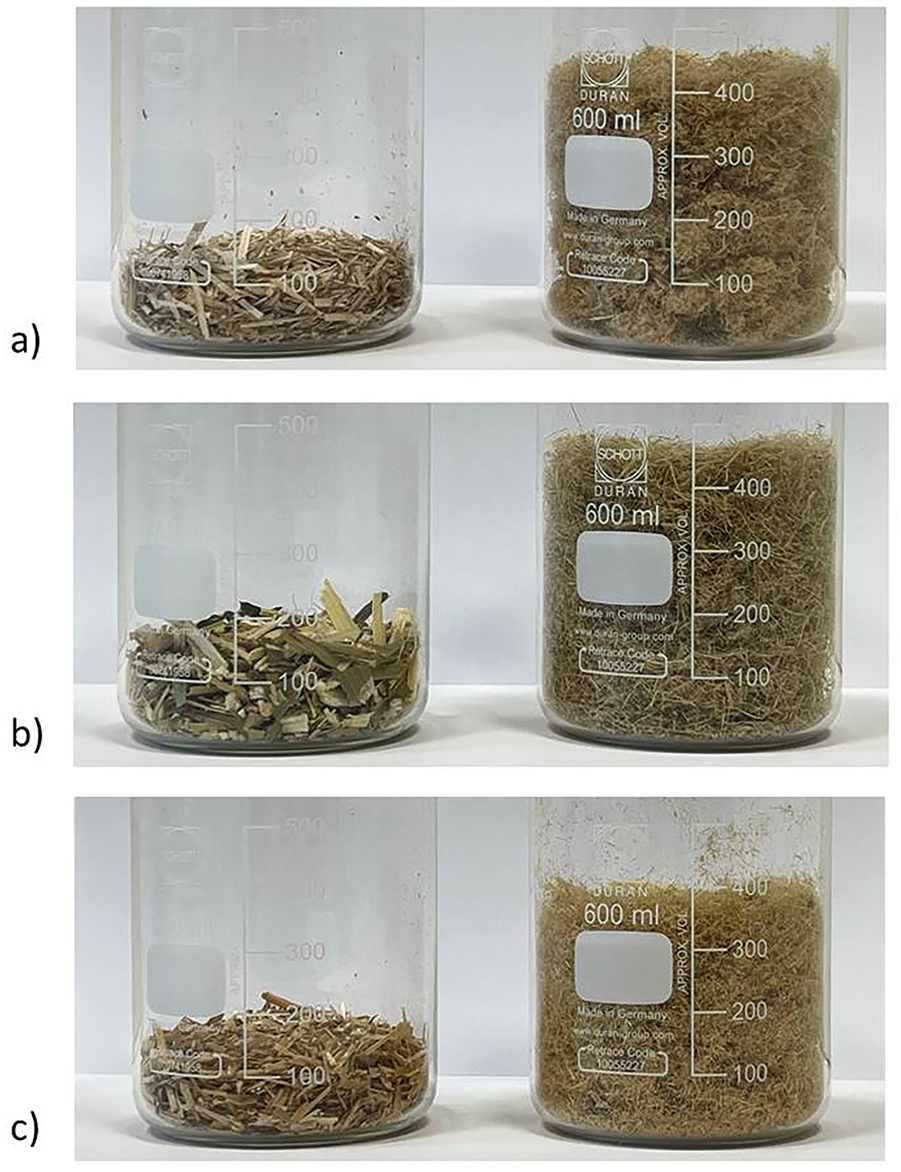

To prepare chopped loose-fill insulation materials, each raw plant species was chopped using a knife mill equipped with a 20 mm sieve to make the material homogeneous and suitable for blowing technology. The obtained chopped insulation materials (CMs) from reeds (WR20_raw), wheat straw (WS20_raw), and corn stalks (CS20_raw) were used as reference samples for comparison with CMP samples.

2.3 Preparation of Insulation Materials by CMP

Before mechanical pulping by a disc refiner (REGMED MD-3000) in a water medium, the chopped raw materials (Ø 30 mm) were cooked (100) for 30 min with the addition of sodium hydroxide (NaOH) varying concentrations (2%, 4%, and 8%) relative to the dry weight of the material. The proportion of CM and water was about 1:28. The cooked samples were drained through a metal sieve (3 mm) and then introduced in small portions (30–50 g) into a refining tank containing 10 L of water, varying with three discs and a gap between them. The parameters of CMP are summarized in Table 1. During the mechanical pulping, the discs were gradually brought closer to reach the desired spacing, with each run lasting between 10 and 20 min.

The obtained CMP was strained through two sieves with 2.5 and 1.25 mm openings to improve drainage. The strained fiber mass was then hand-compressed to remove the residual water, achieving a moisture content of 70 ± 10%. The drained fiber mass was foamed/homogenized using a mechanical loosening device consisting of a system of two rotating cylinders (900 rpm) coupled with stainless steel wires, ensuring uniform fiber dispersion [11]. This fluffing and partially drying process was repeated up to 5 times. Finally, the CMP was oven-dried at 45°C–60°C and conditioned at 20 ± 2°C and a relative humidity of 60 ± 5%.

2.4 Characterization of Insulation Materials

2.4.1 Determination of Chemical Composition

Chemical components in terms of cellulose (glucan), hemicellulose (a combination of xylan, galactan, mannan, arabinan, and acetyl groups), lignin, and ash of CM and CMP samples were determined based on the Laboratory Analytical Procedures detailed in the standards NREL/TP-510-42618 and NREL/TP-510-42622 [33,34].

2.4.2 Determination of Particle Size Distribution

The particle size distribution of developed insulation materials was determined using a sieve column (Haver & Boecker, Oelde, Germany) with mesh sizes of 0.5, 1.0, 2.0, 3.15, 5.0, and 10 mm, according to EN 15149-1, sieving time 3 min [35].

2.4.3 Application of Light Microscopy

To assess the defibrillation of the obtained CMP, samples were placed in an open container with the target bulk density of 60 kg/m3 and examined with a Zeiss Stemi 508 stereomicroscope (Carl Zeiss Microscopy GmbH, Jena, Germany) using a dual-point illumination and magnifications of 2× and 10×.

2.4.4 Determination of Water Retention Value (WRV)

To determine WRV, untreated raw materials were chopped to pass a 6 mm sieve to fit within test tubes. Then, both CM and CMP samples were soaked in water for 24 h, transferred to pre-weighed dry tubes, and centrifuged at 4500 rpm for 15 min before drying at 105°C. The percentage of WRV was calculated from the Eq. (1):

where m1 and m2 are the sample’s mass before and after drying.

2.4.5 Determination of Water Vapor Diffusion Resistance

The water vapor diffusion resistance coefficient μ of CM and CMP samples was determined by the standard EN 12086 [36]. The testing vessel consists of a cylindrical container with a dehydrating agent placed at the bottom, an air gap, a metal mesh to support the loose material, and the test material positioned at the top. To prepare the testing vessel, 225 g of phosphorus pentoxide (P2O5) is introduced at the bottom of a cylindrical container with an internal diameter of 105 mm. A metal mesh supports the test material 20 mm above the dehydrating agent. The test material is placed at a thickness of 50 mm, with a density of 60 kg/m3 or a specified compacted density. Before testing, the material was conditioned at 20 ± 2°C and a relative humidity of 60 ± 5%.

The prepared testing vessel was placed in a climate chamber set to a temperature of 23 ± 1°C and a relative humidity of 85 ± 3%. The sample mass was measured every 24 h until the mass change over a defined interval reached a stable rate of ±5%. Water vapor diffusion resistance μ is calculated from the Eq. (2):

where δair is the water vapor permeability of air, which at atmospheric pressure of 1013 hPa is 0.71 mg/(m·h·Pa), and δ is the water vapor permeability of the sample, expressed in mg·m/h·Pa. The water vapor permeability δ is derived from Eq. (3):

where d represents the thickness of the test sample in meters, and W is the water vapor conductance in mg·m2/h·Pa. Water vapor conductance W is defined by the Eq. (4):

where Δp represents the water vapor pressure differential, calculated as 2390 Pa under the specified test conditions, A is the exposed area of the sample (m2), and G denotes the hourly mass change rate (mg/h).

2.4.6 Determination of Bulk Density

The bulk density of developed loose-fill insulation materials was measured according to the standard EN 15103 [37]. The material was poured into a 5-L cylindrical metal container, tapped three times to settle, refilled, and weighed. The bulk density of the samples with the air-dry moisture content (Dar) was calculated from the Eq. (5):

where m1 and m2 are the empty and the filled container mass (kg), accordingly, and V is the container volume (m3). The measurement was repeated five times to establish an average value.

2.4.7 Determination of Thermal Conductivity

The thermal conductivity of developed materials was determined according to the standard ISO-8301 using a LINSEIS Heat Flow Meter 200 (RobMaterials, Robbinsville, NJ, USA). Samples with a constant thickness of 50 mm, varying density from bulk to 90 kg/m3 were placed in a container with the inner measurements of 200 mm × 200 mm × 50 mm, and the coefficient of thermal conductivity λ measured between 0°C and 20°C.

2.4.8 Determination of Settling

Settling of loose-fill insulation materials was tested according to the standard EN 15101-1+A1:2019 [38] using a box with the inner measurements of 2300 mm × 600 mm × 100 mm fixed within a frame accomplished with an eccentric motor (2800 rpm). The conditioned (20 ± 2°C, RH 60 ± 5%) samples were blown into the box by a cellulose blower Krendl (Model 575, Krendl, Delphos, OH, USA) to achieve the required density by changing the material feed opening and airflow. After an initial sample installation, the motor vibrated vertically-fixed box for at least 30 min. The height of any settled material was recorded, and the additional material was blown in until no further settling was observed. Finally, the density of settled materials was calculated according to the weighted mass.

The factors influencing the mean values using the standard deviation of at least three individual specimens of the tested properties described above were analyzed by Excel software using the one-way ANOVA tool at the significance level α = 0.05.

3.1 Impact of CMP Parameters on Developed Insulation Materials

In general, variations in NaOH concentration, type of disc, and gap between the discs impacted both bulk density and thermal conductivity of obtained CMP samples. The determined bulk density for WR ranged from 24.6 to 97.9 kg/m3, CS from 19 to 34 kg/m3, and WS from 16.2 to 79 kg/m3. At the same time, the determined thermal conductivity for WR ranged from 0.044348 to 0.05052 W/mK, for CS from 0.04059 to 0.04824 W/mK, and for WS from 0.04285 to 0.05267 mW/mK.

The pre-treatment of biomass in the NaOH solution facilitates moisture absorption, which enhances biomass particle size reduction during defibrillation in a refiner. The increase of NaOH concentration to 8% significantly improved the defibrillation of reeds. However, the highest NaOH concentration for wheat straw and corn samples resulted in high defibrillation and increased fine particles sticking together into balls. Consequently, this increased the density and thermal conductivity of the obtained materials. For wheat straw and corn samples, an increase in NaOH concentration from 2% to 4% leads to an increase in thermal conductivity while reducing bulk density, regardless of the refining disc type and gap. In contrast, bulk density and thermal conductivity decreased with increasing NaOH concentration for reed samples.

The CMP process’s feasibility primarily determines the disc type’s influence on the resulting fiber. For instance, the biomass was inadequately processed using the SF disc, resulting in the fiber sticking during the process. Conversely, the LF disc produced more irregular fiber shapes with a higher bulk density. The GU disc was the most suitable for fiber extraction from selected biomass species, as it exhibited acceptable bulk density and thermal conductivity values while ensuring a more uniform refining process.

The gap between the refining discs affected the thickness of the fiber bundle. Given that the target fiber should be thin and long, providing a higher aspect ratio, the smaller gap resulted in more optimal fiber extraction. The provided tests showed that a reduced gap decreased the bulk density and thermal conductivity of developed insulation materials.

A decrease in the amount of dry mass can be observed during NaOH treatment and defibrillation. After the soda cooking, mineral particles and dissolved compounds are partially washed off during the draining. During defibrillation in a refiner, additional small particles are formed, which are further filtered through a sieve. Reducing the mesh size could reduce the loss of these particles, but since the fine fraction is not desirable for the insulation material, reducing this loss is unnecessary. The amount of useful dry mass during processing decreases depending on the type of plant and the processing parameter. For example, the dry matter reduction for WR and CS pulps is between 26% and 38%, but for WS, it’s between 20% and 26%. Possibly, the better results of annual plant defibration could be achieved by conducting a mechanical pulping in a steam/pressure refiner combined with a flash tube dryer [39,40]. This approach could eliminate the need for NaOH usage and wastewater management during CMP, while flash drying could reduce the proportion of hydrogen-bonded fibers and enhance thermal insulation performance.

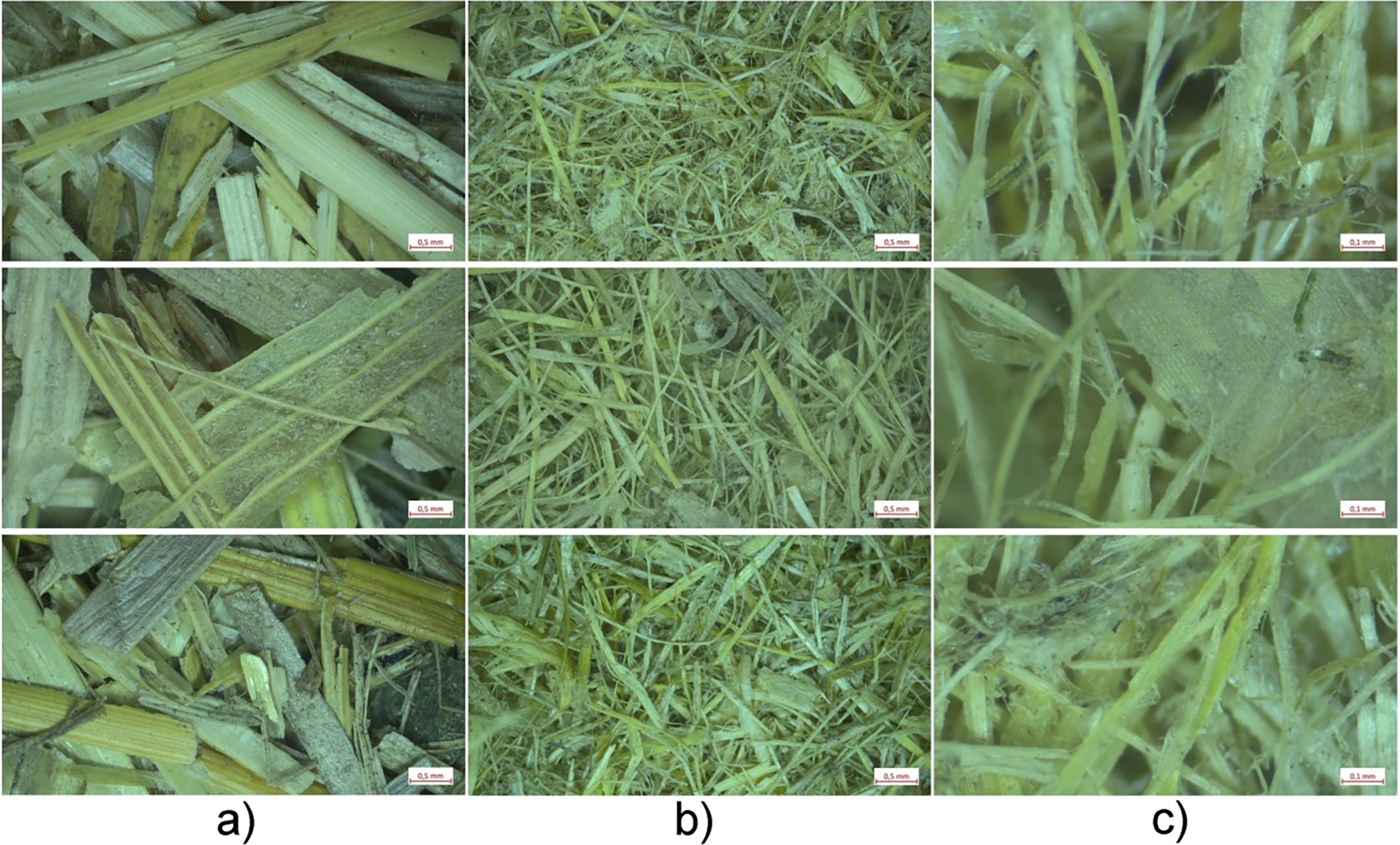

Based on the conclusions derived from the performed CMP experiments followed by initial tests, a further comprehensive examination will be focused on three CMP samples obtained by GU discs through the gap of 0.25 mm. As was mentioned above, an optimal NaOH concentration for water reeds was 8%, and the sample was designated as WR30_8GU. An optimal NaOH concentration for wheat straw and corn stover was 2%, and the samples were designated as WS30_2GU and CS30_2GU, respectively. The summary and pictures of investigated loose-fill insulation samples are given in Table 2 and Fig. 1, respectively.

Figure 1: Pictures of CM (left) and CMP (right) loose-fill insulation samples (10 g per sample) from water reed (a), corn stalk (b), and wheat straw (c)

3.2 Properties of Developed Loose-Fill Insulation Materials

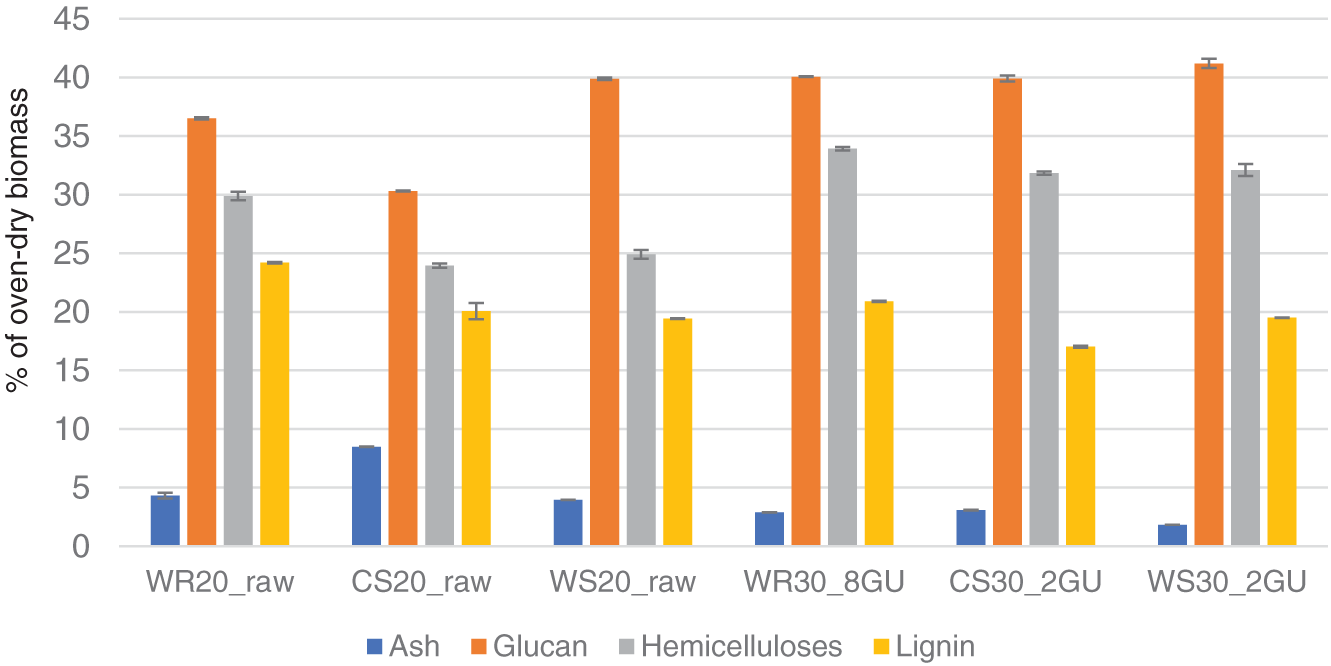

3.2.1 Analysis of Chemical Composition

The chemical composition of raw and CMP samples is illustrated in Fig. 2. After CMP, the ash content of all plant species decreased, which can be attributed to the leaching of mineral particles during the fiber drainage. The highest ash content between raw species was found in CS20_raw (8.45%), which decreased to 3.08% in CMP. The lowest ash content between raw species was detected in WS20_raw (3.95%), dropping to 1.84% in CMP. Like ash, lignin content also decreased in CMP samples (except for WS), which can be attributed to the cooking in NaOH solution. In contrast, the cellulose and hemicellulose contents increased in all CMP samples. These results are in line with other works reviewed by Worku et al. [41].

Figure 2: Chemical composition of raw and CMP samples

3.2.2 Analysis of Light Microscopy

Examination of LCB samples using light microscopy revealed that plant materials after CMP are fragmented, primarily forming fiber bundles parallel to the grain (Fig. 3). The material does not yield single fiber structures. At magnification of 10×, the outer edges of the fiber bundles show thinner fiber segments; however, individual fibers are not obtained during CMP. Such result is related to relatively low NaOH content, which usually contains 15%–50% solution in the case of the pulp and paper industry [41]. During the CMP, the number of particles increases while maintaining the same pore size, reducing the bulk density. For a given volume, it is likely to be greater.

Figure 3: Microscopical surface view of WR (above), CS (middle), and WS (bottom) samples: (a) raw (scale bars 0.5 mm), (b) CMP 2

Comparing the fiber bundles obtained by the SE technique [11], the CMP fiber bundles are straighter and only partially curved, which is different from SE fibers. No significant differences were observed by the light microscopy between the CMP samples in terms of used LCB species. A slightly finer fiber agglomeration was noted in the reed sample at a magnification of 2×, promoting inter-particle adhesion. This correlates with the particle size distribution overviewed in the following subsection (the proportion of fiber fractions above 10 mm is 61%, while the particles below 0.5 mm contain only 8%). This suggests that the blown-in material in a construction may resist the settlement well.

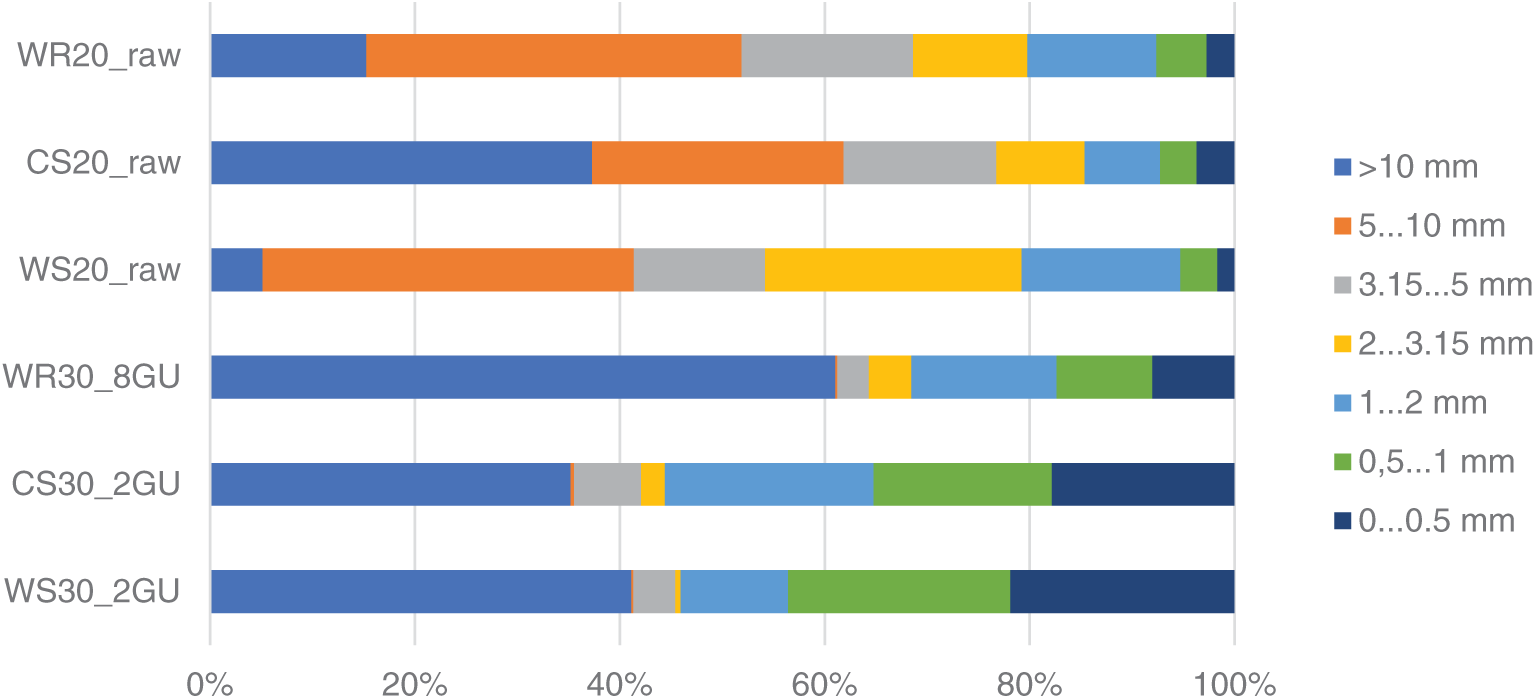

3.2.3 Analysis of Particle Size Distribution

The results of the particle size distribution of CM and CMP samples are summarized in Fig. 4. The particle size distribution of corn stalk and wheat straw CMP samples is relatively similar, accounting for the particles below 2 mm for 55.6% and 54.1%, respectively. In contrast, the reed CMP sample accounts for only 31.5% of the size fraction below 2 mm, which can be attributed to a more pronounced particle agglomeration (adhesion between fibers) above the 10 mm sieve. The fraction between 5 and 10 mm of CM and CMP samples significantly decreased from an average of 32% to 0.2%, respectively. This indicates that the CMP effectively reduces the diameter of the fractions. Concurrently, during the drying, the fiber agglomeration occurs due to the hydrogen bonding [42], increasing particle fraction greater than 10 mm (Fig. 3). There is a notable increase in the particles within the 2 mm fraction, demonstrating the impact of CMP on the quantity of defibrated particles.

Figure 4: Distribution of LCB particle size depending on the processing

The particle distribution of CMP obtained during this study is somewhat similar to the pulp obtained by steam explosion [11]. The volume of particle fraction between 2 and 10 mm is significantly reduced, but the fractions of fines and particles above 10 mm increase. It is clear that the processing does not directly increase the particle size but rather makes the adhesion or sticking of fine particles, which form a larger particle cluster. Such particle formation can reduce the stratification of fractions, at the same time, it can also affect the density of the material.

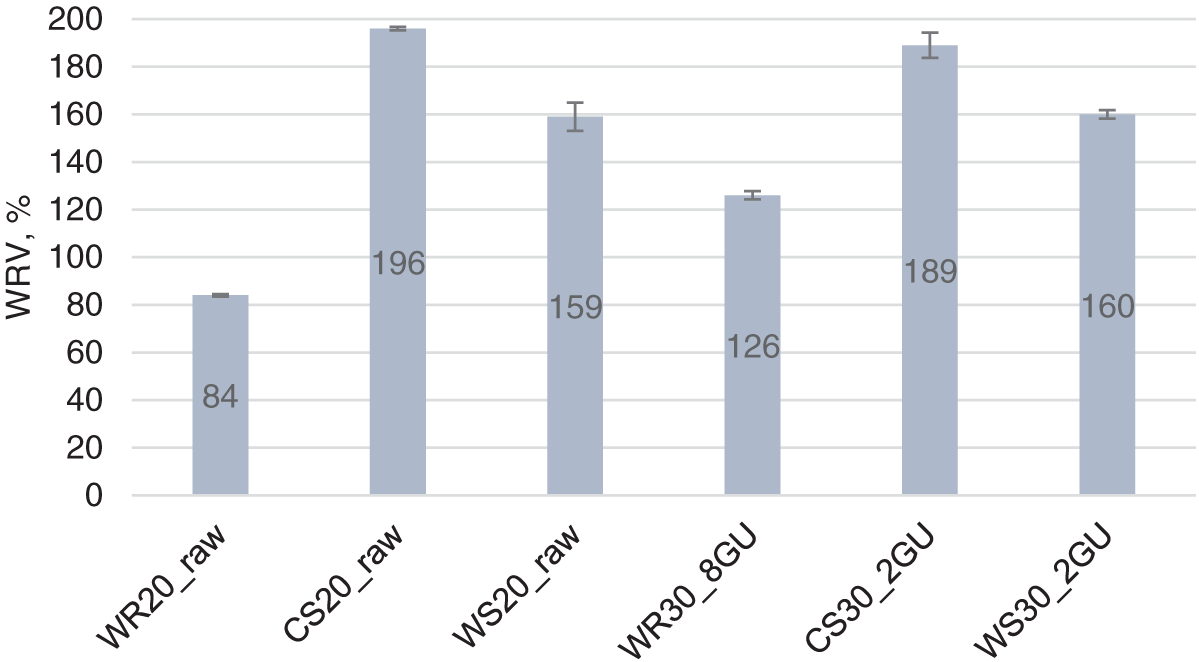

3.2.4 Analysis of Water Retention Value (WRV)

The WRV allows assessing the material’s ability to retain and release water. Factors influencing this include the material’s porosity, cell wall composition, surface smoothness, particle size, and other properties. WRV is a critical parameter for thermal insulation materials, as an increase in moisture content elevates its thermal conductivity [43]. Increased moisture also affects the risks of fungal growth.

WRV results of developed loose-fill insulations are shown in Fig. 5. The CMP showed a relatively little effect on the WRV of wheat straw and corn samples, achieving approximately 160% and 190%, respectively. In contrast, the WRV of reed samples significantly increased from 84% to 126%. Typically, the WRV increases after the CMP because it increases the surface area of the fibers and the number of micropores by disrupting the cell walls [44–47]. Little changes in WRV of wheat straw and corn samples after CMP could be related to the low NaOH content used (2% on dry LCB). In the case of reed samples, NaOH content was 8%, which resulted in a significant increase in WRV. The lower WRV of reed compared to corn and wheat samples could also be related to the natural water absorption resistance because of the exceptional growing conditions in an aquatic environment.

Figure 5: Water retention value of LCB

To compare, the reported WRV of untreated hardwoods like birch and poplar are 71% and 79%, respectively [48], of date palms, 138% [45], rice straw after TMP 118% [49] and conifers around 110%, which increases with a processing degree [50].

In general, it could be said that the WRV of different LCBs depends on many factors, including chemical changes. It was observed that a higher content of cellulose and hemicellulose increases WRV, while lignin, being hydrophobic, decreases it [11,51]. In our case, the explanation could be attributed only to the reed samples, in which lignin content decreases, but the contents of hemicelluloses and cellulose increase after CMP (Fig. 1). Despite WRV variations within the developed CMP insulations, all samples demonstrated significant inhibition of mold growth, achieving an average of 35% of the sample area, while the chopped raw LCB achieved ~75%, respectively [52].

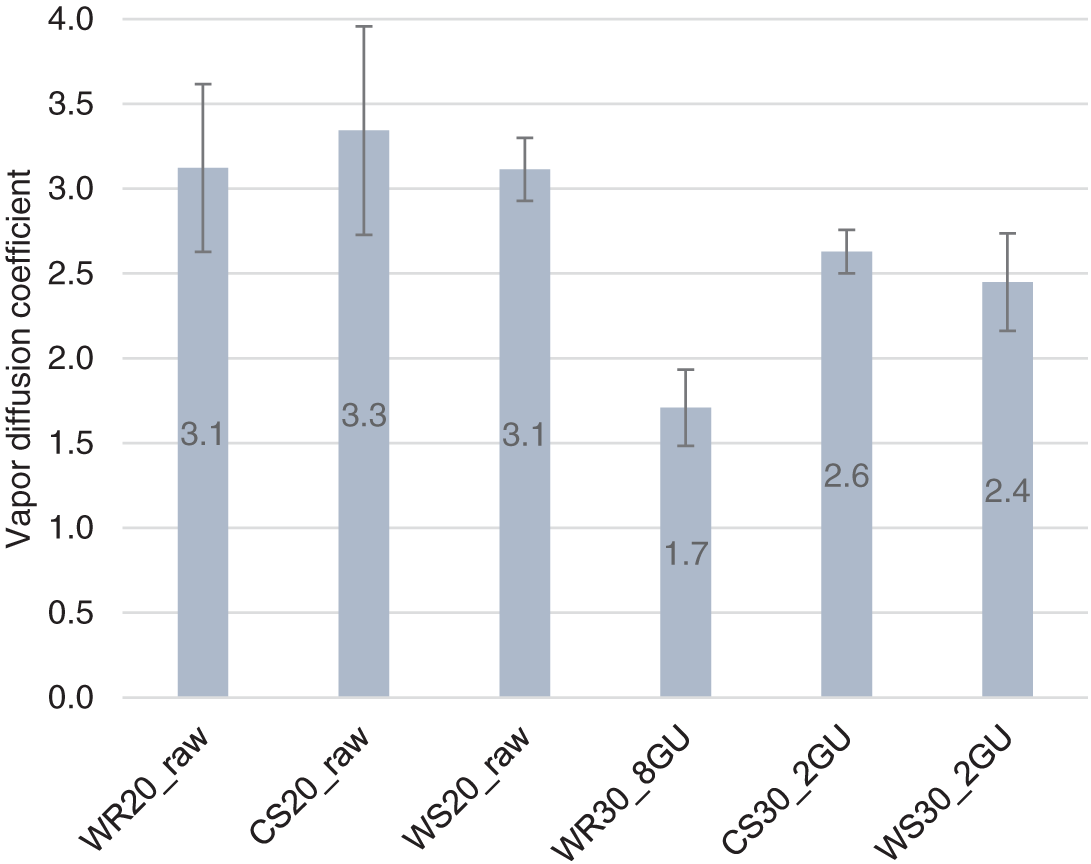

3.2.5 Analysis of Vapor Diffusion Coefficient (VDC)

Results of VDC of developed loose-fill insulation materials are shown in Fig. 6, demonstrating a significant decrease after CMP. The lowest VDC (1.72 ± 0.22) was achieved in the reed sample after CMP, while the highest (3.34 ± 0.61) depends on the untreated corn stover sample. The variation tendency of VDC is similar to WRV in terms of the highest and lowest values within the untreated and CMP samples. This indicates the differences between species independent of the processing. To mitigate the risk of condensation, particularly when indoor and outdoor humidity differentials increase, a lower VDC of insulation material is preferable [53]. A commercial loose-fill insulation material derived from softwood TMP and tested in the framework of this study showed a VDC of 2.66 ± 0.12, indicating a very similar result compared to the developed CMP samples.

Figure 6: Vapor diffusion coefficient of LCB

As the thermal conductivity of insulation material is dependent on its moisture content [7], it is essential to prevent the formation of moisture in structures and facilitate its drying. Since the VDC of developed CMPs is relatively low, the materials can dry quickly, ensuring good moisture transfer to the outside. Compared to mineral wool, with a VDC of 1, the moisture transfer is advantageously directed outwards but presents a risk of condensation in contact with the exterior cladding materials. Therefore, walls insulated with mineral wool need a water vapor retarder [54] that could be avoided in the case of LCB-based insulations.

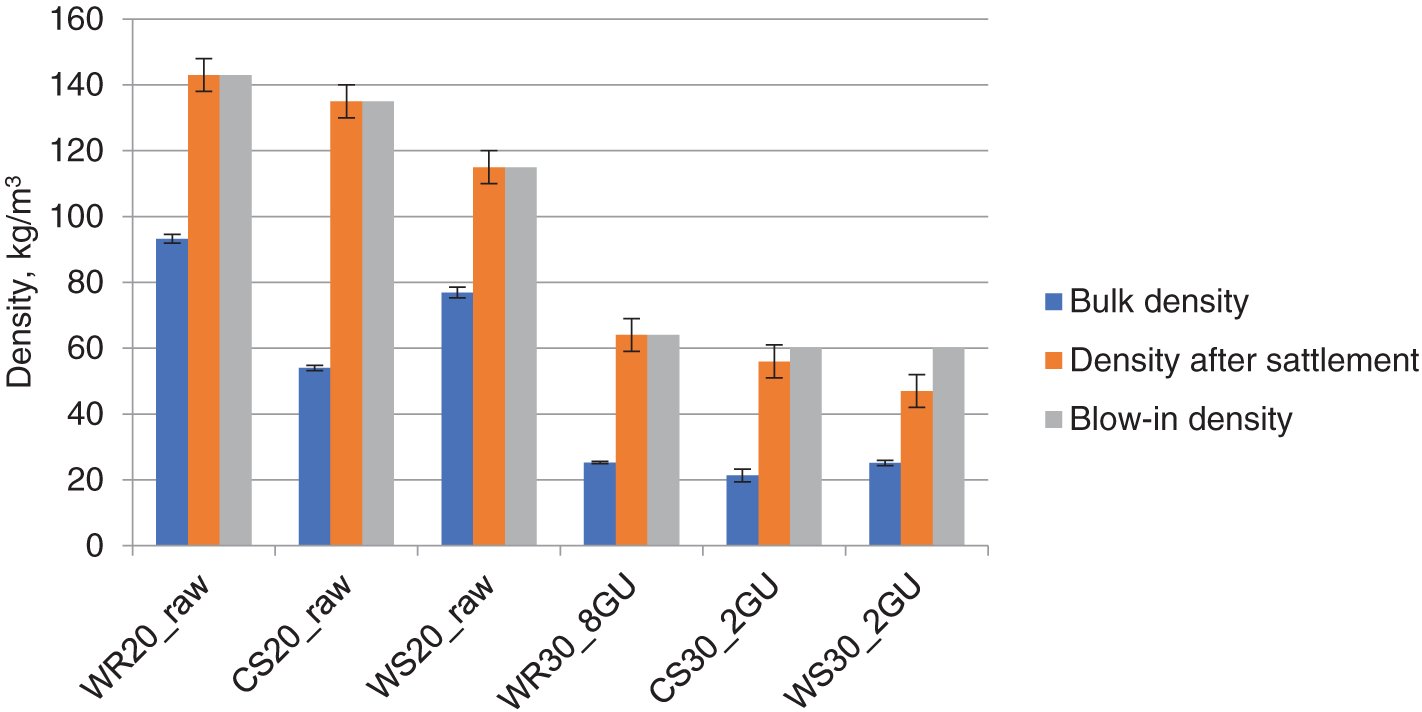

The density of loose-fill insulation material is an essential factor influencing thermal performance, settlement, and resource consumption. One of the risk factors for loose-fill insulation is settlement, which is the tendency of the material to compact under the influence of natural vibration. Therefore, the density of developed loose-fill materials was detected in bulk and settling ways (Section 2.4). The density after the settling is essential for calculating the minimum required material volume (area density) for integration into a construction. The optimal blown-in (installed) density is also determined to ensure maximum material efficiency. The summary of the densities measured during the study is presented in Fig. 7.

Figure 7: Density of loose-fill Insulation materials depending on testing

The required density affects the amount of material needed for insulation, while the thermal conductivity coefficient determines the necessary thickness of the insulation layer. Therefore, the material should be installed at a density that ensures the lowest thermal conductivity coefficient and prevents material settlement during service life. At the same time, using the least amount of material in construction is desirable to promote efficient resource use and minimize environmental impact. The bulk density of untreated CM varies in a range of 54–93 kg/m3, with the lowest value belonging to the reed sample (Fig. 7). CMP significantly impacted variation and decreased bulk density for all three plant species, achieving values between 21 and 25 kg/m3.

The density after the settlement significantly increased to 2.5× for CM and 2.7× for CMP samples. For comparison, the settling density of WS-CM measured within this study (115 kg/m3) is slightly higher than that used in another study (90–105 kg/m3) testing the blow-in technologies of chopped wheat straw [55]. The optimal density values equal to blow-in density were achieved after settling all CM and WR-CMP samples (Fig. 7). The optimal blow-in density values of CS-CMP and WS-CMP were slightly higher than after the settlement; however, all CMP samples achieved the optimal blow-in density of around 60 kg/m3. Therefore, the settling effect due to vibration aligns with the recommended minimum blowing density, meaning that only a small increase in material quantity is necessary to achieve the desired operational density. Due to the substantially higher densities of chopped raw materials, a more robust construction framework would be required to accommodate the additional material weight and settling effects. The results reveal CMP’s efficiency in producing lightweight insulation materials with adequate resource consumption. The potential impact of moisture and aging on the settlement of developed materials should be considered, which could contribute further to the compaction over time [56]. However, the performed study on chopped wheat straw declares that the blow-in insulation with a density of 105 kg/m3 increased in volume by only 3% and remained permanently stable [55].

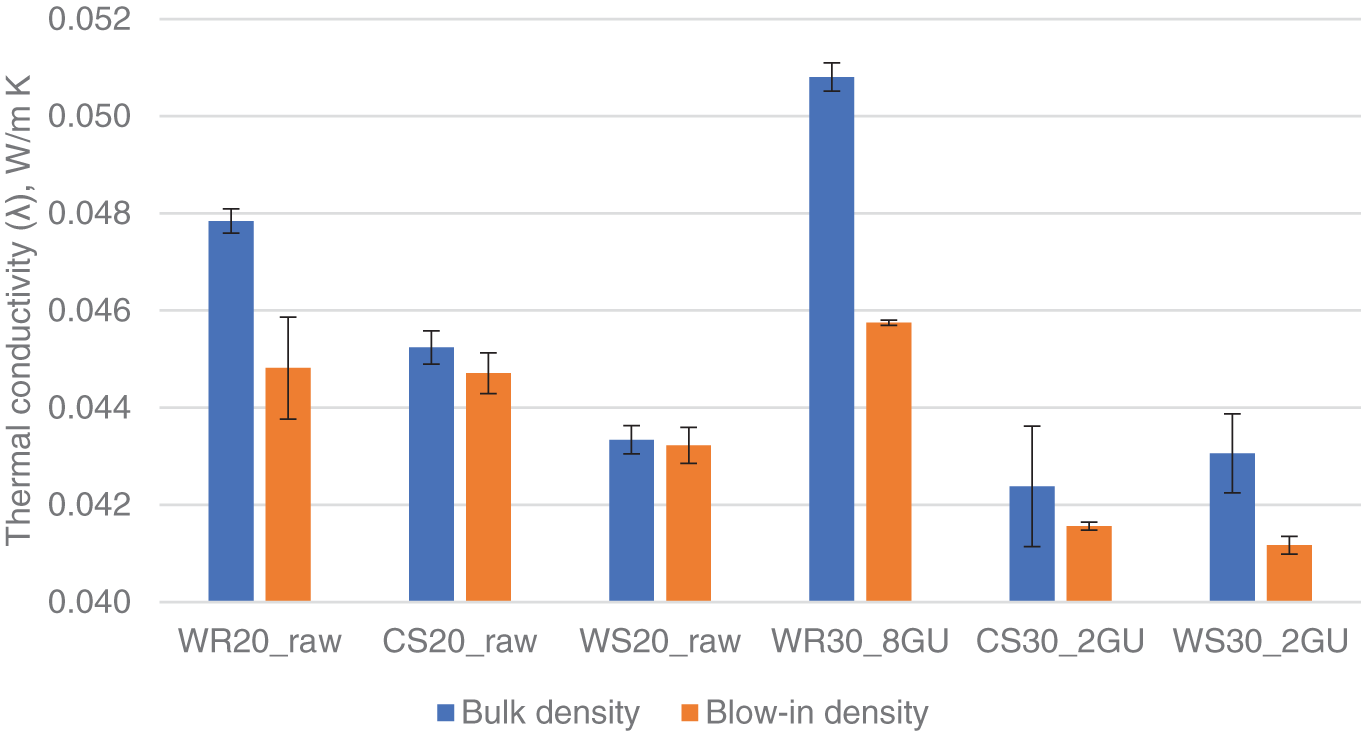

3.2.7 Analysis of Thermal Conductivity

According to the standard EN 15101-1+A1 [38] thermal conductivity of loose-fill insulation material should be determined and compared at its bulk and blow-in (the actual density in the construction) density levels. Based on this, the thermal conductivity values of developed insulation materials are summarized in Fig. 8. As shown in Fig. 8, the thermal conductivity of all developed insulation materials ranges from 0.041 to 0.051 W/mK.

Figure 8: Thermal conductivity of developed insulations at bulk and blow-in density

At the bulk density, the thermal conductivity is slightly higher than in construction, indicating the positive impact of material compaction during the blowing. Moreover, at the blow-in density, the thermal conductivity range of all developed insulation materials narrows between 0.041 and 0.046 W/mK. The determined standard deviation of thermal conductivity is relatively low, except for three samples (WR-raw at blow-in density, CS-CMP, and WS-CMP at bulk density) demonstrating a higher deviation between 0.0008 and 0.0012 W/mK. As can be seen, the dispersion of thermal conductivity is greater at bulk density but smaller at blow-in density. This can be attributed to the fact that the samples are manually placed into the test container at a given density. The arrangement of fibers in the test sample with bulk density may vary more, which affects the determined thermal conductivity. Another fact is that the homogeneity of the samples may affect the measurement, e.g., CM is lower homogenous than CMP, increasing the dispersion of thermal conductivity.

The measured low thermal conductivity indicates that all plants considered are suitable for use as loose-fill insulation in frame construction. A recent study investigating different LCB-based loose-fill thermal insulations in a wooden frame depending on climate conditions for three years has declared the thermal conductivity under 0.052 W/mK [54]. The same conclusion was confirmed by a study on chopped wheat straw blown in different ways with measured mean thermal conductivity values in the range of 0.0463–0.0471 W/mK [55]. Compared to industrially produced wood fiber and cellulose, which have a thermal conductivity of 0.038 and 0.039 W/mK, respectively [57,58], our results of CS-CMP and WS-CMP are relatively close. Comparing CM and CMP materials, it is evident that CMP has a relatively minor impact on their thermal conductivity, improving the values for corn and wheat residues and, unfortunately, slightly worsening for reeds (Fig. 8). It can be concluded that CMP minimally affects thermal conductivity.

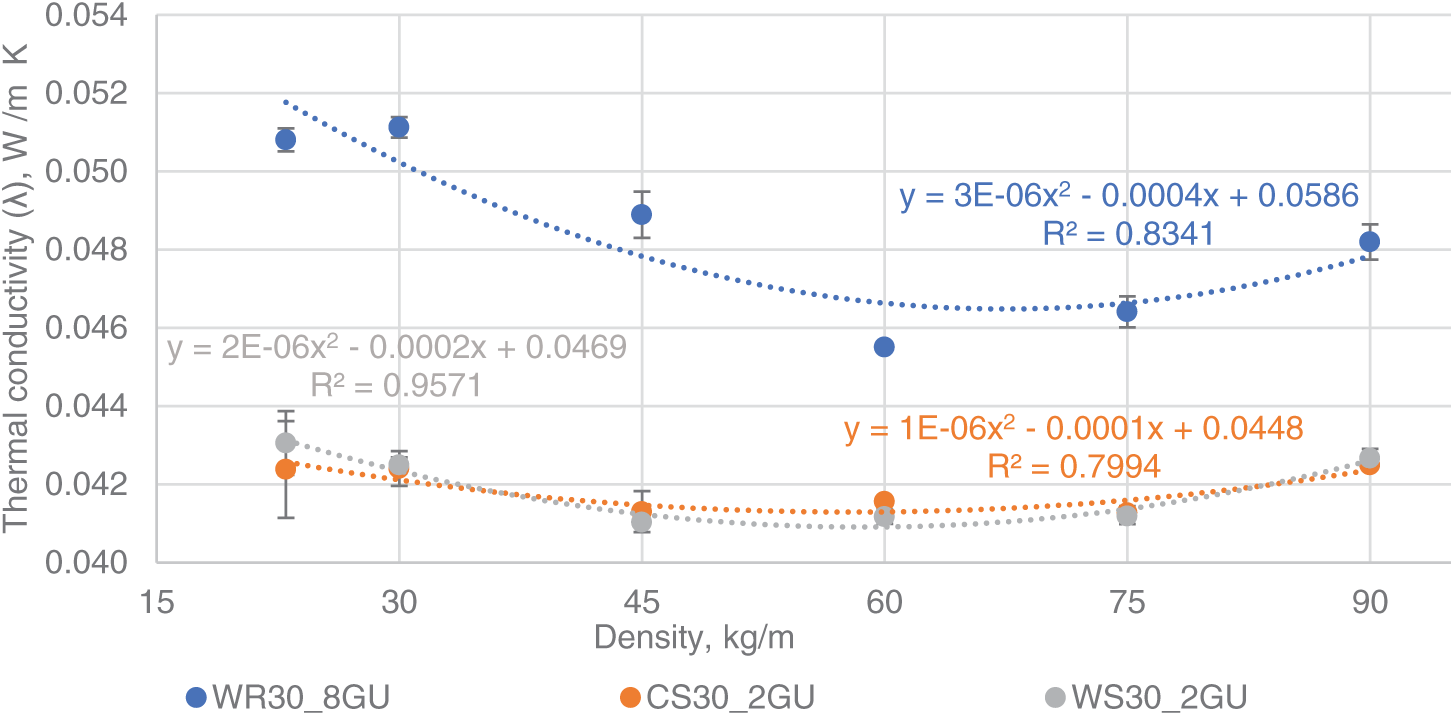

To evaluate the thermal conductivity of CMP materials, their performance was assessed at density levels varying from bulk (~23 kg/m3) up to 90 kg/m3 (Fig. 9).

Figure 9: Thermal conductivity vs. density of CMP samples

The results clearly show the shape of thermal conductivity described by significant polynomial regressions, achieving the optimal values for all samples at 60 kg/m3 density ranging from 0.041 to 0.046 W/mK. At this density level, the obtained thermal conductivity values of developed CMP fit the values of commonly used thermal insulation materials ranging between 0.03 and 0.05 W/mK [59]. Similar results of density-dependent thermal conductivity have been reported for the plant fiber insulations from hemp, flax, and jute, with the lowest values observed at the density of 70–80 kg/m3 [60]. The thermal conductivity increases in wheat straw and paper cellulose mixture as density rises from 50 to 100 kg/m3 [61]. As density increases from 18 to 85 kg/m3 for hemp fibers, the thermal conductivity decreases from 0.076 to 0.040 W/(mK) [62]. Studies on insulation boards from cotton stalk fibers also indicate higher densities and increased thermal conductivity, with density examined in the 150 to 450 kg/m3 [63].

These findings suggest that raw plant species, processing, and density significantly affect the thermal conductivity of developed insulation. The structural properties of plant materials and processing techniques can optimize this density point. A key advantage of plant-based loose-fill insulation is the ability to achieve a lower density than board materials, resulting in improved thermal conductivity and lower raw material consumption.

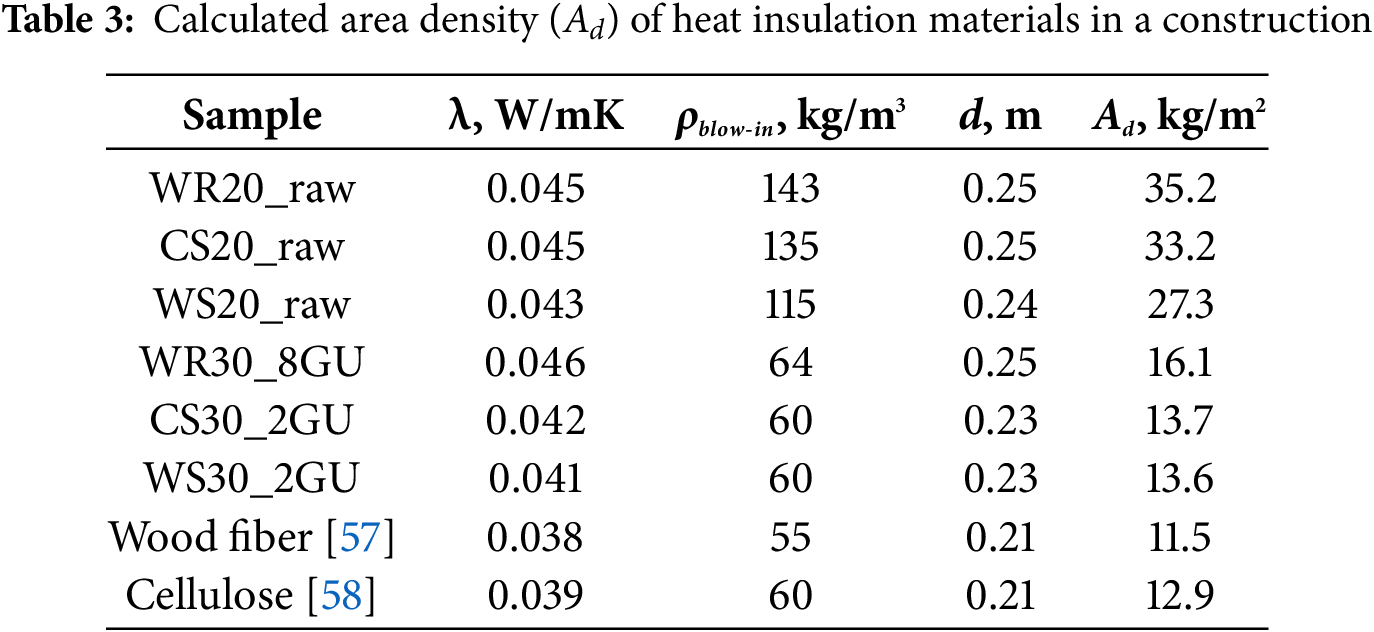

3.2.8 Material Consumption of Developed Loose-Fill Insulation

The thickness of an insulation layer is directly dependent on the thermal conductivity. Assuming that the thermal resistance (R-value) of the wall insulation is 5.5 (m2·K/W) [64], the required insulation layer thickness d (m) can be calculated using the Eq. (6):

where λ is the thermal conductivity of insulation material (W/mK). The amount of heat insulation necessary to blow in one square meter of a construction Ad (area density, kg/m2) can be calculated from Eq. (7):

where ρ is the blow-in density, kg/m3. Based on the measured values of developed loose-fill insulation materials and calculations using Eqs. (6) and (7), the results are summarized in Table 3.

Comparing the developed insulation materials, it is evident that CMP insulation requires half the amount of CM insulation to blow in one square meter of construction. This reduction is due to the lower density and thermal conductivity of developed CMP. To achieve the equivalent thermal performance of developed insulation materials compared to commercially available wood fiber or cellulose insulation, a 10%–19% thicker layer would be required. Compared to commercial cellulose insulation, only 6% more is needed in terms of area density if both CS-CMP and WS-CMP are used. This highlights the efficiency of developed CMP insulation materials from available LCB residuals regarding material usage and performance.

Although CMP requires additional processing, it enables the production of loose-fill thermal insulation with significantly lower material consumption than untreated chopped plant-based material. The properties of CMP materials are comparable to those available in the market, making it feasible to classify plant residues as suitable raw materials for application in thermal insulation. From the perspective of sustainable circular economy and environmental conservation, this approach offers significant potential. By reducing GHG emissions in terms of sequestering CO2, plant-based insulation obtained by CMP presents a promising product for environmentally sustainable applications in wood-based materials and construction sectors to promote eco-friendly building practices.

The study results show that annual plant residuals like water reed, corn stalk, and wheat straw can be converted to loose-fill thermal insulation materials by simple chopping and low-concentration chemimechanical pulping. Both methods provide good thermal conductivity for all developed insulation materials ranging between 0.041 and 0.046 W/mK. The CMP offers slightly lower thermal conductivity than CM, but only for corn and wheat samples; however, the density of blow-in CMPs (~60 kg/m3) is more than twice lower than that of CMs (115–143 kg/m3). The measured thermal performance and density after the settlement of developed insulations provided the data for the estimation of the material consumption in construction with a calculated wall thickness of 0.23–0.25 m, ranging from 27.3–35.2 kg/m2 for CMs and 13.6–16.1 kg/m2 for CMPs. The higher density of CMs would require a higher material amount and a higher-strength construction during the blowing. The measured vapor diffusion coefficient of the developed materials ranges from 1.5 to 4, providing a favorable vapor transmission and reducing the risks of mold development.

The developed plant-based thermal insulation materials compete with conventional materials available on the market. Therefore, they could supplement the bio-based market by promoting GHG reduction, responsible use of renewable resources, and eco-friendly building practices. Further research will show the long-term performance of developed insulation materials in terms of compaction, biological resistance, and thermal insulation properties during application.

Acknowledgement: The authors are incredibly thankful to the Latvian State Institute of Wood Chemistry colleagues for providing the necessary equipment for the study, especially to Dr.sc.ing. Prans Brazdausks for performing chemical analysis.

Funding Statement: The study was funded by the Latvian Council of Science, the project “Investigation of Eco-Friendly Thermal Insulation Materials from Sustainable and Renewable Industrial Crops Residuals,” number lzp-2021/1-0599.

Author Contributions: Study conception and design: Ramunas Tupciauskas, Martins Andzs, Andris Berzins; data collection: Andris Berzins, Gunars Pavlovics; analysis and interpretation of results: Andris Berzins, Ramunas Tupciauskas, Martins Andzs; draft manuscript preparation: Andris Berzins, Ramunas Tupciauskas. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Upon reasonable request.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

Nomenclature

| CMP | Chemimechanical pulp/process |

| GHG | Greenhouse gas |

| LCB | Lignocellulosic biomass |

| WS | Wheat straw |

| WR | Water reed |

| CS | Corn stalks |

| CM | Chopped material |

| WRV | Water retention value |

| VDC | Vapor diffusion coefficient |

| λ | Coefficient of thermal conductivity |

References

1. Li D, Huang G, Zhang G, Wang J. Driving factors of total carbon emissions from the construction industry in Jiangsu Province. China J Clean Prod. 2020;276(6):123179. doi:10.1016/j.jclepro.2020.123179. [Google Scholar] [CrossRef]

2. Liang Y, Pan Y, Yuan X, Yang Y, Fu L, Li J, et al. Assessment of operational carbon emission reduction of energy conservation measures for commercial buildings: model development. Energy Build. 2022;268(3):112189. doi:10.1016/j.enbuild.2022.112189. [Google Scholar] [CrossRef]

3. World Green Building Council. Whole life carbon vision. Markham, ON, Canada: World Green Building Council; 2024. [Google Scholar]

4. European Comission. A european green deal. Brussels, Belgium: European Comission; 2021. [Google Scholar]

5. Ibn-Mohammed T, Greenough R, Taylor S, Ozawa-Meida L, Acquaye A. Operational vs. embodied emissions in buildings—a review of current trends. Energy Build. 2013;66(6):232–45. doi:10.1016/j.enbuild.2013.07.026. [Google Scholar] [CrossRef]

6. Zerari S, Franchino R, Pisacane N. Industry experts’ perspectives on the difficulties and opportunities of the integration of bio-based insulation materials in the European construction sector. Sustainability. 2024;16(17):7314. doi:10.3390/su16177314. [Google Scholar] [CrossRef]

7. Hung Anh LD, Pásztory Z. An overview of factors influencing thermal conductivity of building insulation materials. J Build Eng. 2021;44(3):102604. doi:10.1016/j.jobe.2021.102604. [Google Scholar] [CrossRef]

8. Mahlia TMI, Taufiq BN, Ismail, Masjuki HH. Correlation between thermal conductivity and the thickness of selected insulation materials for building wall. Energy Build. 2007;39(2):182–7. doi:10.1016/j.enbuild.2006.06.002. [Google Scholar] [CrossRef]

9. Jiang D, Lv S, Cui S, Sun S, Song X, He S, et al. Effect of thermal insulation components on physical and mechanical properties of plant fibre composite thermal insulation mortar. J Mater Res Technol. 2020;9(6):12996–3013. doi:10.1016/j.jmrt.2020.09.009. [Google Scholar] [CrossRef]

10. Berzins A, Tupciauskas R, Andzs M, Pavlovichs G. Potential of some latvian industrial crops residuals for conversion to bio-based thermal insulation material. Mater Sci Forum. 2022;1071:139–46. doi:10.4028/p-0x7bv2. [Google Scholar] [CrossRef]

11. Tupciauskas R, Berzins A, Pavlovics G, Bikovens O. Optimization of thermal conductivity vs. bulk density of steam-exploded loose-fill annual lignocellulosics. Materials. 2023;16(10):3654. doi:10.3390/ma16103654. [Google Scholar] [PubMed] [CrossRef]

12. Rojas C, Cea M, Iriarte A, Valdés G, Navia R, Cárdenas-R JP. Thermal insulation materials based on agricultural residual wheat straw and corn husk biomass, for application in sustainable buildings. Sustain Mater Technol. 2019;20:e00102. doi:10.1016/j.susmat.2019.e00102. [Google Scholar] [CrossRef]

13. Elissetche JP, Puentes C, Vidal C, Pereira M, Melin V. Waste biomass of wine industry: a potential application of unbleached fibers produced by green approach. Biomass Convers Bior. 2022;12(11):4971–8. doi:10.1007/s13399-020-00981-x. [Google Scholar] [CrossRef]

14. Dolores Gómez-Sánchez M, Sánchez R, Espinosa E, Rosal A, Rodríguez A. Production of cellulosic pulp from reed (Phragmites australis) to produce paper and paperboard. Bioprocess Eng. 2017;1(3):65–8. doi:10.11648/j.be.20170103.11. [Google Scholar] [CrossRef]

15. del Río JC, Gutiérrez A, Rodríguez IM, Ibarra D, Martínez ÁT. Composition of non-woody plant lignins and cinnamic acids by Py-GC/MS, Py/TMAH and FT-IR. J Anal Appl Pyrolysis. 2007;79(1–2):39–46. doi:10.1016/j.jaap.2006.09.003. [Google Scholar] [CrossRef]

16. Janiszewska D, Żurek G, Martyniak D, Bałęczny W. Lignocellulosic biomass of C3 and C4 perennial grasses as a valuable feedstock for particleboard manufacture. Materials. 2022;15(18). doi:10.3390/ma15186384. [Google Scholar] [PubMed] [CrossRef]

17. Cintura E, Nunes L, Esteves B, Faria P. Agro-industrial wastes as building insulation materials: a review and challenges for Euro-Mediterranean countries. Ind Crops Prod. 2021;171:113833. doi:10.1016/j.indcrop.2021.113833. [Google Scholar] [CrossRef]

18. Liu LF, Li HQ, Lazzaretto A, Manente G, Tong CY, Liu QB, et al. The development history and prospects of biomass-based insulation materials for buildings. Renew Sustain Energy Rev. 2017;69(10):912–32. doi:10.1016/j.rser.2016.11.140. [Google Scholar] [CrossRef]

19. Azeez MA. Pulping of non-woody biomass. Pulp Pap Process. 2018;24(7):1213–32. doi:10.5772/intechopen.79749. [Google Scholar] [CrossRef]

20. Halvarsson S. Manufacture of straw MDF and fibreboards [maters’s thesis]. Sundsvall, Sweden: Mid Sweden University; 2010. [Google Scholar]

21. Korjenic A, Petránek V, Zach J, Hroudová J. Development and performance evaluation of natural thermal-insulation materials composed of renewable resources. Energy Build. 2011;43(9):2518–23. doi:10.1016/j.enbuild.2011.06.012. [Google Scholar] [CrossRef]

22. Hellová KE, Unčík S, Cabanová T. Sorption properties of thermal insulation composed of flax or hemp fibers. Slovak J Civ Eng. 2020;28(3):47–52. doi:10.2478/sjce-2020-0023. [Google Scholar] [CrossRef]

23. Muzyczek M. The use of flax and hemp for textile applications. In: Handbook of natural fibres. Volume 2: processing and applications. Amsterdam, The Netherlands: Elsevier; 2020. p. 147–67 doi: 10.1016/b978-0-12-818782-1.00004-3. [Google Scholar] [CrossRef]

24. Samdin SM, Hong YT, Mustapha M. Investigation on properties of recycled agricultural fibres as rope alternatives to jute. Asian J Fundam Appl Sci. 2022;3(2):24–33. doi:10.55057/ajfas.2022.3.2.3. [Google Scholar] [CrossRef]

25. Sridach W. The environmentally benign pulping process of non-wood fibers. Suranaree J Sci Technol. 2010;17(2):105–23. [Google Scholar]

26. Urdaneta F, Kumar R, Marquez R, Vera RE, Franco J, Urdaneta I, et al. Evaluating chemi-mechanical pulping processes of agricultural residues: high-yield pulps from wheat straw for fiber-based bioproducts. Ind Crops Prod. 2024;221(2):119379. doi:10.1016/j.indcrop.2024.119379. [Google Scholar] [CrossRef]

27. Sarmin SN. Lightweight building materials of geopolymer reinforced wood particles aggregate—a review. Appl Mech Mater. 2015;802:220–4. doi:10.4028/www.scientific.net/amm.802.220. [Google Scholar] [CrossRef]

28. Illikainen M. Mechanisms of thermomechanical pulp refining. Oulu, Finland: Acta Universitatis Ouluensis; 2008. [Google Scholar]

29. Ashaari Z, Salim S, Halis R, Yusof MNM, Sahri MH. Characteristics of pulp produced from refiner mechanical pulping of tropical bamboo (Gigantochloa scortechinii). Pertanika J Trop Agric Sci. 2010;33(2):251–8. [Google Scholar]

30. Zhao R, Guo H, Yi X, Gao W, Zhang H, Bai Y, et al. Research on thermal insulation properties of plant fiber composite building material: a review. Int J Thermophys. 2020;41(6):1–18. doi:10.1007/s10765-020-02665-0. [Google Scholar] [CrossRef]

31. Bakatovich A, Gaspar F, Boltrushevich N. Thermal insulation material based on reed and straw fibres bonded with sodium silicate and rosin. Constr Build Mater. 2022;352:129055. [Google Scholar]

32. Cosentino L, Fernandes J, Mateus R. A review of natural bio-based insulation materials. Energies. 2023;16(12):4676. doi:10.3390/en16124676. [Google Scholar] [CrossRef]

33. Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D. Determination of ash in biomass. Golden, CO, USA: National Renewable Energy Laboratory; 2008. Technical Report NREL/TP-510-42622. [Google Scholar]

34. Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, et al. Determination of structural carbohydrates and lignin in biomass. Golden, CO, USA: National Renewable Energy Laboratory; 2008. Technical Report NREL/TP-510-42618. [Google Scholar]

35. EN 15149-1. Solid biofuels—determination of particle size distribution—part 1: oscillating screen method using sieve apertures of 1 mm and above. Brussels, Belgium: European Committee; 2010. [Google Scholar]

36. EN 12086. Thermal insulating products for building applications. Determination of water vapour transmission properties. Brussels, Belgium: European Committee; 2007. [Google Scholar]

37. EN 15103. Solid biofuels—determination of bulk density. Brussels, Belgium: European Committee; 2009. [Google Scholar]

38. EN 15101-1+A1. Thermal insulation products for buildings—in-situ formed loose fill cellulose (LFCI) products—part 1: specification for the products before installation. Brussels, Belgium: European Committee; 2019. [Google Scholar]

39. Veitmans K, Grinfelds U. Wood fibre insulation material. Res Rural Dev. 2016;2:91–8. [Google Scholar]

40. Han G, Deng J, Zhang S, Bicho P, Wu Q. Effect of steam explosion treatment on characteristics of wheat straw. Ind Crops Prod. 2010;31(1):28–33. doi:10.1016/j.indcrop.2009.08.003. [Google Scholar] [CrossRef]

41. Worku LA, Bachheti A, Bachheti RK, Rodrigues Reis CE, Chandel AK. Agricultural residues as raw materials for pulp and paper production: overview and applications on membrane fabrication. Membranes. 2023;13(2):228. doi:10.3390/membranes13020228. [Google Scholar] [PubMed] [CrossRef]

42. Aghajanzadeh S, Fayaz G, Soleimanian Y, Ziaiifar AM, Turgeon SL, Khalloufi S. Hornification: lessons learned from the wood industry for attenuating this phenomenon in plant‐based dietary fibers from food wastes. Compr Rev Food Sci Food Saf. 2023;22(1):4–45. doi:10.1111/1541-4337.13047. [Google Scholar] [PubMed] [CrossRef]

43. Jelle BP. Traditional, state-of-the-art and future thermal building insulation materials and solutions—properties, requirements and possibilities. Energy Build. 2011;43(10):2549–63. doi:10.1016/j.enbuild.2011.05.015. [Google Scholar] [CrossRef]

44. Banavath HN, Bhardwaj NK, Ray AK. A comparative study of the effect of refining on charge of various pulps. Bioresour Technol. 2011;102(6):4544–51. doi:10.1016/j.biortech.2010.12.109. [Google Scholar] [PubMed] [CrossRef]

45. Marrakchi Z, Khiari R, Oueslati H, Mauret E, Mhenni F. Pulping and papermaking properties of Tunisian Alfa stems (Stipa tenacissima)—effects of refining process. Ind Crops Prod. 2011;34(3):1572–82. doi:10.1016/j.indcrop.2011.05.022. [Google Scholar] [CrossRef]

46. Jeong SY, Lee JW. Hydrothermal treatment. In: Pretreatment of biomass: processes and technologies. Amsterdam, The Netherlands: Elsevier; 2015. p. 61–74. [Google Scholar]

47. Joutsimo OP, Asikainen S. Effect of fiber wall pore structure on pulp sheet density of softwood kraft pulp fibers. BioResources. 2013;8(2):2719–37. doi:10.15376/biores.8.2.2719-2737. [Google Scholar] [CrossRef]

48. Pilon G, Duquette S, Lamothe J patricepatrice, Michaud G. Autohydrolysis of White Birch (Betula papyrifera) and Poplar (Populus) in laboratory batch digester; characterization of solids for bioenergy and/or subsequent conversions. In: CSBE/SCGAB, 2018 Annual Conference University of Guelph; 2018 Jul 22–25; Guelph, ON, Canada. Ottawa, ON, Canada: The Canadian Society for Bioengineering; 2018. 11 p. [Google Scholar]

49. Pan M, Zhou D, Zhou X, Lian Z. Improvement of straw surface characteristics via thermomechanical and chemical treatments. Bioresour Technol. 2010;101(20):7930–4. doi:10.1016/j.biortech.2010.05.022. [Google Scholar] [PubMed] [CrossRef]

50. Greenwood MS, Panetta PD, Bond LJ, McCaw MW. Ultrasonic sensor to characterize wood pulp during refining. Ultrasonics. 2006;44:2–5. doi:10.1016/j.ultras.2006.07.008. [Google Scholar] [PubMed] [CrossRef]

51. Mancini G, Papirio S, Lens PNL, Esposito G. Increased biogas production from wheat straw by chemical pretreatments. Renew Energy. 2018;119:608–14. doi:10.1016/j.renene.2017.12.045. [Google Scholar] [CrossRef]

52. Tupciauskas R, Orlovskis Z, Blums KT, Liepins J, Berzins A, Pavlovics G, et al. Mold fungal resistance of loose-fill thermal insulation materials based on processed wheat straw, corn stalk and reed. Polymers. 2024;16(4):562. doi:10.3390/polym16040562. [Google Scholar] [PubMed] [CrossRef]

53. BademliOglu AH, Kaynakli Ö, Yamankaradeniz N. The effect of water vapor diffusion resistance factor of insulation materials for outer walls on condensation. ISI Bilim Ve Tek Dergisi/J Therm Sci Technol. 2018;38(2):15–23. [Google Scholar]

54. Kosiński P, Patyna K. Practical use of materials of natural origin as loose-fill insulations in open-diffusion constructions—observation and numerical simulation. Sustainability. 2024;16(11):4593. doi:10.3390/su16114593. [Google Scholar] [CrossRef]

55. Salonen T, Fischer H, Korjenic A. Chopped straw as an insulation material: the influence of different blow-in technologies and flame retardants on hygrothermal properties. Buildings. 2023;13(10):2555. doi:10.3390/buildings13102555. [Google Scholar] [CrossRef]

56. Rasmussen TV. Prediction of density for prevention of settling of hygroscopic and Nonhygroscopic loose-fill insulation in walls. J Therm Envel Build Sci. 2005;28(3):245–67. doi:10.1177/1097196305048596. [Google Scholar] [CrossRef]

57. Hunton Nativo. Handbook of wood fibre insulation [Internet]. 2024 [cited 2024 Dec 21]. Available from: https://hunton.dk/produkter/vegg/hunton-nativo-traefiberisolering-plader/. [Google Scholar]

58. EKOWOOL. EKOWOOL Premium S [Internet]. 2024 [cited 2024 Dec 21]. Available from: https://ekoiso.com/lv/PRODUKTI/. [Google Scholar]

59. Berardi U, Naldi M. The impact of the temperature dependent thermal conductivity of insulating materials on the effective building envelope performance. Energy Build. 2021;144(4):262–75. doi:10.1016/j.enbuild.2017.03.052. [Google Scholar] [CrossRef]

60. Korjenic A, Zach J, Hroudová J. The use of insulating materials based on natural fibers in combination with plant facades in building constructions. Energy Build. 2016;116(3):45–58. doi:10.1016/j.enbuild.2015.12.037. [Google Scholar] [CrossRef]

61. Soto M, Rojas C, Cárdenas-Ramírez JP. Characterization of a thermal insulating material based on a wheat straw and recycled paper cellulose to be applied in buildings by blowing method. Sustainability. 2023;15(1):58. doi:10.3390/su15010058. [Google Scholar] [CrossRef]

62. Kosiński P, Brzyski P, Szewczyk A, Motacki W. Thermal properties of raw hemp fiber as a loose-fill insulation material. J Nat Fibers. 2018;15(5):717–30. doi:10.1080/15440478.2017.1361371. [Google Scholar] [CrossRef]

63. Zhou X-Y, Zheng F, Li H-G, Lu C-L. An environment-friendly thermal insulation material from cotton stalk fibers. Energy Build. 2010;42(7):1070–4. doi:10.1016/j.enbuild.2010.01.020. [Google Scholar] [CrossRef]

64. Hietikko J, Tuominen E, Valovirta I, Vinha J. Timber-framed exterior walls insulated with wood shavings: a field study in a nordic climate. Build Environ. 2024;254:111371. doi:10.1016/j.buildenv.2024.111371. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools