Open Access

Open Access

ARTICLE

Thermal Performance Analysis of Shell and Tube Heat Exchanger Using Hybrid Nanofluids Based on Al2O3, TiO2, and ZnO Nanoparticles

1 Department of Mechanical Engineering, Mehran University of Engineering and Technology, Jamshoro, 76080, Pakistan

2 Department of Mechanical & Industrial Engineering, College of Engineering, Qatar University, Doha, P.O. Box 2713, Qatar

* Corresponding Author: Laveet Kumar. Email:

(This article belongs to the Special Issue: Innovative Heat Transfer Fluids for Enhanced Energy Sustainability in Thermal Systems)

Frontiers in Heat and Mass Transfer 2025, 23(3), 833-856. https://doi.org/10.32604/fhmt.2025.064805

Received 24 February 2025; Accepted 17 April 2025; Issue published 30 June 2025

Abstract

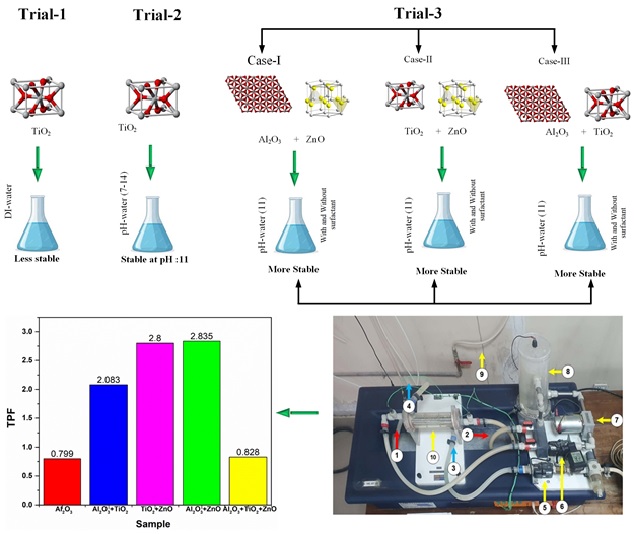

Climate change, rising fuel prices, and fuel security are some challenges that have emerged and have grown worldwide. Therefore, to overcome these obstacles, highly efficient thermodynamic devices and heat recovery systems must be introduced. According to reports, much industrial waste heat is lost as flue gas from boilers, heating plants, etc. The primary objective of this study is to investigate and compare unary (Al2O3) thermodynamically, binary with three different combinations of nanoparticles namely (Al2O3 + TiO2, TiO2 + ZnO, Al2O3 + ZnO) and ternary (Al2O3 + TiO2 + ZnO) as a heat transfer fluid. Initially, three different types of binary nanofluids were prepared by dispersing two types of nanoparticles in individual trails, such as aluminum oxide, zinc oxide, and titanium dioxide in various combined concentrations (e.g., 2%, 4%, and 6%) into the water as the base fluid, using an ultrasonicator to ensure uniform suspension. The operating parameters such as nanoparticle concentration and flow rate are varied to evaluate the performance of various hybrid nanofluids under counterflow configuration. The findings of this research indicate that the binary nanofluid Al2O3 + ZnO exhibits the highest thermal performance factor (2.83), followed by the ternary nanofluid Al2O3 + TiO2 + ZnO (0.828), with the lowest performance observed for the unary nanofluid Al2O3 (0.799). This research highlights the need for advancement into novel nanomaterial combinations, optimization of required fluid properties, stability enhancement, and thermal performance to strengthen the utilization of hybrid nanofluids in heat exchangers.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools