Advancing Sustainable Materials: Nano-Palm Kernel Shell Biochar (n-PKSB) and Nano-Activated Biochar (n-APKS) as Renewable Fillers in Natural Rubber (NR) Biocomposites

Nur ‘Aisyah Ar-Raudhoh Mohammad Tahar1, Muhammad Haziq Mohd Fadzli1, Siti Nur Liyana Mamauod1,2,*, Nahrul Hayawin Zainal3

1 Faculty of Applied Sciences, Universiti Teknologi MARA, Shah Alam, 40450, Malaysia

2 Centre for Chemical Synthesis and Polymer Technology, Institute of Science, Universiti Teknologi MARA, Shah Alam, 40450, Malaysia

3 Biomass Technology Unit, Engineering and Processing Division, Malaysian Palm Oil Board, No. 6, Persiaran Institusi, Bandar Baru Bangi, Kajang, 43000, Malaysia

* Corresponding Author: Siti Nur Liyana Mamauod. Email:

(This article belongs to the Special Issue: Biomass-based Thermoset and Thermoplastic Polymers for Biomass-based Composites)

Journal of Renewable Materials https://doi.org/10.32604/jrm.2025.02025-0177

Received 11 September 2025; Accepted 25 November 2025; Published online 18 December 2025

Abstract

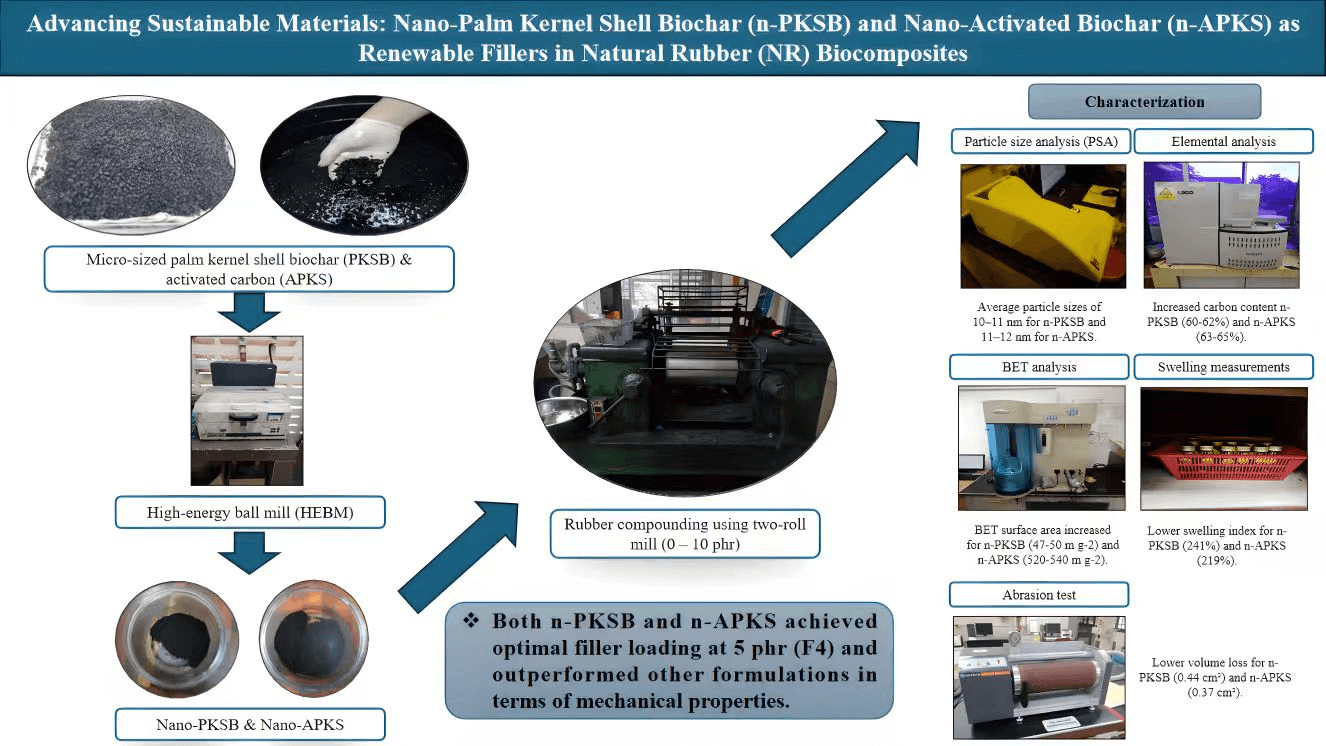

The palm oil industry is a major contributor to Malaysia’s economy, but its huge production has generated large amounts of oil palm biomass, particularly palm kernel shell (PKS), which poses environmental challenges if not properly managed. Converting PKS into biochar (PKSB) and activated carbon (APKS) offers a sustainable way to valorise this waste as potential bio-fillers in rubber composites. This study investigates the influence of nano-sized PKSB (n-PKSB) and activated PKS (n-APKS) as bio-fillers on the mechanical performance of natural rubber (NR) vulcanizates, with filler loadings ranging from 0 to 10 parts per hundred rubber (phr). The fillers were characterized using particle size analyzer (PSA), elemental analyzer, and Brunauer–Emmett–Teller (BET) analysis, while the filled NR vulcanizates were evaluated through swelling and abrasion tests. The PSA results showed average particle sizes of 10–11 nm for n-PKSB and 11–12 nm for n-APKS. The carbonization-activation process increased the carbon content (63%–65%) and BET surface area (520–540 m g

−2) of n-APKS compared to n-PKSB (60%–62% and 47–50 m g

−2, respectively). These enhancements promote stronger filler–rubber interfacial bonding and improved stress transfer within the matrix. Consequently, n-APKS-filled NR exhibited lower swelling index (219%) and volume loss (0.37 cm

3) than n-PKSB filled NR vulcanizates (241% and 0.44 cm

3), indicating better resistance to solvent penetration and abrasive forces. Both fillers achieved their optimal results at 5 phr loading. Thus, n-APKS and n-PKSB have potential as bio-fillers that will enhance rubber properties while reducing palm oil waste and contributing to long-term mitigation of environmental impact.

Graphical Abstract

Keywords

Characterization; bio-filler reinforcement; mechanical properties; morphological analysis; rubber-filler interaction

Open Access

Open Access